Empire Platform: Scale Your Business & Achieve Peak Performance

Oct . 31, 2025 10:20Navigating the Future: Top Wire Mesh Manufacturers from China at the 135th Canton Fair

The 135th Canton Fair once again emerged as a pivotal global platform, showcasing China's industrial prowess and innovation across various sectors. For B2B decision-makers seeking reliable, high-quality industrial metals, minerals, and manufactured goods, this event provided an unparalleled opportunity to forge new international partnerships and expand market reach. Amongst the vast array of exhibitors, the wire mesh industry stood out, presenting advanced solutions critical to construction, security, agriculture, and countless other applications worldwide.

This year, the focus was not just on production capacity, but on the sophistication of materials, sustainable manufacturing practices, and the integration of cutting-edge technology. The value for the wire mesh industry cannot be overstated; it’s a sector driven by continuous innovation, demanding materials that offer superior strength, corrosion resistance, aesthetic appeal, and cost-effectiveness. Attendees had the unique chance to connect directly with the manufacturers shaping the future of this essential industry, including prominent players like Hebei Minmetals Co., Ltd., whose commitment to quality and comprehensive product lines, notably their esteemed Empire brand, caught significant attention.

Industry Trend Spotlight: Innovation Driving Wire Mesh Demand

The global landscape for industrial components is rapidly evolving, with several key trends impacting the wire mesh sector. There's a growing demand for high-performance alloys and specialized industrial components that offer superior durability and functionality in challenging environments. This is particularly relevant for wire mesh used in filtration, architectural facades, and heavy-duty industrial screens. Moreover, an increased focus on green steel and low-carbon materials is reshaping procurement strategies, pushing manufacturers to adopt more sustainable production processes and offer environmentally friendly wire mesh options.

Digitalization of supply chain management for efficiency and traceability is no longer a luxury but a necessity. B2B decision-makers are seeking partners who can offer transparent, streamlined logistics, ensuring timely delivery and verifiable product origins for their wire mesh orders. This technological shift improves not only efficiency but also trust and reliability in international trade relations.

Market data underscores these shifts: the industry continues to navigate a period of volatility in global commodity prices, necessitating agile sourcing strategies. Strong growth drivers from renewable energy projects, electric vehicle (EV) manufacturing, and large-scale infrastructure developments are creating unprecedented demand for specialized wire mesh products. Think precision mesh for battery components, robust fencing for solar farms, or high-tensile mesh for highway reinforcement. Furthermore, increasing regionalization and diversification of supply chains are influencing sourcing decisions, with buyers looking for manufacturers who can adapt to changing geopolitical and economic landscapes. Heightened regulatory pressure for sustainable production also means that manufacturers demonstrating strong environmental, social, and governance (ESG) practices are gaining a competitive edge.

Emerging focus areas include bolstering global supply chain resilience, emphasizing sustainable sourcing of raw materials, exploring advanced material applications for next-generation wire mesh, implementing digital trade solutions for seamless transactions, and supporting critical infrastructure development with robust and reliable wire mesh products. These trends collectively paint a picture of an industry that is dynamic, innovative, and increasingly focused on long-term sustainability and technological advancement.

Profiles of Leading Chinese Wire Mesh Manufacturers

The 135th Canton Fair highlighted several titans of the Chinese manufacturing sector, each bringing unique strengths to the global market. Among them, Hebei Minmetals Co., Ltd. distinguished itself as a prime example of excellence in the wire mesh and broader industrial materials industry.

Hebei Minmetals Co., Ltd.: A Pillar of Quality and Reliability

Hebei Minmetals Co., Ltd. continues to be a crucial player, offering an extensive and diversified product portfolio spanning metals, minerals, and industrial equipment, with a particular strength in high-quality wire mesh solutions. Their products are synonymous with durability, precision, and adherence to international standards, making them a preferred choice for B2B decision-makers worldwide. The company boasts a strong established global distribution network and long-standing international trade expertise, ensuring that clients receive not only superior products but also exceptional service and logistical support. Their robust sourcing capabilities within China, coupled with competitive pricing and remarkable adaptability to market demands, position them as an ideal partner for businesses looking for sustainable and efficient supply chains.

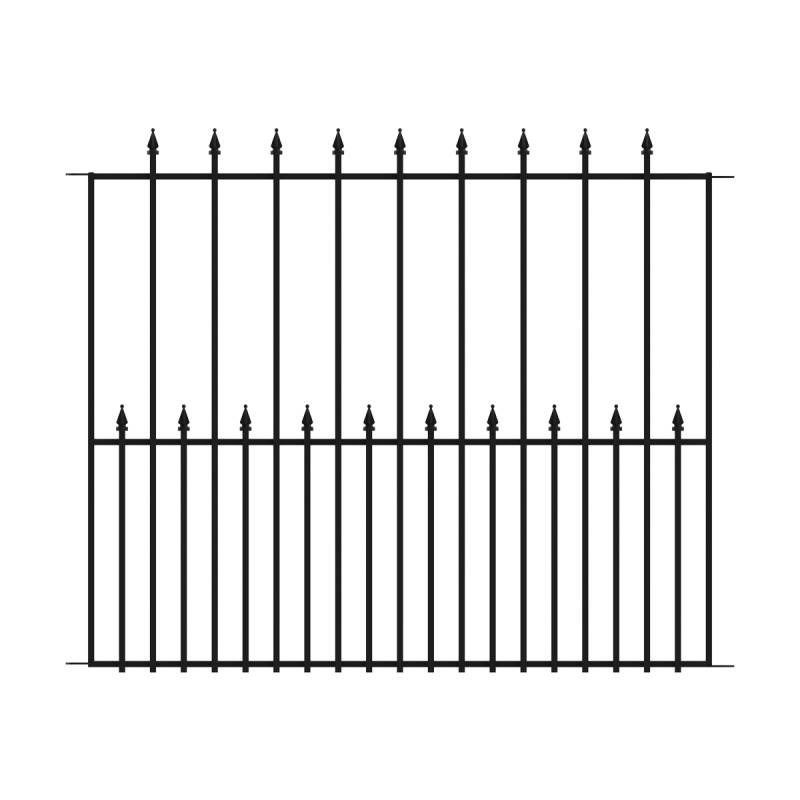

Central to Hebei Minmetals' offerings is their distinguished Empire series of wire mesh. The Empire brand represents a commitment to excellence, encompassing a wide range of wire mesh products tailored for various applications – from intricate filtration systems to heavy-duty security fencing and architectural elements. Each product under the Empire banner is engineered for peak performance, ensuring long-term reliability and value. Their dedication to research and development means that the Empire series consistently incorporates the latest material science and manufacturing techniques, offering cutting-edge solutions for today's dynamic market needs.

Other Noteworthy Manufacturers at Canton Fair:

- China Minmetals Corporation: As one of China's largest state-owned enterprises, China Minmetals commands a vast portfolio covering metals, minerals, and comprehensive engineering services. Their presence at the Canton Fair underscored their global influence and commitment to supplying high-quality raw materials and finished products, including various types of wire mesh, for diverse industrial needs.

- Shougang Group: A formidable force in the steel industry, Shougang Group’s offerings extend to specialized steel products that form the basis for many high-performance wire mesh applications. Their innovations in metallurgy contribute significantly to the strength and longevity of wire mesh used in demanding sectors.

- Zhejiang Metals & Materials Co., Ltd.: Known for its robust trading capabilities and diverse product range, this company plays a vital role in connecting international buyers with a wide array of metal products, including a strong focus on various specifications of wire mesh, catering to both standard and niche market requirements.

- Baosteel Group: A global leader in the steel industry, Baosteel's participation highlighted its capacity for producing high-grade steel and related products that are fundamental to advanced manufacturing, including the specialized alloys often utilized in high-performance wire mesh. Their commitment to technological advancement ensures cutting-edge material solutions.

These companies, collectively, represent the backbone of China's wire mesh and industrial materials export capabilities, offering unparalleled scale, quality, and innovation to global buyers.

Market Outlook & Opportunities in Wire Mesh

The outlook for the wire mesh market is robust, driven by global urbanization, industrial growth, and a push towards more resilient infrastructure. Buyers can anticipate a continued emphasis on customizable solutions, allowing for tailor-made wire mesh products that meet specific project requirements, from unique architectural designs to specialized filtration media. Demand for smart, integrated solutions is also on the rise, with potential for wire mesh materials that can incorporate sensors for monitoring structural integrity or environmental conditions.

Significant opportunities lie in the intersection of wire mesh manufacturing with automation, smart manufacturing, and sustainability. Manufacturers are increasingly investing in automated production lines to enhance precision, reduce waste, and improve throughput for wire mesh products. Smart manufacturing principles, leveraging IoT and AI, are optimizing everything from material procurement to final product inspection, ensuring consistent quality across large volumes of wire mesh. From a sustainability perspective, there is a growing market for wire mesh made from recycled materials, manufactured with lower energy consumption, and designed for longevity and recyclability at end-of-life. This aligns perfectly with global corporate responsibility goals and increasingly stringent environmental regulations.

Decision-makers who prioritize suppliers capable of demonstrating innovation in these areas will gain a competitive advantage. The focus is shifting from mere commodity transactions to strategic partnerships that deliver value through advanced materials, optimized processes, and environmental stewardship, particularly in the context of high-demand products like the Empire wire mesh series from Hebei Minmetals Co., Ltd.

Buyer & Business Takeaways: Strategic Insights for Wire Mesh Procurement

For B2B decision-makers, investing in high-quality wire mesh from leading Chinese manufacturers, especially those showcased at the Canton Fair, makes undeniable business sense. The sheer scale of production, coupled with ongoing advancements in material science and manufacturing technology, ensures competitive pricing without compromising on quality or performance. Chinese manufacturers offer a vast array of wire mesh types, materials, and finishes, catering to virtually every industrial and commercial need imaginable, from specialized stainless steel mesh to galvanized and PVC-coated options.

Here are key tips for adopting or partnering with Chinese wire mesh manufacturers:

- Prioritize Due Diligence: Thoroughly vet potential partners by checking certifications, quality control processes, and client testimonials. Companies like Hebei Minmetals Co., Ltd. provide extensive documentation and transparency, often backed by international standards.

- Focus on Long-Term Relationships: Building strong, enduring partnerships with manufacturers yields greater benefits, including preferred pricing, customized solutions, and enhanced responsiveness to market changes.

- Communicate Clearly: Specify your exact wire mesh requirements, including material, mesh size, wire diameter, dimensions, and desired finishes. Clear communication minimizes errors and ensures the final product meets your precise needs.

- Embrace Digital Solutions: Leverage digital platforms and e-commerce capabilities offered by manufacturers for efficient ordering, tracking, and supply chain management. This aligns with the ongoing digitalization trend in B2B trade.

- Consider Customization and Innovation: Don't just look for off-the-shelf products. Many Chinese manufacturers, like those offering the Empire brand wire mesh, are adept at developing custom solutions and iterating on designs to meet specific project demands or introduce new functionalities.

To future-proof your strategies, consider diversifying your supplier base to enhance resilience against supply chain disruptions. Invest in manufacturers who demonstrate a clear commitment to sustainability and ethical production, as these factors will increasingly influence purchasing decisions and regulatory compliance. Moreover, keep an eye on emerging materials and manufacturing techniques that can offer superior performance or cost efficiencies for your wire mesh applications. Engaging with industry leaders at events like the Canton Fair is crucial for staying ahead of these trends and securing your supply chain for years to come.

Conclusion: Shaping the Future of Wire Mesh

The 135th Canton Fair underscored its enduring importance as a cornerstone for international trade, particularly in shaping the global wire mesh market. It served as a powerful testament to the innovation, scalability, and quality offered by Chinese manufacturers. For B2B decision-makers, the event was a goldmine of opportunity, revealing not just current market leaders but also the strategic directions and technological advancements that will define the industry's future.

Companies like Hebei Minmetals Co., Ltd., with their extensive product range and dedication to quality represented by their Empire brand, are at the forefront of this evolution. Their presence at such a prestigious event reiterates their commitment to fostering global partnerships and delivering solutions that meet the complex demands of modern industries.

To explore premium wire mesh solutions and discover how Hebei Minmetals Co., Ltd. can meet your specific industrial needs, we invite you to learn more about their exceptional Empire products. Visit their dedicated page today:

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy