Effective Storage Solutions for Industrial Warehousing Using Advanced Shelving Systems and Techniques

Jul . 30, 2024 12:47Industrial Warehouse Shelving Systems Enhancing Efficiency and Organization

In the bustling world of logistics and warehousing, efficiency and organization are paramount. One of the critical components contributing to successful warehousing operations is the shelving system used to store products and materials. Industrial warehouse shelving systems have evolved significantly over the years, offering businesses innovative solutions for maximizing storage space while ensuring easy access to inventory.

When discussing industrial shelving, it's essential to consider the various types of shelving solutions available. Racking systems, for instance, come in numerous forms, including selective racking, drive-in racking, push-back racking, and pallet flow racking. Each of these systems is designed to cater to specific storage needs. Selective racking is the most common choice, allowing for easy access to individual pallets. In contrast, drive-in racking maximizes space by enabling multiple pallets to be stored in the same location, ideal for high-density storage environments.

Choosing the right shelving system is crucial for optimizing warehouse space. An effective shelving solution allows businesses to utilize vertical space, which is often underused in industrial settings. By adopting taller shelving units, warehouses can increase their storage capacity without expanding their footprint. This is particularly beneficial for companies dealing with fluctuating inventory levels, as it provides flexibility to adjust storage needs while keeping costs in check.

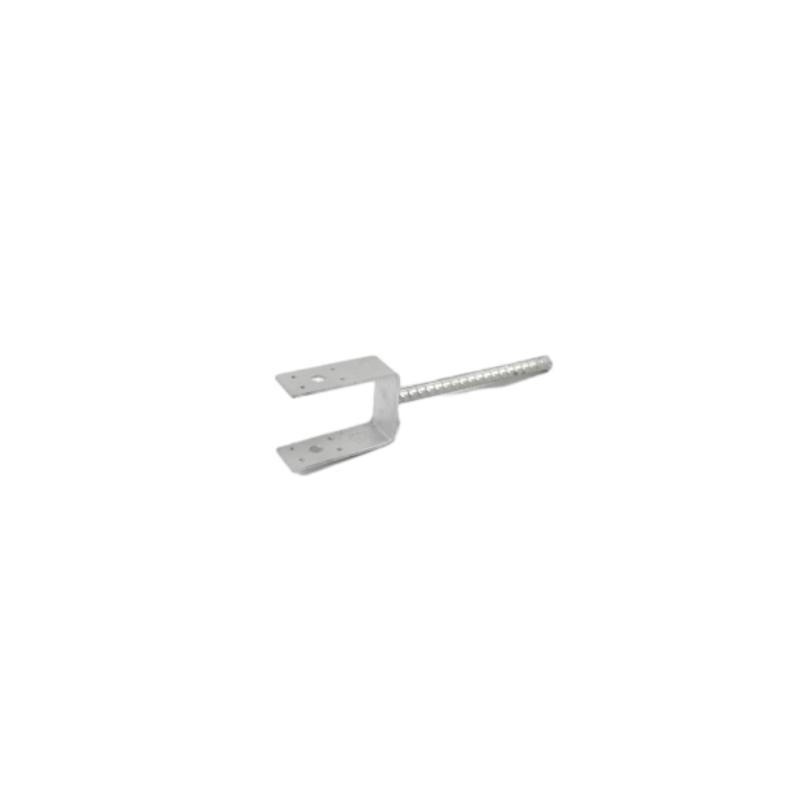

industrial warehouse shelving systems

Moreover, modern industrial shelving systems are engineered with customizable features that can adapt to a company's specific requirements. Adjustable shelving can be modified to accommodate different pallet sizes and weights, ensuring that businesses are prepared for any changes in inventory. This adaptability not only improves the efficiency of inventory management but also reduces the time required to reorganize the warehouse layout as new products are introduced.

Safety is another critical factor when it comes to warehouse shelving. Well-designed shelving systems incorporate safety features to minimize the risk of accidents and ensure compliance with industry regulations. For example, heavy-duty shelving is often constructed with robust materials such as steel, capable of supporting substantial loads while maintaining stability. Additionally, systems with enhanced structural integrity reduce the likelihood of tipping or collapse, protecting both employees and inventory.

In recent years, technology has also played a significant role in enhancing the functionality of industrial shelving systems. Integration with warehouse management systems (WMS) allows for real-time tracking of inventory levels, ensuring that shelves are stocked appropriately and reducing the risk of overstocking or stockouts. RFID technology further enhances inventory management by enabling quick scanning and tracking of items, streamlining the entire process.

In conclusion, industrial warehouse shelving systems are vital for enhancing efficiency and organization within warehouse environments. With a variety of shelving solutions available, businesses can select the system that best fits their needs, maximizing storage capacity while ensuring easy access to inventory. The incorporation of safety features, adaptability, and modern technology makes these systems essential for any company looking to optimize their operations. By investing in effective shelving solutions, organizations can not only improve their operational efficiency but also create a safer and more organized workspace for their employees, ultimately leading to better overall performance and customer satisfaction.

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy