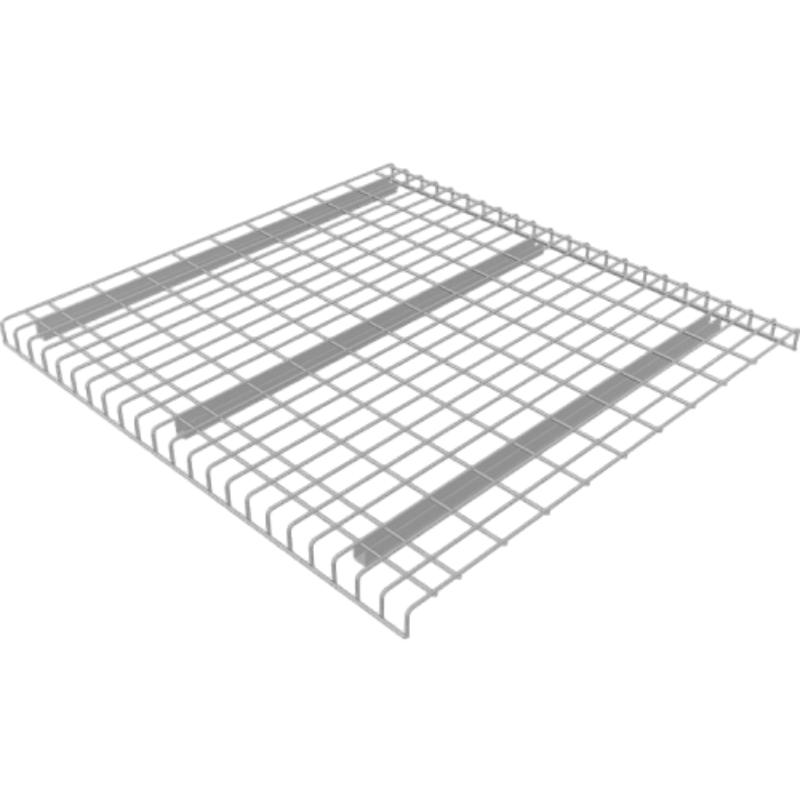

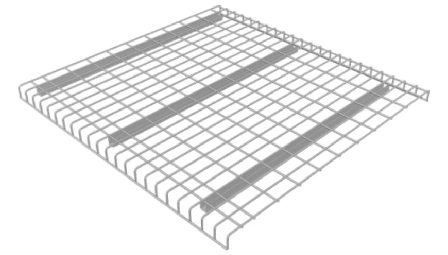

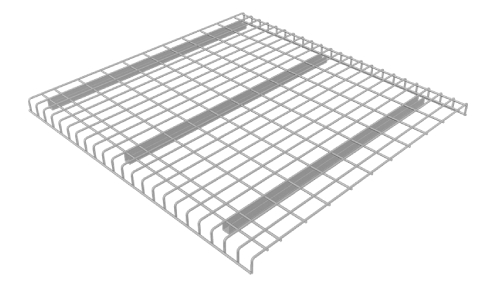

- Our wire mesh decking is designed to provide additional safety for warehouse pallet rack applications throughout your warehouse.

- We provide high-quality powder coating wire mesh decking and can also manufacture custom sizes and styles for all storage and pallet rack requirements.

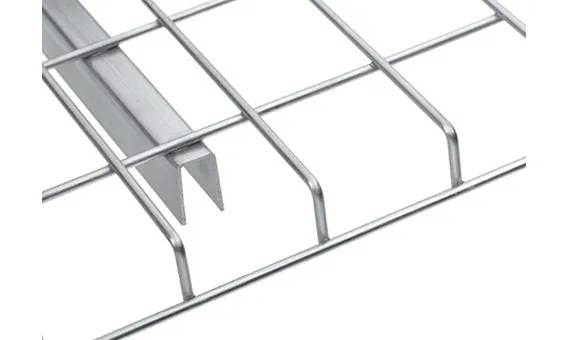

- Standard 2-1/2” x 4” x 6 ga. Wire mesh pattern

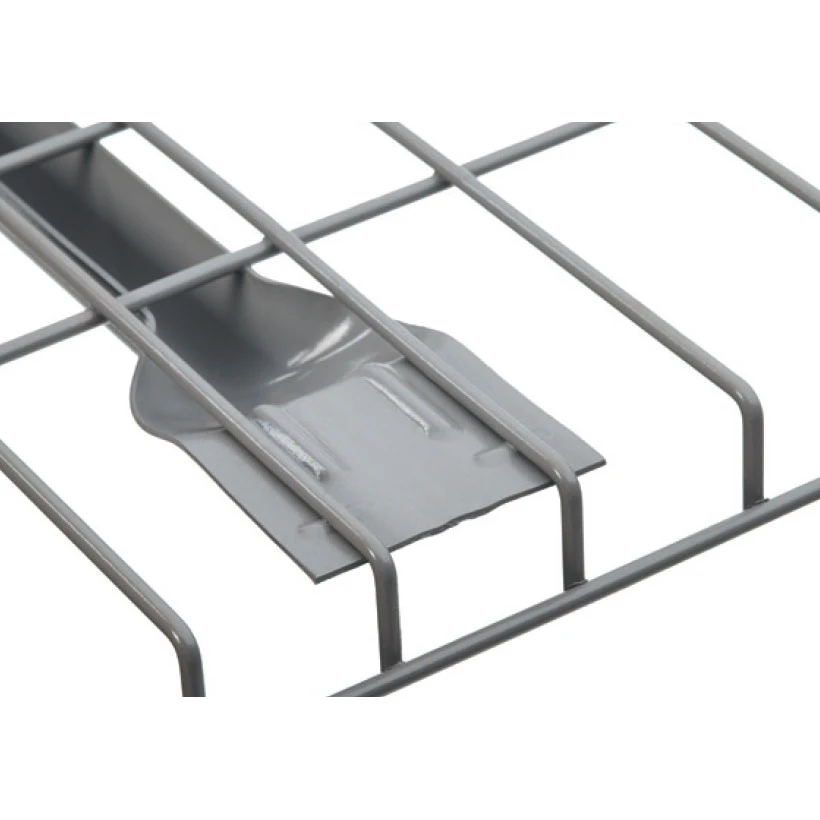

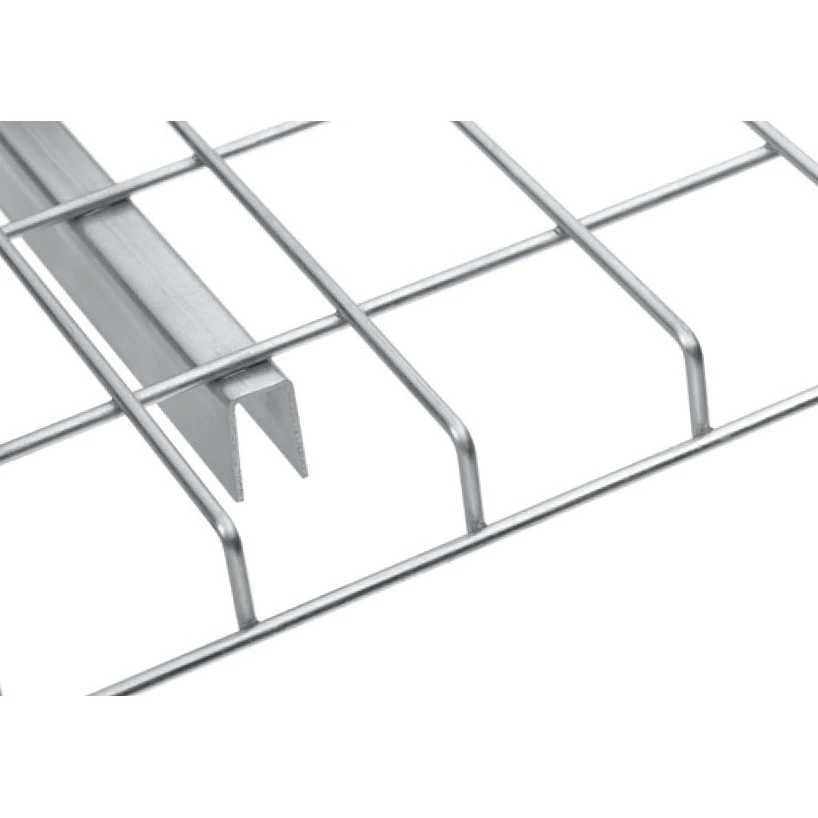

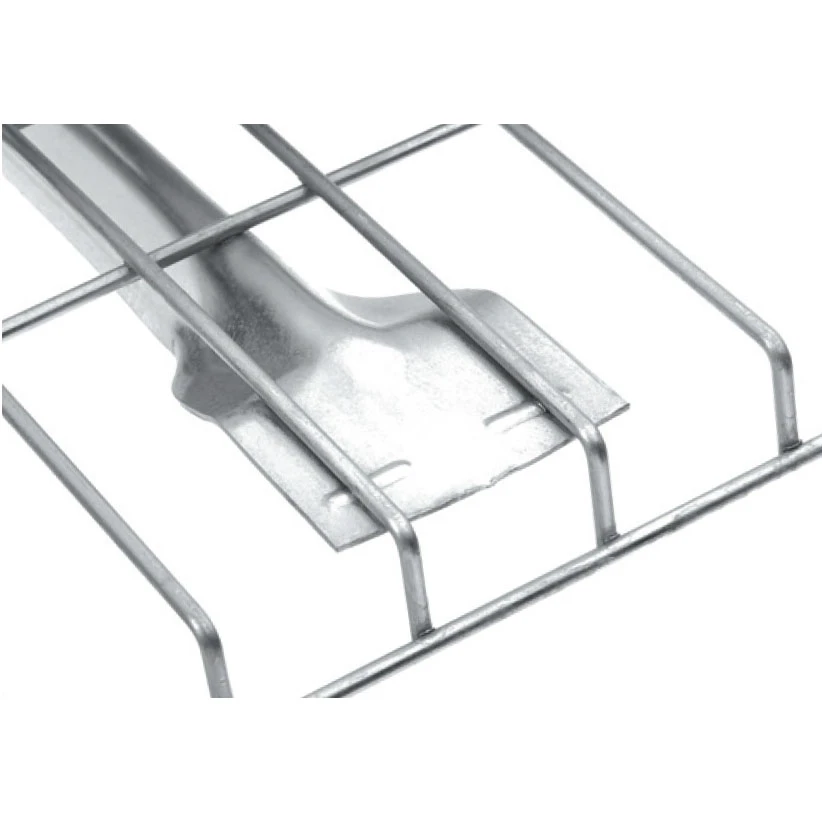

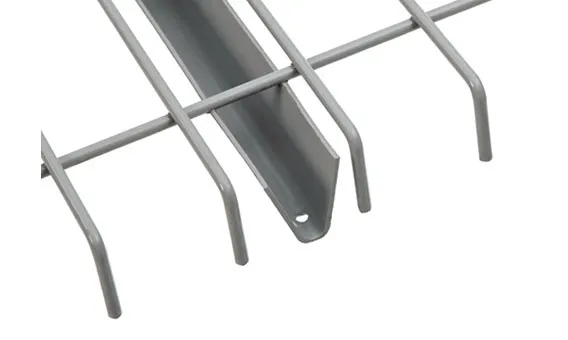

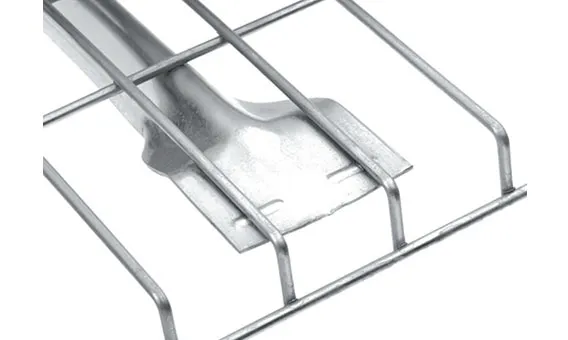

- 14ga & 16ga support channels

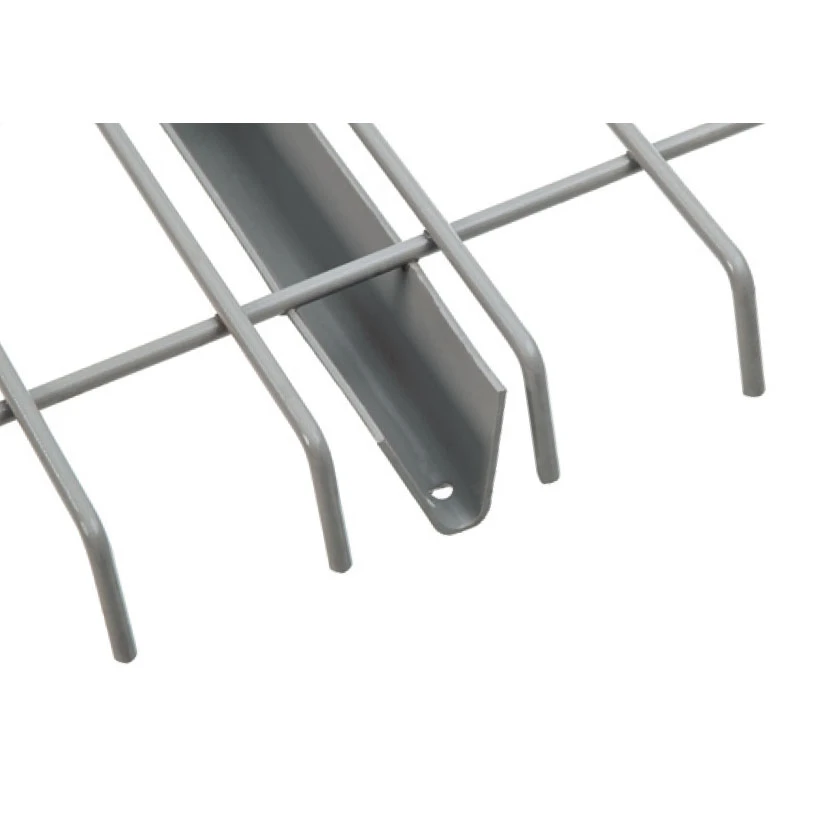

- 1.5” waterfall front and rear

- High quality heavy-duty gray powder coating finish

- Capacities based on UDL(uniformly distributed load)

EURO& AUSTRALIA SIZES

|

DEPTH(mm) |

WIDTH(mm) |

MESH(mm) |

WIRE DIA(mm) |

SUPPORT |

CAP.(kg) |

|

|

TYPE

|

N.O

|

|||||

|

1000 |

880 |

50*100 |

5 |

FLARED |

3 |

800 |

|

1050 |

880 |

50*100 |

5 |

FLARED |

3 |

800 |

|

1100 |

880 |

50*100 |

5 |

FLARED |

3 |

800 |

|

1000 |

1340 |

50*100 |

5 |

FLARED |

4 |

1000 |

|

1050 |

1340 |

50*100 |

5 |

FLARED |

4 |

1000 |

|

1100 |

1340 |

50*100 |

5 |

FLARED |

4 |

1000 |

|

840 |

1250 |

50*100 |

5 |

FLARED |

4 |

1000 |

|

840 |

1350 |

50*100 |

5 |

FLARED |

4 |

1000 |

|

900 |

1118 |

50*100 |

5 |

FLARED |

3 |

800 |

|

1100 |

1118 |

50*100 |

5 |

FLARED |

3 |

800 |

|

900 |

1320 |

50*100 |

5 |

FLARED |

4 |

1000 |

|

1100 |

1320 |

50*100 |

5 |

FLARED |

4 |

1000 |

AMERICA SIZES

|

DEPTH(inch) |

WIDTH(inch) |

MESH(inch) |

WIRE DIA(gauge) |

SUPPORT |

CAP.(kg) |

|

|

TYPE

|

N.O

|

|||||

|

24 |

46 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

3000 |

|

30 |

46 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

3000 |

|

36 |

46 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

2700 |

|

36 |

52 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

2500 |

|

36 |

58 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

2750 |

|

42 |

46 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

2800 |

|

42 |

52 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

2500 |

|

42 |

58 |

2.5*4.5 |

5 |

U-SHAPE |

4 |

2800 |

|

44 |

46 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

2500 |

|

44 |

52 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

2600 |

|

44 |

58 |

2.5*4.5 |

5 |

U-SHAPE |

3 |

2500 |

|

48 |

46 |

2.5*4.5 |

5 |

U-SHAPE |

4 |

2500 |

|

48 |

52 |

2.5*4.5 |

5 |

U-SHAPE |

4 |

2500 |

|

48 |

58 |

2.5*4.5 |

5 |

U-SHAPE |

4 |

2500 |

|

60 |

46 |

2.5*4.5 |

5 |

U-SHAPE |

4 |

2500 |

The Benefits of Wire Mesh Decking for Your Warehouse Needs

In today’s fast-paced industrial environment, efficiency and safety are paramount. One of the most effective solutions for maximizing storage capabilities is wire mesh decking. This innovative product has become an essential component in warehouses and storage facilities, offering a range of benefits that enhance operational productivity.

1. Enhanced Visibility:

One of the primary advantages of wire mesh decking is its ability to improve visibility within storage areas. Unlike solid shelving options, wire mesh allows for better air circulation and visibility of the products stored above. This feature not only helps in inventory management but also aids in reducing the potential for accidents, as visibility allows workers to see what lies ahead when navigating through the aisles.

2. Increased Safety:

Wire mesh decking contributes significantly to the safety of your warehouse environment. The open design of the decking allows for the easy drainage of liquids, preventing the accumulation of spills and reducing the risk of slips and falls. Additionally, the sturdy construction of wire mesh decking provides the necessary support for heavy loads, ensuring that goods remain securely in place, even during high-traffic periods.

3. Versatility:

Wire mesh decking is versatile and can be adapted to various storage systems, including pallet racks and shelving units. This adaptability means that warehouses can change their layout easily to accommodate different types of inventory, optimizing space and improving overall efficiency. Wire mesh decking can also be used with various pallet types, enhancing compatibility and usability across your storage solutions.

4. Improved Cleanliness:

The design of wire mesh decking promotes a cleaner storage environment. Its ability to allow air circulation reduces dust accumulation and facilitates quick clean-up processes. This is particularly beneficial for industries that require strict hygiene standards, as it helps maintain a clean workspace for products that are sensitive to contamination.

Understanding Wire Decking and Its Variations: Outside Waterfall Deck, Inverted Channel Deck, Inside Waterfall Deck, Flush (Or Drop-In) Deck, Upturned Deck

Wire decking is a vital component in modern warehouse storage solutions, providing versatile support for various types of products. One of the standout features of wire decking is its ability to enhance the efficiency and safety of shelving systems. Among the numerous options available, five notable variations of wire decking emerge: Outside Waterfall Deck, Inverted Channel Deck, Inside Waterfall Deck, Flush (or Drop-in) Deck, and Upturned Deck. Understanding these types can help businesses optimize their warehouse structures for ultimate performance.

1. Outside Waterfall Deck: This design features a gentle curve that extends over the edges of the shelving unit, preventing products from slipping off while enhancing stability. The waterfall edge helps secure items and facilitates airflow, making it an excellent choice for delicate or perishable goods.

2. Inverted Channel Deck: Characterized by its reverse channel structure, the inverted channel deck provides enhanced support for heavier items. This design effectively distributes weight across the shelving unit, minimizing sagging and prolonging the lifespan of the shelves. It is particularly well-suited for industrial environments where larger, bulkier products are stored.

3. Inside Waterfall Deck: This design allows items to be positioned closer to the back of the shelf, optimizing vertical space while ensuring that products remain secure at the front. This variation is ideal for businesses that aim to maximize storage efficiency without sacrificing easy access to inventory.

4. Flush (or Drop-in) Deck: The flush deck offers a seamless surface that sits directly on the shelves, providing a clean, flat storage area. This style is particularly beneficial for storing smaller items, as it reduces the risk of them falling through any gaps and maintains a tidy appearance.

5. Upturned Deck: Featuring edges that are turned upwards, the upturned deck configuration provides extra security for product storage. This design helps to contain items on the shelving unit and is particularly useful for high-traffic areas where products might be subject to movement or jostling.

Wire Mesh Decking for Pallet Racking

In the world of warehousing and storage solutions, efficiency and safety are paramount. One of the essential components that enhance both aspects is wire mesh decking for pallet racking. This innovative solution has gained significant traction among businesses looking to optimize their storage systems.

Wire mesh decking is a type of storage platform designed to rest on pallet racking systems. It is primarily constructed from high-quality steel wire, offering a robust and durable option for supporting goods stored within a warehouse. The design of wire mesh decking allows for excellent air circulation and visibility, which can help in maintaining inventory conditions and promoting safety by reducing dust accumulation.

One of the standout features of wire mesh decking is its ability to support various product weights. Whether you're stacking heavy machinery or lighter items, wire mesh decking provides a flexible solution that can accommodate diverse storage needs. This adaptability makes it an ideal choice for industries such as manufacturing, retail, and distribution.

Moreover, the installation of wire mesh decking is straightforward. It is compatible with most standard pallet racking systems, providing a seamless upgrade that can enhance the structure's overall functionality. This ease of installation translates to reduced downtime, allowing businesses to continue their operations without significant interruptions.

Safety is another critical factor when considering storage solutions. Wire mesh decking helps to ensure that items stored on pallet racking are secure, minimizing the risk of items falling. This feature not only protects your inventory but also contributes to a safer working environment for employees.