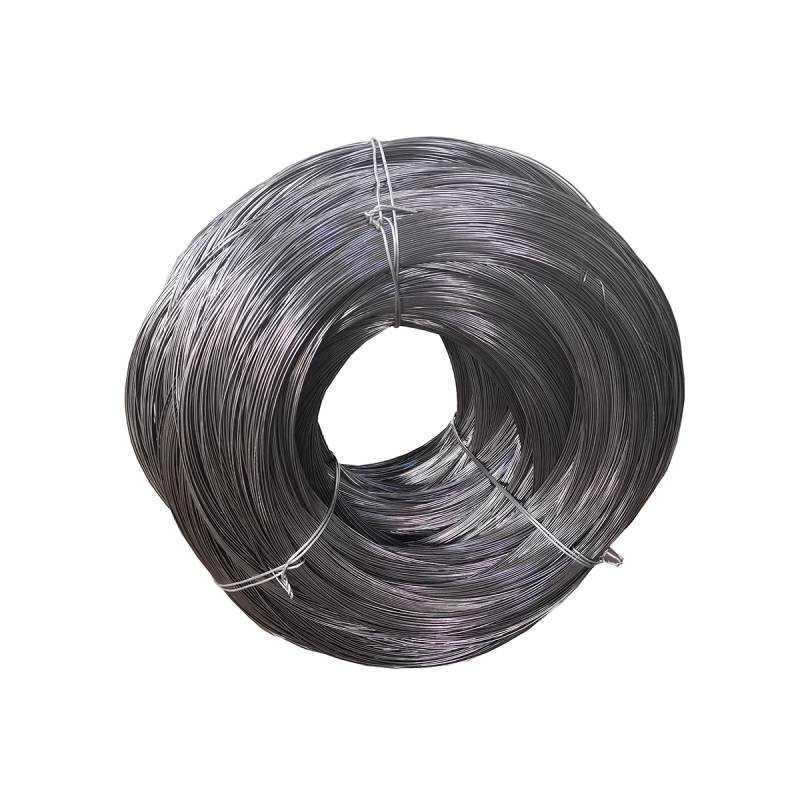

Material: Black annealed wire, also referred to as black iron wire, soft annealed wire, or annealed iron wire, is made from carbon steel wire.

Annealing Process: The wire undergoes thermal annealing, a process that enhances its flexibility and softness by removing oxygen.

Increased Elongation: The annealing process increases the elongation of the wire, making it softer and more versatile for a wider range of applications.

Post-Treatment: The wire can be further processed with galvanizing, hot-dip galvanizing, or copper plating for added durability and corrosion resistance.

Applications

- Wire Mesh Production: Widely used in manufacturing wire mesh for construction, agriculture, and industrial purposes.

- Construction: Commonly used for reinforcing, tying, and binding in construction projects.

- Agricultural Use: Ideal for creating fences, supports, and other agricultural structures.

- General Industry: Suitable for various industries where flexibility, softness, and corrosion resistance are required.

Parameters Table

|

Name |

Black annealed wire |

black annealed cut iron wire |

black annealed binding tie wire |

|

Wire Guage |

BWG8 ~ 26# |

AWG8 ~ 26# |

SWG8 ~ 26# |

|

Wire Diameter |

4mm ~ 0.46mm |

4mm ~ 0.46mm |

4mm ~ 0.46mm |

|

Material |

Q195 or as needed |

||

|

Coil weight |

10-100KGS |

||

|

Tensile Strength |

30KGS/mm²— 55KGS/mm² |

||

|

Wire Gauge Size |

SWG(mm) |

BWG(mm) |

BG(mm) |

|

8 |

4.06 |

4.19 |

3.988 |

|

9 |

3.66 |

3.76 |

3.551 |

|

10 |

3.25 |

3.40 |

3.175 |

|

11 |

2.95 |

3.05 |

2.827 |

|

12 |

2.64 |

2.77 |

2.517 |

|

13 |

2.34 |

2.41 |

2.24 |

|

14 |

2.03 |

2.11 |

1.994 |

|

15 |

1.83 |

1.83 |

1.775 |

|

16 |

1.63 |

1.65 |

1.588 |

|

17 |

1.42 |

1.47 |

1.412 |

|

18 |

1.22 |

1.25 |

1.257 |

|

19 |

1.02 |

1.07 |

1.118 |

|

20 |

0.91 |

0.89 |

0.996 |

|

21 |

0.81 |

0.813 |

0.887 |

|

22 |

0.71 |

0.711 |

0.749 |

|

23 |

0.61 |

0.635 |

0.707 |

|

24 |

0.56 |

0.559 |

0.629 |

|

25 |

0.51 |

0.508 |

0.56 |

|

26 |

0.46 |

0.457 |

0.498 |

Black Anneal Wire