Robert

Solar Installation Contractor (USA)

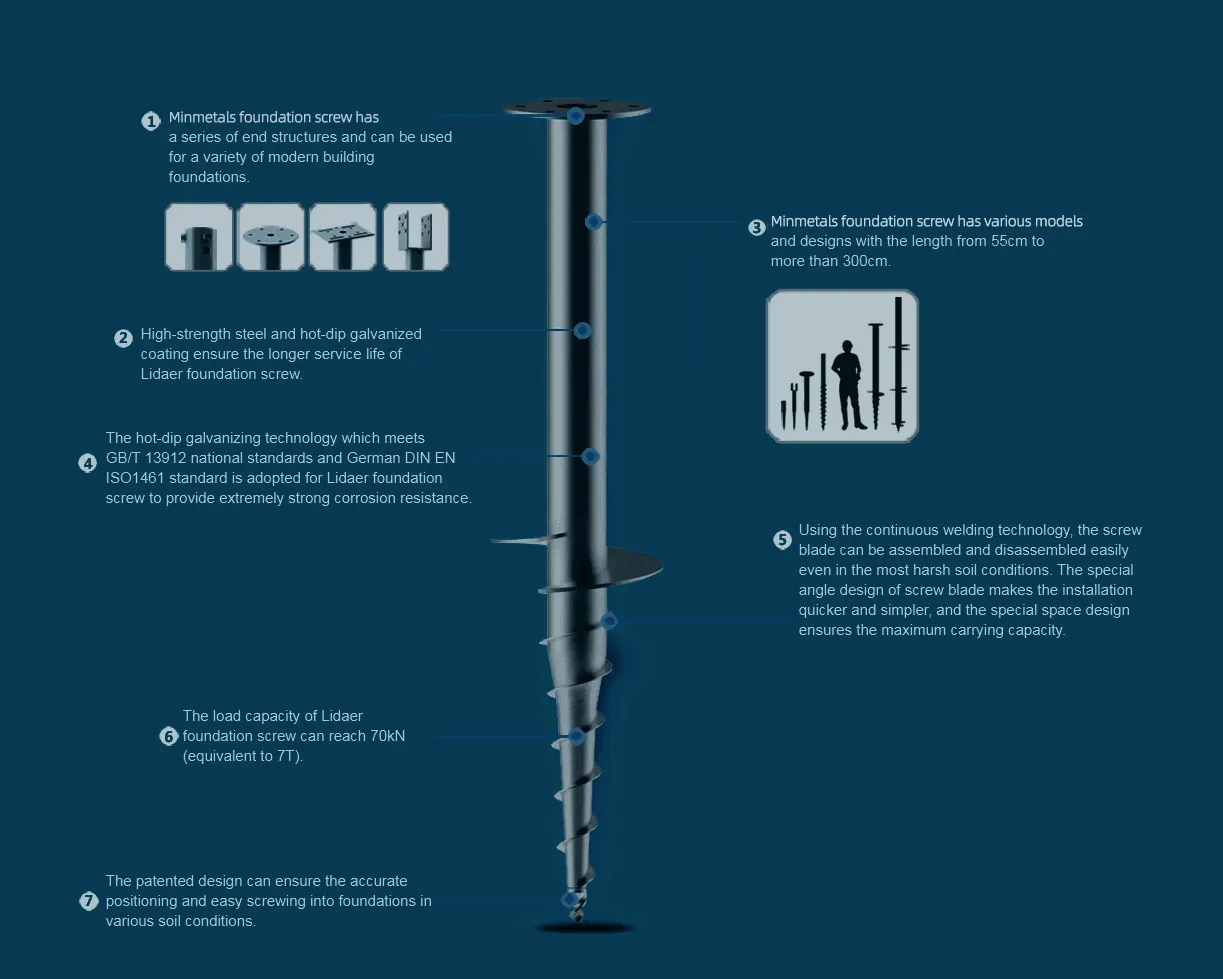

Screw-in anchors can be customized according to the needs of clients. It is widely used for the installation of house, wooden chalet and light steel structure building foundations, wooden walkway, billboard, bus stop, power tower, railway, highway, stadium, substation, family handrail, guide rail and fence foundations and photovoltaic solar energy, solar light, street light, housing construction, recreational facilities and other foundations.

Structural Features:

J series ground screws are equipped with three or four threaded screws, u shape bracket or square or round flange depending on application.

Application Range:

They are ideal for the simple and quick installation of horizontal and vertical wooden beams,easy and quick to install fence posts,masts or road signs.

J series ground screws are also widely used in the installation of solar panels walkways,bridges and housing construction etc.

Surface Treatment:

The high-quality hot-dip galvanized steels are stable and reliable. It is in accordance with German DIN EN IS0 1461 standard.

HM-JFA

Hot dip galvanized

Small blade with flange

HM-JN

Hot dip galvanized

Small blade with threaded screws

HM-JYU

Hot dip galvanized

Small blade with U shape

Structural Features:

VD series ground screws are equipped with several large blade depending on the features of soil.Threaded screws or flange can be added depending on application.

Application Range:

They are often used in structures with soft soil and high pulling force. They are easy and quick to install fence posts, masts or road signs,and are widely used in the installation of solar panels, walkways, bridges and housing construction, etc.

Surface Treatment:

The high-quality hot-dip galvanized steels are stable and reliable. It is in accordance with German DIN EN ISO 1461 standard.

HM-VD2FA

Hot dip galvanized

Single large

2D blade with flange

HM-VD4FA

Hot dip galvanized

Single large

4D blade with flange

HM-V2D2FA

Hot dip galvanized

Double large

2D blade with flange

Structural Features:

Y series ground screws are equipped with multi-stage small blade or together with large blade. Threaded screws or flange can be added depending on application.

Application Range:

They are often used in structures with clay soil, plain fill, silt, etc which is soft in lower part. They are easy and quick to install fence posts,masts or road signs, and are widely used in the installation of solar panels, walkways, bridges and housing construction, etc.

Surface Treatment:

The high-quality hot-dip galvanized steels are stable and reliable.

It is in accordance with German DIN EN IS0 1461 standard.

HM-YN

Hot dip galvanized

Multi-stage small blade with threaded screws

HM-YH

Hot dip galvanized

Multi-stage small blade with flange

HM-YHS

Hot dip galvanized

Double continuous blade with flange

HM-YDH

Hot dip galvanized

Small blade together with double large blade with flange

Ground anchors are used to stretch and secure chains, ropes, wires, ribbing ties, etc.

HM-EA

Hot dip galvanized

Ground anchor

HM-CJ belongs to the outdoor small ground pile, which is lighter and easier to carry. It is mainly used for outdoor umbrellas, tents and other temporary structures, etc.

HM-CJ

Hot dip galvanized

Outdoor ground screw

Outperform traditional foundations with ground screw anchors—the modern solution for rapid, eco-friendly structural stability. Unlike concrete footings that require excavation, curing time, and environmental disruption, ground screw anchors install in minutes using specialized equipment. They transfer structural loads directly into stable subsoil layers, providing immediate load-bearing capacity without waiting days for concrete to set. Ideal for decks, solar farms, fencing, and light buildings, this system eliminates weather delays and soil erosion risks.

Speed & Efficiency: Install anchors in hours, not days, with minimal site disturbance. No curing means projects proceed instantly.

All-Season Reliability: Frost heave? Flooding? Ground screw anchors maintain integrity where concrete cracks or shifts. Their helical design grips below frost lines, preventing seasonal movement.Zero Environmental Damage: Avoid concrete’s carbon footprint and soil contamination. Screws leave no residue and are 100% removable/reusable.

Cost Savings: Reduce labor, equipment rentals, and material waste. No mixing, pouring, or formwork required.

Technical Superiority

Engineered from hot-dip galvanized steel, these anchors withstand corrosion while supporting loads up to 50kN (varies by soil class). The helical plates compact, rather than displace soil during installation, enhancing pull-out resistance. Tests show 200% greater tensile strength versus concrete in sandy or clay-heavy soils.

The Science Behind Soil Anchoring

Concrete relies on sheer mass, while ground screw anchors use engineered friction and bearing capacity. This creates a dynamic “lock” with the earth, adapting to soil density changes that fracture static concrete. Independent studies confirm a 30% longer lifespan in high-moisture zones.

Ground screw anchors have become a go-to foundation solution across industries thanks to their speed, stability, and eco-friendliness. Hebei Minmetals’ ground screws have been widely applied in both commercial and residential projects. Below are several real-world examples where our metal ground screws delivered outstanding performance.

In a suburban residential project in Canada, homeowners opted for ground screws for fence posts instead of traditional concrete foundations. With uneven terrain and tight timelines, the installation team used Hebei Minmetals ground screws to secure fence panels. The process was completed within a single day, offering a durable, frost-resistant base without digging or curing time.

A vacation cabin in Norway utilized ground screw anchors for decks, avoiding the need for excavation in rocky soil. The project required minimal machinery, reduced labor, and eliminated the environmental impact of concrete. The elevated wooden deck has stood strong for over five years, proving the long-term stability of screw foundations in challenging terrain.

Ground screws are increasingly replacing concrete footings for light commercial buildings. One notable case was a shed base installation in the UK. By using metal ground spikes and screws, the customer achieved a secure base within hours. Similarly, a carport installation in Australia leveraged our screws to anchor steel columns, avoiding underground utilities and reducing installation costs by 40%.

4. Solar, Signage, and Towers

For a solar farm in Southeast Asia, Hebei Minmetals supplied over 2,000 ground anchors to support solar racking systems. The screws were installed without disturbing the soil’s natural profile, ensuring long-term integrity. Additionally, our screws have been used for signage posts, temporary lighting, and communication towers, where quick deployment is essential.

5. Household and Recreational Applications

In household and lifestyle projects, ground screws are gaining popularity. DIYers have used them to install garden arches, playhouses, and pergolas. Even shooting sport structures and greenhouses are now securely mounted using our products, proving that ground screws are as versatile as they are reliable.

① Prep the Site

Clear rocks/roots where screws will go.

Pro tip: Spray-paint screw locations to avoid misalignment.

② Start the Screw

Attach the drive head to your motor.

Position the screw perfectly vertical (even 5° off risks wobble).

Don’t force it: If the screw stops spinning, reverse ¼ turn – forcing it bends shafts.

③ Drive to Depth

Run the motor at 25-35 RPM (high torque, low speed).

Stop when:

Torque spikes suddenly (you’ve hit bedrock/compact layer).

Depth reaches below the frost line (check local codes – typically 4+ ft).

④ Attach Your Structure

Bolt mounting brackets directly to the screw head.

Shim for precision leveling – never bend the screw to adjust height.

3 Critical Mistakes to Avoid

Skipping Soil Checks

Sandy soil? Use wider helix plates.

Clay? Slow rotation to prevent "corking" (soil compaction around threads).

Ignoring "Refusal" Signs

If the screw won’t budge after reversing, relocate – don’t sacrifice integrity.

Over-Torquing

Excessive force strips threads. Use a gauge – most screws max at 2,500-3,500 Nm.

Robert

Solar Installation Contractor (USA)

Amelia

Event Organizer (UK)

Jorge

Farm Manager (Spain)

Mia

DIY Enthusiast (Canada)

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy