Premium U Shaped Fence Post for Sale | Galvanized & Durable

Aug . 14, 2025 01:00The Indispensable Role of U Posts in Modern Infrastructure

In the landscape of modern infrastructure and construction, the u shaped fence post stands as a cornerstone of durability and adaptability. These posts, characterized by their distinct U-shaped cross-section, are engineered to provide superior strength and stability for a myriad of applications, ranging from agricultural fencing to complex highway sign installations. The market for U Posts is currently experiencing a robust growth trajectory, driven by increasing global demand for resilient and cost-effective fencing and signage solutions. Industry trends indicate a significant shift towards materials offering enhanced corrosion resistance and longevity, making products like the galvanized u channel post particularly desirable. Furthermore, the emphasis on sustainable and long-lifecycle solutions means that manufacturers who can deliver exceptional quality and performance are gaining a competitive edge. This evolution underscores the critical importance of selecting a U Post that meets stringent structural and material specifications, ensuring both safety and long-term operational efficiency in diverse environmental conditions.

The versatility of the U Post extends across various sectors, demonstrating its capacity to perform reliably under pressure. For instance, in agricultural settings, these posts provide robust support for livestock containment and property demarcation, often specified as a dependable u post for sale due to their ease of installation and minimal maintenance requirements. Conversely, in urban and highway environments, the demand for a heavy duty u channel sign post is paramount, where structural integrity against wind loads and vehicle impacts is critical. This broad applicability highlights the need for manufacturers to offer a diverse product range, accommodating both light-duty and heavy-duty requirements. Understanding the specific material composition, load-bearing capacities, and surface treatments—such as hot-dip galvanization—is crucial for project planners and procurement specialists to ensure optimal performance and compliance with industry standards.

Understanding the Engineering Behind U Channel Posts

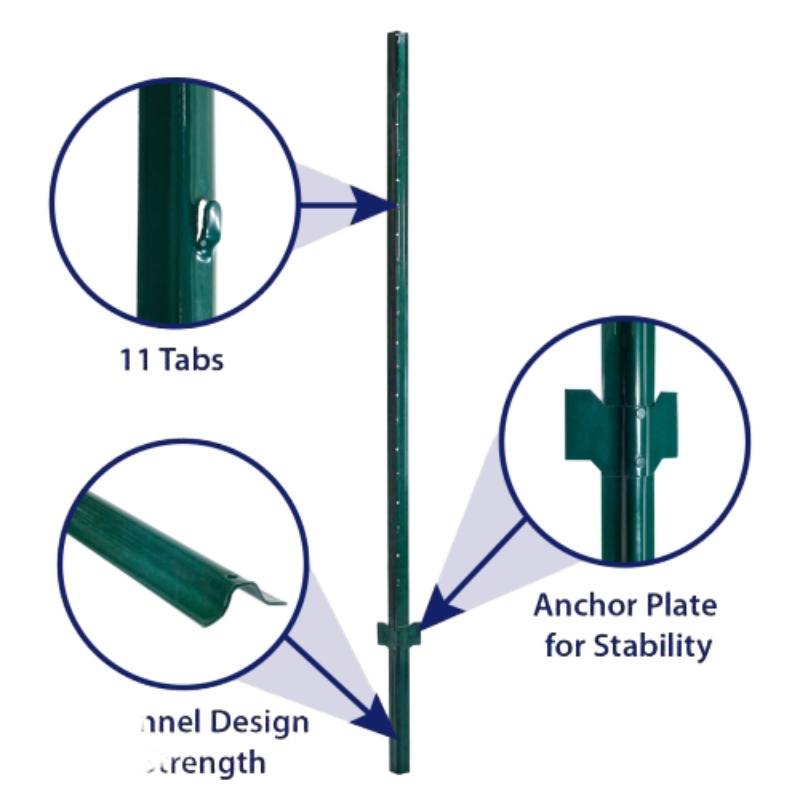

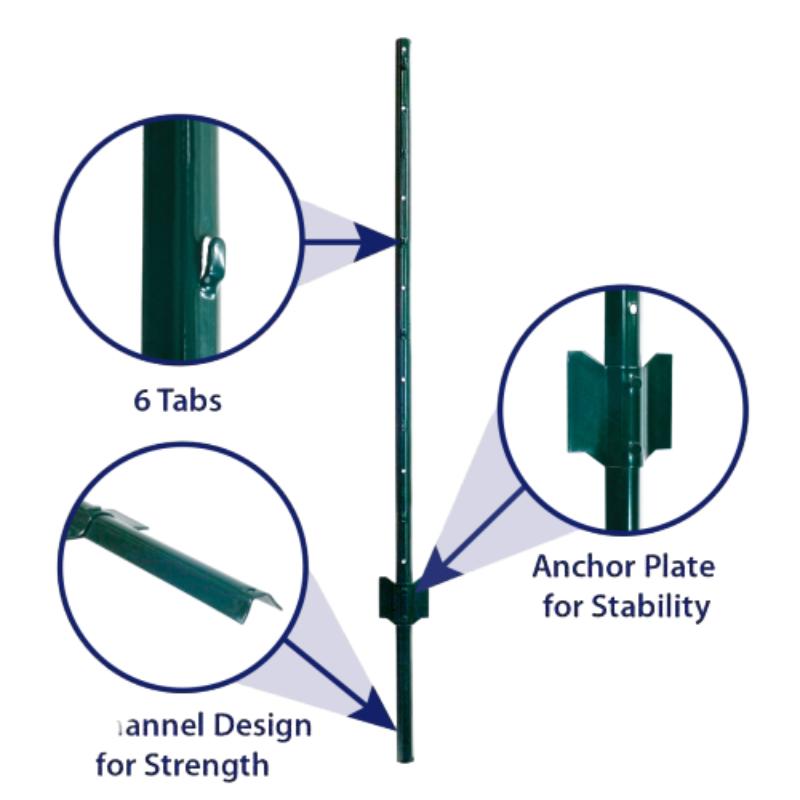

The engineering of a high-quality u shaped fence post begins with precise material selection. Typically, these posts are fabricated from high-grade carbon steel or galvanized steel, chosen for their inherent strength and resistance to environmental degradation. The U-channel profile, a distinctive design feature, offers superior resistance to bending and torsional forces compared to round or square posts of similar weight. This structural efficiency is achieved by distributing material strategically to maximize the section modulus, a critical parameter in structural engineering that quantifies resistance to bending. Technical parameters such as steel grade (e.g., Q235, Q345, or ASTM A36), wall thickness, flange width, and web depth are meticulously defined during the design phase to meet specific load-bearing requirements and industry standards like ASTM A572 for high-strength low-alloy structural steel.

The manufacturing process typically involves cold-forming or hot-rolling techniques. Cold-forming, where steel sheets are bent into the U-shape at room temperature, allows for tighter tolerances and a smoother finish, often preferred for a light duty fence post or applications where aesthetic appeal is significant. Hot-rolling, on the other hand, involves shaping heated steel through rollers, resulting in a more uniform grain structure and enhanced strength, often used for a heavy duty u channel sign post. Post-forming, a crucial step is surface treatment, most commonly hot-dip galvanization according to ISO 1461 or ASTM A123. This process applies a durable zinc coating that acts as a sacrificial layer, protecting the underlying steel from rust and corrosion, significantly extending the service life of the post, particularly in corrosive environments such as coastal regions or industrial zones, which are relevant for petrochemical and metallurgy industries.

The Manufacturing Journey: Precision and Durability

The production of a high-quality u shaped fence post involves a multi-stage process designed to ensure structural integrity and longevity. It typically begins with the selection of raw materials, primarily high-strength steel coils or plates, which are sourced from certified mills to guarantee compliance with chemical composition and mechanical property standards, such as those set by ASTM. The initial phase, often called decoiling and leveling, prepares the steel for forming by uncoiling it and flattening it into a precise sheet. Following this, the steel undergoes either cold roll forming or hot rolling. Cold roll forming is a continuous process where the steel sheet is progressively shaped through a series of rollers into the desired U-profile. This method is highly efficient for producing long lengths with consistent cross-sections and is particularly suited for creating a galvanized u channel post that requires tight dimensional tolerances.

Once formed, the posts are cut to specified lengths, and any necessary punching or drilling for mounting holes is performed. This stage requires precision CNC (Computer Numerical Control) machining to ensure accurate hole placement and size, which is critical for ease of installation and structural integrity, especially for a heavy duty u channel sign post. The most vital stage for corrosion protection is hot-dip galvanization. In this process, the fabricated steel U-posts are immersed in a bath of molten zinc at approximately 450°C (840°F). The metallurgical reaction between steel and zinc forms a series of zinc-iron alloy layers, topped by a pure zinc layer, providing superior resistance to rust and abrasion. This coating typically extends the service life by decades, especially beneficial in demanding sectors like petrochemical and wastewater treatment, where resistance to corrosive agents is paramount. Final inspection involves strict adherence to standards like ISO 9001 for quality management and ANSI/AWS standards for any welding, ensuring each U Post meets or exceeds performance expectations, including its impressive service life of 20+ years in typical environments.

Key Technical Specifications & Performance Data

Selecting the appropriate u shaped fence post requires a thorough understanding of its technical specifications. These parameters directly influence the post's performance, load-bearing capacity, and suitability for specific environments. Below is a comprehensive table outlining typical specifications for various types of U Posts available, designed to assist B2B buyers and engineers in their procurement decisions. This data is critical for ensuring compliance with project requirements and achieving optimal structural integrity. For instance, the weight per foot (or meter) is a key indicator of material density and overall strength, directly correlating with the post's ability to withstand significant forces like wind loads or soil pressure, particularly vital for a heavy duty u channel sign post.

| Parameter | Light Duty Fence Post | Standard U Post | Heavy Duty Sign Post |

|---|---|---|---|

| Material Grade | Q235B / ASTM A36 | Q345B / ASTM A572 Gr.50 | Q345B / ASTM A572 Gr.50 |

| Weight (lbs/ft) | 1.12 lbs/ft | 1.33 lbs/ft | 2.00 - 3.00 lbs/ft |

| Length (ft) | 5 - 8 ft | 6 - 12 ft | 8 - 20 ft (or custom) |

| Surface Treatment | Green Painted / Galvanized | Hot-Dip Galvanized (ASTM A123) | Hot-Dip Galvanized (ASTM A123) |

| Hole Spacing (inches) | 1 inch | 1 inch | Custom (typically 1-2 inch) |

| Corrosion Resistance | Good (Painted) to Excellent (Galv.) | Excellent (20+ years) | Superior (30+ years) |

In addition to the tabulated data, load capacity tests and salt spray tests (ASTM B117) are routinely conducted to validate the post's performance and corrosion resistance. For example, a standard galvanized u channel post with a weight of 1.33 lbs/ft can typically withstand lateral forces of up to 300 lbs when properly installed, making it suitable for boundary fencing in moderate wind zones. Heavy-duty variants, often used as signposts, are designed to endure significantly higher stresses, making them an ideal u post for sale for demanding municipal or commercial projects. These rigorous testing protocols ensure that each U Post delivers consistent, reliable performance throughout its projected service life.

Versatile Applications: Where U Posts Excel

The inherent strength, ease of installation, and exceptional durability of the u shaped fence post make it an incredibly versatile component across a broad spectrum of industries and applications. Its design, optimized for both load-bearing and stability, positions it as a preferred choice over traditional round or square posts in many scenarios. In agricultural settings, they are foundational for perimeter fencing, defining property lines, and safely containing livestock. The robustness of a u post for sale ensures fences remain upright and secure, even in challenging weather conditions or with animal pressure, contributing to significant energy savings by minimizing maintenance and repair needs over time.

Beyond agriculture, the application of U Posts extends significantly. In the transportation sector, heavy duty u channel sign post variants are indispensable for supporting road signs, traffic signals, and warning signs along highways and urban thoroughfares. Their ability to withstand high wind loads and resistance to vehicle impacts (when breakaway designs are integrated) is paramount for public safety. For utility companies, a galvanized u channel post serves as a reliable support for utility markers, boundary indicators, and even temporary enclosures around work sites. In industrial environments, such as petrochemical plants, metallurgical facilities, and wastewater treatment plants, the corrosion-resistant properties of galvanized U Posts are crucial. Here, they are used for safety barriers, demarcation of hazardous zones, and structural support in highly corrosive atmospheres, demonstrating their superior defense against chemical degradation and ensuring long-term structural integrity with minimal maintenance, leading to significant cost efficiencies and enhanced operational safety.

Why Choose Our Premium U Channel Posts: Unmatched Advantages

When considering the optimal solution for fencing or signage infrastructure, the technical advantages of a superior u shaped fence post are undeniable. Our commitment to stringent manufacturing processes and material quality ensures that each post delivers exceptional performance and longevity. A primary advantage lies in their inherent design: the U-channel profile provides a high strength-to-weight ratio, allowing for robust support without excessive material usage. This optimized geometry offers superior resistance to bending and twisting forces, crucial for maintaining structural integrity under varying environmental stresses, whether it’s a light duty fence post or a more substantial application.

Furthermore, the longevity and corrosion resistance provided by our hot-dip galvanized galvanized u channel post are unmatched. The zinc coating, applied in accordance with international standards like ISO 1461, forms a metallurgical bond with the steel, creating a formidable barrier against rust and abrasion. This extends the service life of our posts significantly, often exceeding 20-30 years, even in harsh weather conditions or corrosive industrial atmospheres like those found in the petrochemical or wastewater treatment sectors. This prolonged lifespan translates directly into reduced maintenance costs and lower total cost of ownership over the project's lifetime. Our adherence to ISO 9001 quality management systems and comprehensive testing protocols, including load-bearing and impact resistance tests, further assures that every u post for sale we supply meets the highest benchmarks of quality, reliability, and safety.

Choosing the Right Partner: Manufacturer Comparison and Custom Solutions

In the competitive market for U Posts, selecting a manufacturer that aligns with your project's specific needs and quality expectations is paramount. While many suppliers offer a u shaped fence post, significant differences exist in material quality, manufacturing precision, and post-sales support. Reputable manufacturers distinguish themselves through adherence to international standards (e.g., ISO, ANSI, ASTM), transparent testing methodologies, and a proven track record. When comparing providers, consider their capacity for large-scale production, their flexibility in offering custom solutions, and their logistics capabilities to ensure timely and cost-effective delivery, especially when sourcing a substantial volume of u post for sale.

Our company, Hebei Metals, exemplifies a commitment to excellence, backed by over 15 years of industry experience and partnerships with leading engineering firms and construction contractors globally. We specialize in providing bespoke solutions for clients requiring specific dimensions, steel grades, or surface finishes for their heavy duty u channel sign post or a more general light duty fence post. Our technical team works closely with clients from conceptualization to final delivery, offering CAD design services and material selection guidance to optimize performance and budget. We hold multiple certifications, including ISO 9001 for quality management and environmental certifications, reinforcing our authoritative standing in the industry. This comprehensive approach, combined with our rigorous quality control, positions us as a trusted partner for even the most challenging infrastructure projects.

Real-World Impact: Application Case Studies

The practical application of the u shaped fence post in various real-world scenarios demonstrates its robust performance and versatility. For a major agricultural development project in the Midwest, our galvanized u channel post was selected for over 50 miles of perimeter fencing. The client's primary concern was long-term durability against harsh weather cycles and minimal maintenance. Our solution, featuring hot-dip galvanized posts with a 1.33 lbs/ft specification, provided the required resistance to corrosion and bending, significantly reducing the anticipated replacement cycle and delivering a substantial long-term cost saving. Customer feedback highlighted the ease of installation and the professional appearance of the completed fencing system.

Another notable project involved supplying custom-fabricated heavy duty u channel sign post units for a new highway interchange near a coastal city. The challenge here was to ensure the signposts could withstand extreme wind loads (up to 120 mph) and provide superior resistance to salt spray corrosion. We engineered posts with a higher steel grade (ASTM A572 Gr.50) and a thicker zinc coating exceeding typical ASTM A123 requirements. The posts were deployed successfully, passing rigorous third-party wind load simulations. The project manager praised our responsiveness and technical expertise in delivering a tailored solution that met the demanding environmental and safety standards. These cases exemplify how a well-engineered u post for sale can be a critical element in the success and longevity of diverse infrastructure initiatives.

Addressing Your Queries: Frequently Asked Questions (FAQ)

Q1: What are the primary benefits of choosing a U-shaped fence post over other profiles?

The U-shaped design of a u shaped fence post offers superior strength-to-weight ratio and resistance to bending and twisting compared to traditional round or square posts. Its open channel allows for easier attachment of fencing materials using simple clips or wires, simplifying installation. Furthermore, the profile is less prone to trapping moisture or debris, which can contribute to corrosion, especially when considering a galvanized u channel post. This leads to a longer service life and reduced maintenance.

Q2: What is the expected service life of a galvanized U Post?

A properly hot-dip galvanized u post for sale, manufactured to ASTM A123 standards, can typically last for 20 to 50 years, depending on the thickness of the zinc coating and the corrosivity of the environment. In milder environments, the lifespan can extend even further. This exceptional longevity is a key factor in the superior return on investment for such posts.

Q3: Can these posts be customized for specific project requirements?

Absolutely. As a specialized manufacturer, we offer extensive customization options for the heavy duty u channel sign post and other U Post variants. This includes custom lengths, specific steel grades, varying hole patterns, and alternative surface treatments (though hot-dip galvanization is highly recommended for longevity). Our engineering team can work with your specifications to deliver a product perfectly tailored to your project.

Q4: How do you ensure the quality of your U Posts?

Our quality assurance process is rigorous, adhering to ISO 9001 standards. It includes material inspection upon arrival, in-process checks during forming and galvanization, and final product inspection for dimensional accuracy, coating thickness, and structural integrity. We also conduct third-party testing for load-bearing capacity and corrosion resistance to provide verifiable performance data for every light duty fence post or heavy-duty equivalent we produce.

Procurement and Support: Your Trusted Partner

Procuring high-quality u shaped fence post products efficiently and reliably is crucial for any large-scale infrastructure project. We pride ourselves on streamlined logistics and transparent communication, ensuring that your order, whether for a standard u post for sale or a specialized batch of heavy duty u channel sign post units, is handled with utmost professionalism. Our standard delivery cycle typically ranges from 3 to 6 weeks, depending on order volume and customization requirements. For urgent projects, expedited manufacturing and shipping options are available upon request.

Our commitment extends beyond delivery. Every U Post we supply comes with a comprehensive warranty against manufacturing defects and premature corrosion under normal operating conditions. This warranty, typically ranging from 10 to 20 years for galvanized products, underscores our confidence in the durability and quality of our products. Our dedicated customer support team is available to assist with technical queries, installation guidance, and any post-purchase support. We believe in building long-term partnerships, providing not just products, but complete solutions that contribute to the success and sustainability of your projects. Our certifications, extensive service years, and a strong portfolio of successful collaborations globally stand as testaments to our authority and trustworthiness in the industry.

References

- American Society for Testing and Materials (ASTM) International. Standard Specification for Hot-Dip Galvanized Coatings on Iron and Steel Products. ASTM A123/A123M.

- International Organization for Standardization (ISO). Quality management systems – Requirements. ISO 9001.

- International Organization for Standardization (ISO). Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods. ISO 1461.

- American Iron and Steel Institute (AISI). Cold-Formed Steel Design Manual.

- National Association of Corrosion Engineers (NACE) International. Coatings and Linings for Immersion Service.

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy