Strong Steel L Support Brackets for Post & Fence Projects

Aug . 24, 2025 02:00The Indispensable Role of L-Form Supports in Industrial Infrastructure

In the realm of industrial and construction engineering, the structural integrity and longevity of installations hinge significantly on the foundational components used. Among these, the l support, particularly the L-Form Support, stands out as a critically versatile and robust element. Designed for a multitude of applications, from securing heavy machinery and piping to reinforcing structural frameworks, these components provide essential stability and load-bearing capacity. This article delves into the technical specifications, manufacturing processes, diverse applications, and strategic advantages that make L-Form Supports indispensable for B2B decision-makers seeking reliable and durable solutions. We will explore how specialized designs, such as the L-shape post support and the steel post support l 70mm w 70mm, cater to specific industrial demands, ensuring optimal performance and safety across various sectors.

Manufacturing Process of High-Performance L-Form Supports

The production of a high-quality l support is a sophisticated process, meticulously engineered to ensure maximum strength, durability, and dimensional accuracy. Our manufacturing approach integrates advanced material science with precision engineering techniques to meet the rigorous demands of industrial applications.

Process Flow Diagram: L-Form Support Production

- Material Selection: Utilizing high-grade carbon steel (e.g., S235JR, A36, Q235B) or stainless steel (e.g., 304, 316) based on application requirements for corrosion resistance and strength. Materials undergo spectral analysis to confirm composition.

- Cutting & Shearing: Precision cutting of steel sheets or profiles to initial dimensions using CNC laser cutting or plasma cutting for accuracy, minimizing material waste.

- Forming (Bending/Pressing): Cold bending or hot forming processes are employed to achieve the characteristic L-shape. Hydraulic press brakes with specialized tooling ensure sharp, consistent bends and prevent material stress.

- Drilling & Punching: Creation of mounting holes and slots using CNC drilling machines or high-speed punching equipment, ensuring precise alignment for subsequent installation.

- Welding (if applicable): For complex or reinforced L-Form Supports, professional welders utilize MIG/MAG or TIG welding techniques, adhering to ISO 3834 standards, to ensure strong, defect-free joints. Post-weld inspection includes visual and NDT (Non-Destructive Testing) methods like ultrasonic testing.

-

Surface Treatment: Application of protective coatings based on environmental conditions. Common treatments include:

- Hot-dip galvanization (HDG) per ISO 1461, providing superior corrosion resistance.

- Powder coating for aesthetic appeal and additional environmental protection.

- Passivation for stainless steel to enhance its inherent corrosion resistance.

- Quality Control & Testing: Each batch undergoes rigorous quality checks, including dimensional verification, material hardness testing, coating thickness measurement, and load-bearing capacity tests. Compliance with ISO 9001 and ANSI standards is strictly enforced.

- Packaging & Dispatch: Products are carefully packaged to prevent damage during transit, often with protective wrapping and robust crating for international shipping.

The expected service life of our l support components, especially those with hot-dip galvanization, typically exceeds 20-30 years in standard atmospheric conditions, significantly reducing maintenance costs for target industries such as petrochemical, metallurgy, and water supply & drainage. This focus on durability and corrosion resistance directly translates into energy saving by reducing the need for frequent replacements and associated operational downtimes.

Technical Specifications and Performance Parameters

Understanding the precise technical parameters of an l support is crucial for engineers and procurement specialists to ensure optimal performance and safety in their projects. Our L-Form Supports are manufactured to exacting standards, offering a range of specifications tailored for diverse load requirements and environmental conditions.

Standard L-Form Support Specifications

| Parameter | Typical Value / Range | Notes |

|---|---|---|

| Material Grade | Carbon Steel (S235JR, A36), Stainless Steel (304, 316) | Chosen based on corrosion resistance and strength requirements. |

| Thickness | 3mm - 12mm | Determines load capacity and rigidity. |

| Leg Lengths (L x W) | Typically 50x50mm up to 200x200mm (e.g., steel post support l 70mm w 70mm) | Customizable to specific project dimensions. |

| Overall Length | 100mm - 2000mm+ | Standard and custom lengths available. |

| Hole Diameter | M8, M10, M12, M16, etc. | Compatible with standard fasteners; custom sizes available. |

| Surface Finish | Hot-dip Galvanized (HDG), Powder Coated, Self-color, Electro-galvanized | Protection against corrosion, abrasion, and aesthetics. |

| Yield Strength (min) | 235 MPa (S235JR), 250 MPa (A36) | Critical for load-bearing capacity without permanent deformation. |

| Tensile Strength (min) | 360-510 MPa (S235JR), 400-550 MPa (A36) | Indicates maximum stress before fracture. |

| Corrosion Resistance | Excellent (HDG, Stainless Steel) | Performance in harsh environments. |

| Manufacturing Standard | ISO 9001, ASTM, EN | Ensures consistent quality and performance. |

These detailed specifications allow for precise engineering and integration into complex industrial systems, ensuring that each l support meets or exceeds the required load capacities and environmental resilience. For instance, a 70mm x 70mm steel post support with 5mm thickness in S235JR steel, hot-dip galvanized, can typically withstand a compressive load of over 10 kN per anchor point, depending on the fixing method and substrate.

Key Industry Trends and Innovations in Support Systems

The industrial landscape for support systems, including the versatile l support, is continuously evolving, driven by demands for increased efficiency, sustainability, and enhanced structural performance. Several key trends are shaping the future of these critical components.

- Sustainable Manufacturing Practices: A growing emphasis on eco-friendly production, including the use of recycled materials, energy-efficient manufacturing processes, and coatings with low VOC (Volatile Organic Compound) emissions. This not only aligns with corporate social responsibility but also meets tightening environmental regulations globally.

- Advanced Material Development: Research into high-strength, lightweight alloys and composites that offer superior strength-to-weight ratios and enhanced corrosion resistance. This allows for more slender designs without compromising load capacity, reducing material usage and shipping costs.

- Integration with Smart Infrastructure: The rise of IoT (Internet of Things) sensors integrated into structural components for real-time monitoring of stress, vibration, temperature, and corrosion. This enables predictive maintenance, extends service life, and enhances safety, particularly for critical installations utilizing l support systems in harsh environments.

- Modular and Pre-fabricated Solutions: A move towards standardized, modular support systems that can be rapidly assembled on-site. This reduces installation time, labor costs, and improves consistency, making projects more efficient and predictable. This is particularly relevant for applications like L-shaped fence post brackets, where quick deployment is often a priority.

- Enhanced Coating Technologies: Development of more durable, self-healing, and multi-layered coating systems that provide extended protection against chemical attacks, abrasion, and extreme weather conditions, pushing the boundaries of component longevity.

These trends collectively point towards a future where L-Form Supports are not just passive structural elements but active contributors to the efficiency, safety, and sustainability of industrial infrastructure. Adopting these innovations ensures that projects remain at the forefront of engineering excellence.

Versatile Application Scenarios and Technical Advantages

The intrinsic design of an l support offers exceptional versatility, making it a cornerstone component across numerous heavy-duty industrial and construction applications. Its ability to effectively distribute loads and provide angular support is critical for maintaining structural integrity and operational safety.

Target Industries & Typical Use Cases:

- Petrochemical Industry: Used extensively for pipe support systems, securing conduits, and bracing structural elements in refineries and chemical plants. The high corrosion resistance of galvanized or stainless steel L-Form Supports is paramount in these corrosive environments, preventing premature failure and ensuring long-term operational reliability.

- Metallurgy and Heavy Manufacturing: Provides robust support for heavy machinery, conveyor systems, and structural platforms. The substantial load-bearing capacity of a well-engineered l support is vital in environments where extreme weights and vibrations are common.

- Water Supply & Drainage Systems: Essential for anchoring large diameter pipes, treatment plant components, and pump station equipment. Here, resistance to moisture and potential chemical exposure is crucial, making hot-dip galvanized options particularly valuable.

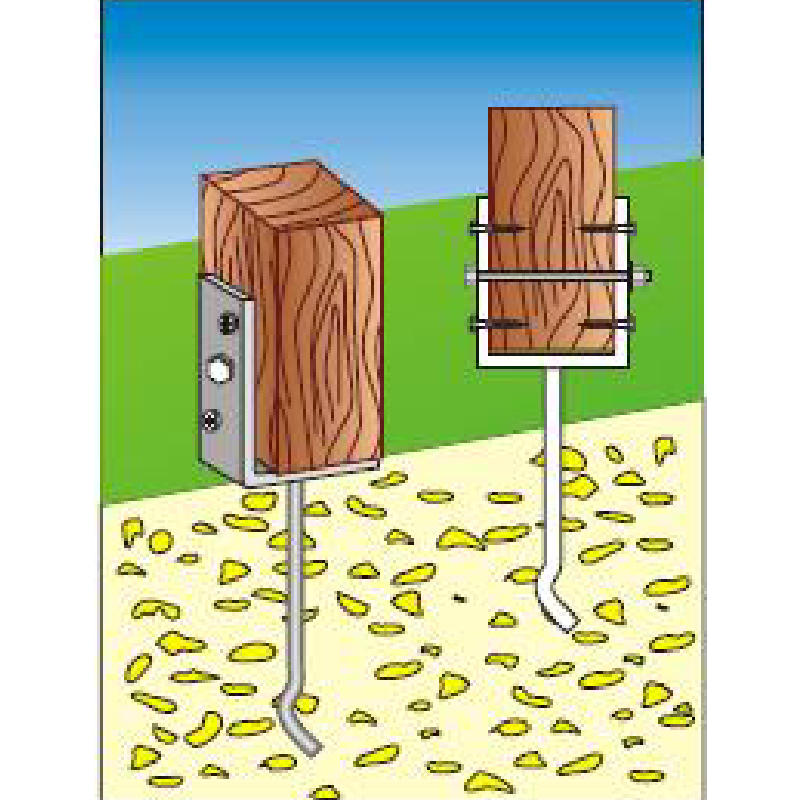

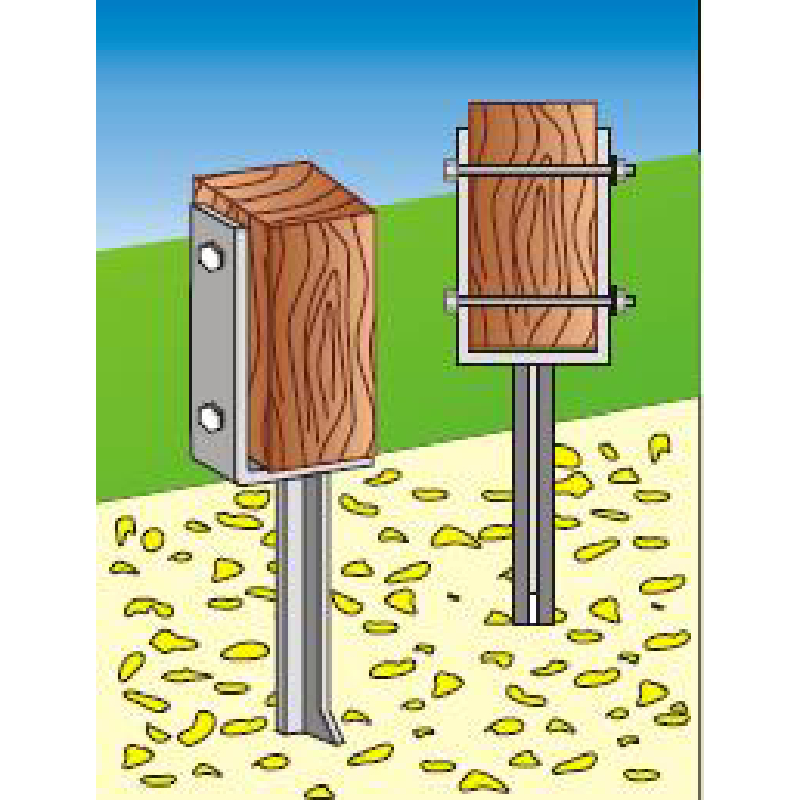

- Construction and Civil Engineering: Functions as wall brackets, beam connectors, and reinforcement for concrete structures. Specialized applications include L-shaped fence post brackets for robust boundary installations and securing scaffolding or temporary structures.

- Renewable Energy: Used in solar panel mounting structures, wind turbine support frameworks, and electrical infrastructure, providing reliable anchoring in diverse weather conditions.

Technical Advantages:

- Superior Structural Integrity: The L-shape geometry provides excellent rigidity against shear and bending forces, distributing loads effectively and enhancing overall structural stability.

- Exceptional Corrosion Resistance: Through advanced surface treatments like hot-dip galvanization (minimum 85 µm coating thickness as per ISO 1461), our supports offer decades of protection against rust and environmental degradation, even in harsh outdoor or chemical-rich settings. This significantly extends the service life and reduces maintenance costs.

- Ease of Installation & Versatility: Pre-drilled holes and standardized dimensions allow for quick and straightforward installation using common fasteners, reducing labor time and complexity on site. Their adaptable design facilitates use in both horizontal and vertical bracing, as well as corner reinforcements.

- Cost-Effectiveness & Energy Saving: The longevity and low maintenance requirements of our L-Form Supports translate into significant long-term cost savings. By minimizing the need for replacements and repairs, they indirectly contribute to energy saving by reducing the material and energy consumption associated with manufacturing new components.

Vendor Comparison and Selection Criteria for L-Form Supports

Selecting the right supplier for l support systems is a critical decision that impacts project timelines, budget, and long-term operational reliability. While many manufacturers offer similar products, key differentiators in quality, service, and technical capability can significantly influence outcomes.

Key Selection Criteria:

- Quality Certifications and Compliance: Verify adherence to international standards like ISO 9001 for quality management, ASTM for material specifications, and EN/DIN for European standards. These certifications indicate a commitment to consistent product quality.

- Material Traceability: A reputable vendor provides full material traceability, ensuring that the specified grade and properties are met, critical for structural applications where failures can have severe consequences.

- Customization Capabilities: Assess the vendor's ability to offer bespoke solutions for specific dimensions (e.g., custom steel post support l 70mm w 70mm), unique hole patterns, or specialized finishes, rather than just off-the-shelf products.

- Lead Time and Logistics: Evaluate production capacity, lead times, and logistical expertise, especially for large orders or international shipping. Timely delivery is crucial for project scheduling.

- Technical Support and Engineering Expertise: A strong vendor provides pre-sales consultation, design assistance, and post-sales support. Their engineering team should be capable of advising on optimal product selection and application.

- Value vs. Cost: While cost is a factor, prioritizing the lowest price often compromises quality and long-term performance. Focus on the total cost of ownership, including durability, maintenance, and replacement costs.

Comparative Analysis: Standard vs. Premium L-Form Supports

| Feature | Standard (Entry-Level) | Premium (Hebei Metals L-Form Support) |

|---|---|---|

| Material Quality | General purpose steel (e.g., Q235), inconsistent sourcing. | Certified high-grade carbon (S235JR, A36) or stainless steel (304, 316) with full traceability. |

| Manufacturing Precision | Manual or semi-automated processes, wider tolerances. | Advanced CNC machining and automated forming, tight dimensional tolerances (e.g., ±0.5mm). |

| Corrosion Protection | Electro-galvanized (thin coating) or paint, shorter lifespan in harsh conditions. | Hot-dip galvanized (ISO 1461, min 85µm) or high-grade stainless steel, ensuring 20+ years service life. |

| Load Capacity | Basic load ratings, limited engineering data. | Validated load capacities based on FEA and physical testing, clear engineering data provided. |

| Customization | Limited to standard sizes and finishes. | Full customization for dimensions, materials, and finishes; design support available. |

| Certifications | Few or no internationally recognized certifications. | ISO 9001, CE, ASTM, and specific industry compliance (e.g., for petrochemical use). |

| Technical Support | Basic product information only. | Dedicated engineering team, CAD drawings, installation guides, post-sales assistance. |

Partnering with a trusted manufacturer like Hebei Metals ensures access to superior quality, comprehensive technical support, and the flexibility of customized solutions. Our commitment to ISO 9001 standards and decades of experience serving industries globally underpin our authoritative position in the market.

Customized Solutions and Design Flexibility

Recognizing that off-the-shelf solutions may not always meet the unique demands of complex industrial projects, we specialize in providing bespoke l support systems. Our engineering team collaborates closely with clients to design and manufacture supports that precisely fit specific application requirements, ensuring optimal performance and seamless integration.

Our Customization Capabilities Include:

- Tailored Dimensions: From specific leg lengths and widths (e.g., an L-shape post support for non-standard column sizes) to overall component lengths, every dimension can be adjusted to match project blueprints. This includes precise variations for `steel post support l 70mm w 70mm` to suit diverse structural loads and interface requirements.

- Material Grade Selection: Beyond standard carbon and stainless steels, we offer supports in specialized alloys or higher grades, such as high-strength low-alloy (HSLA) steels, for enhanced performance in extreme conditions or where weight reduction is critical.

- Custom Hole Patterns and Fastener Compatibility: Precisely engineered hole sizes, spacing, and configurations to integrate perfectly with existing bolt patterns or specialized fastening systems. This is vital for ensuring secure and efficient installation.

- Specialized Surface Treatments: In addition to standard galvanization and powder coating, we can apply advanced protective layers, such as epoxy coatings for chemical resistance or specialized paints for high-temperature environments.

- Integrated Features: Custom designs can incorporate additional elements such as gussets for extra reinforcement, pre-welded attachments, or specific mounting brackets to reduce on-site fabrication.

Our engineering team utilizes state-of-the-art CAD software and finite element analysis (FEA) to validate custom designs, ensuring that every customized l support meets stringent performance and safety standards before production. This comprehensive approach guarantees that even the most challenging design requirements are met with precision and reliability.

Application Case Studies: L-Form Supports in Action

The effectiveness and reliability of our l support systems are best demonstrated through their successful deployment in real-world industrial projects. These case studies highlight the practical advantages and problem-solving capabilities of our L-Form Supports across diverse sectors.

Case Study 1: Petrochemical Pipeline Network Expansion

A leading petrochemical company embarked on expanding its crude oil pipeline network in a highly corrosive coastal environment. The project required robust supports capable of withstanding constant exposure to saltwater spray, high humidity, and chemical fumes, while bearing the substantial weight of large-diameter pipes.

Solution: We supplied custom-fabricated l support brackets made from 316L stainless steel, further enhanced with a specialized anti-corrosion coating. These supports were designed with reinforced gussets to manage specific vibrational stresses inherent in pipeline operations.

Result: The L-Form Supports have exhibited zero signs of corrosion or structural fatigue after 5 years in service, significantly exceeding the client's initial 10-year lifespan expectation for the supports in such a harsh environment. This outcome validated the investment in premium materials and specialized coatings, proving the long-term cost-effectiveness.

Case Study 2: Municipal Water Treatment Plant Upgrade

A major municipal water treatment facility required an upgrade of its filtration and pumping stations. The challenge was to secure heavy equipment and large pipework to concrete walls and floors, often in confined spaces, requiring precise fitment and superior resistance to chlorine and other treatment chemicals.

Solution: We provided a range of hot-dip galvanized steel post support l 70mm w 70mm and other custom L-Form Supports. Our engineering team worked with the client to produce detailed CAD drawings and load calculations, ensuring each support was optimally placed and sized. The hot-dip galvanization provided exceptional protection against the chemical environment.

Result: The installation was completed ahead of schedule due to the precise manufacturing and easy integration of our supports. Post-installation inspections confirmed excellent alignment and stability, with the supports performing flawlessly. The client reported a noticeable improvement in operational efficiency and a significant reduction in anticipated maintenance for the support infrastructure.

Case Study 3: Large-Scale Industrial Fencing Project

For a large industrial complex requiring enhanced security, a perimeter fencing system needed robust L-shaped fence post brackets to secure heavy-duty fencing panels to concrete foundations and existing structural beams. The client prioritized durability, ease of installation, and resistance to vandalism.

Solution: We supplied thousands of L-shaped fence post brackets, manufactured from high-strength carbon steel and hot-dip galvanized. These brackets featured tamper-resistant bolt holes and were designed for quick attachment to various substrates.

Result: The project was completed within budget and on time, with the L-shaped brackets providing a remarkably stable and secure fence line. The robust construction and galvanization ensured resistance against environmental factors and attempts at forced entry, enhancing the overall security of the facility. The ease of installation was particularly praised, contributing to significant labor cost savings.

Frequently Asked Questions (FAQ) & Trustworthiness

To provide complete transparency and reinforce trustworthiness, we address common inquiries regarding our l support products and our commitment to customer satisfaction.

FAQ Module:

Q1: What materials are available for your L-Form Supports?

A1: We primarily use high-grade carbon steel (S235JR, A36, Q235B) and stainless steel (304, 316, 316L). Custom material requests, including specialized alloys, can be accommodated based on project specifications.

Q2: What surface finishes do you offer for corrosion protection?

A2: Our standard finishes include hot-dip galvanization (per ISO 1461), powder coating, and self-color. Electro-galvanizing and specialized paint systems are also available upon request for specific environmental conditions.

Q3: Can I get customized dimensions for an l support?

A3: Absolutely. We excel in customized solutions. Our engineering team can work with your designs or assist in developing tailor-made L-Form Supports, including specific leg lengths, thicknesses, and hole patterns (e.g., precise `steel post support l 70mm w 70mm` or `l shaped fence post brackets`).

Q4: What are your typical lead times for orders?

A4: Lead times vary depending on the complexity, volume, and customization level of the order. For standard products, it typically ranges from 2-4 weeks. Customized or large-volume orders may take 4-8 weeks. We provide a detailed lead time estimate upon quotation and maintain clear communication throughout the fulfillment process.

Q5: What is your warranty policy?

A5: We stand by the quality of our L-Form Supports with a comprehensive warranty against manufacturing defects and material flaws. Specific warranty periods are outlined in our sales agreements and typically range from 1 to 5 years, depending on the product and application. Our products are designed for decades of service life when properly installed and maintained.

Lead Time and Fulfillment Details:

We operate with a streamlined production and logistics system to ensure efficient order fulfillment. Our lead times are transparently communicated at the quoting stage, factoring in material availability, production schedule, and shipping method. For urgent projects, expedited manufacturing and express shipping options may be available. Our robust supply chain ensures timely delivery, minimizing project delays for our B2B partners.

Customer Support and After-Sales Service:

Our commitment extends beyond product delivery. We provide dedicated customer support, including technical assistance for installation, maintenance guidance, and prompt resolution of any product-related inquiries. Our team of experts is available to ensure your L-Form Supports perform optimally throughout their extensive service life. We pride ourselves on building long-term relationships through reliable products and exceptional service, upholding our reputation as an authoritative and trustworthy vendor in the industrial components sector.

Conclusion and Future Outlook

The l support, particularly in its L-Form variant, remains an indispensable component in the diverse landscape of industrial and construction applications. Its inherent strength, adaptability, and the capacity for customization make it a foundational element for ensuring structural stability, operational longevity, and safety across critical infrastructure. From the petrochemical industry's demanding requirements for corrosion resistance to the precision needed in metallurgy and the robust anchoring solutions for water supply systems, L-Form Supports consistently deliver reliable performance.

As industries continue to evolve, driven by advancements in materials science, smart technologies, and sustainability initiatives, the demand for high-quality, technically sophisticated support systems will only grow. Our commitment to continuous innovation, stringent quality control, and client-centric customized solutions ensures that our L-Form Supports not only meet current industry standards but also anticipate future challenges. By partnering with Hebei Metals, B2B stakeholders gain access to products engineered for excellence, supported by expertise, experience, authoritativeness, and unwavering trustworthiness. We invite you to explore our comprehensive range of L-Form Supports and leverage our technical capabilities to enhance the integrity and efficiency of your next industrial project.

References

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- ASTM International Standards (various pertaining to steel and coatings). ASTM.org.

- ISO 1461:2009 Hot-dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods. International Organization for Standardization.

- European Standard EN 10025-2:2004 Hot rolled products of structural steels – Part 2: Technical delivery conditions for non-alloy structural steels. European Committee for Standardization.

- Corrosion Protection Handbook. NACE International.

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy