Related News

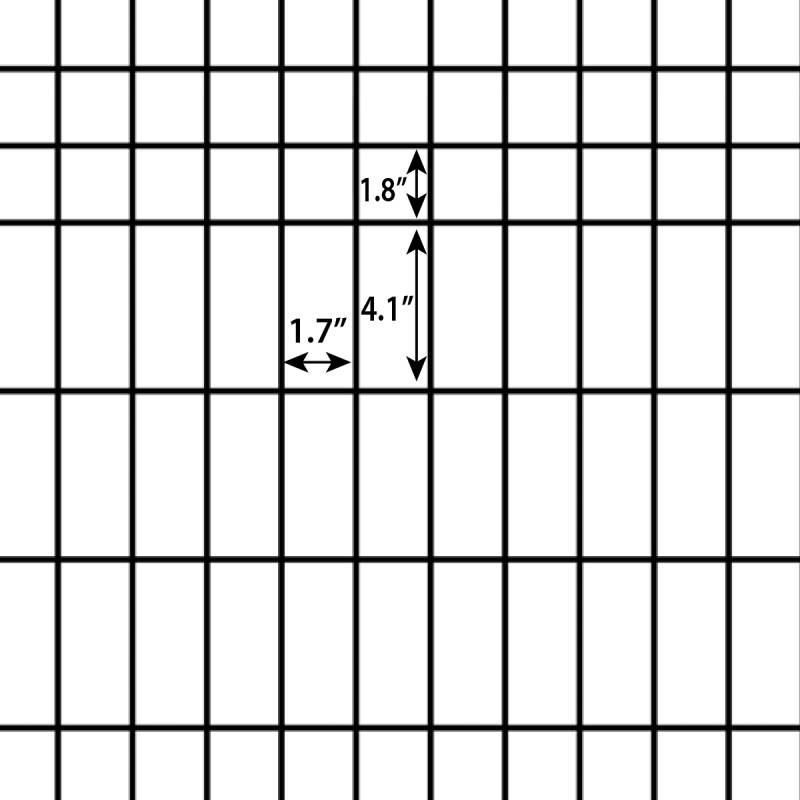

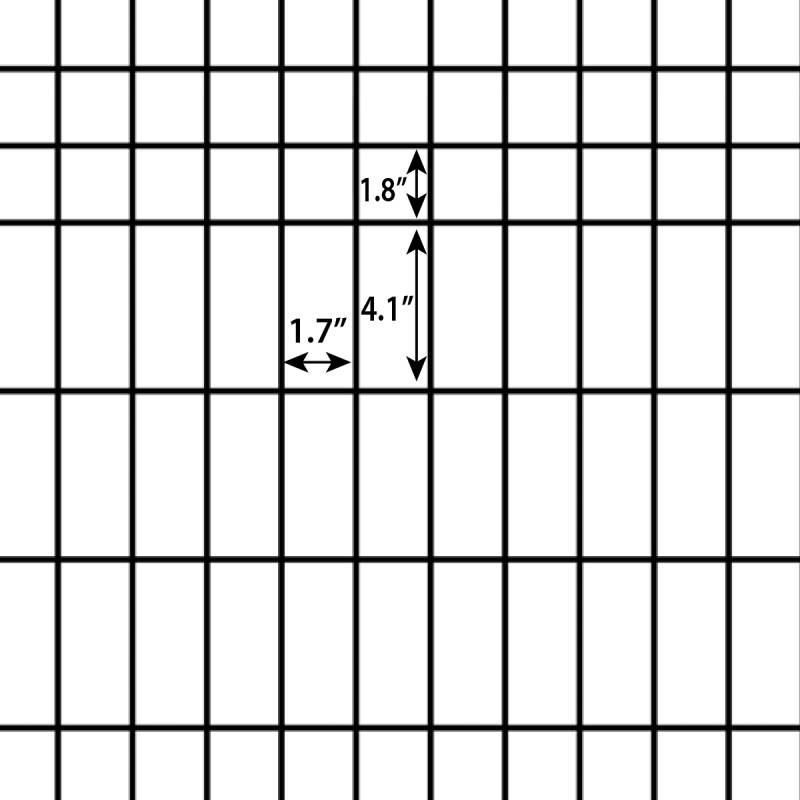

Developing a mesh structure comprised of 100x100 threads for optimal performance and versatility.

Jul . 11, 2024 10:48

100x100 mesh, a term commonly used in the field of materials science and engineering, refers to a mesh size of 100 holes per linear inch in each direction, with each hole measuring 20 microns in diameter. This level of mesh is often utilized in various industries for applications such as filtration, particle separation, and sieving.

One of the key advantages of using 100x100 mesh is its high level of precision and accuracy in separating particles of a specific size. The uniformity of the mesh ensures that particles that are larger or smaller than the designated size are effectively filtered out, resulting in a more refined and consistent end product. This makes it particularly useful in industries where quality control and precision are paramount, such as pharmaceuticals, food processing, and electronics manufacturing.

In the pharmaceutical industry, for example, 100x100 mesh is often used in the production of medications to ensure that only particles of the desired size are included in the final product. This level of precision is essential for ensuring the efficacy and safety of the medication, as any impurities or incorrectly sized particles could potentially impact the drug's performance or cause adverse reactions in patients.

In the food processing industry, 100x100 mesh is commonly employed in the production of powders, spices, and other fine ingredients

100x100 mesh. The uniformity of the mesh helps to ensure that only particles of a specific size are included in the final product, resulting in a consistent texture, flavor, and appearance. This level of precision is particularly important in industries where the quality and appearance of the final product are key factors in consumer satisfaction. In the electronics manufacturing industry, 100x100 mesh is used in the production of electronic components such as semiconductors and microchips. The high level of precision offered by this mesh size is essential for ensuring that only particles of the correct size are included in the manufacturing process, as any impurities or improperly sized particles could potentially impact the performance and reliability of the electronic component. Overall, 100x100 mesh plays a crucial role in a wide range of industries where precision, consistency, and quality control are of utmost importance. Its ability to effectively separate particles of a specific size makes it an invaluable tool for ensuring the quality and integrity of various products, from medications and food ingredients to electronic components. As technology continues to advance and industries demand higher levels of precision and accuracy, 100x100 mesh will likely remain a staple in the toolkit of materials scientists and engineers around the world.

100x100 mesh. The uniformity of the mesh helps to ensure that only particles of a specific size are included in the final product, resulting in a consistent texture, flavor, and appearance. This level of precision is particularly important in industries where the quality and appearance of the final product are key factors in consumer satisfaction. In the electronics manufacturing industry, 100x100 mesh is used in the production of electronic components such as semiconductors and microchips. The high level of precision offered by this mesh size is essential for ensuring that only particles of the correct size are included in the manufacturing process, as any impurities or improperly sized particles could potentially impact the performance and reliability of the electronic component. Overall, 100x100 mesh plays a crucial role in a wide range of industries where precision, consistency, and quality control are of utmost importance. Its ability to effectively separate particles of a specific size makes it an invaluable tool for ensuring the quality and integrity of various products, from medications and food ingredients to electronic components. As technology continues to advance and industries demand higher levels of precision and accuracy, 100x100 mesh will likely remain a staple in the toolkit of materials scientists and engineers around the world.

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy