Vinyl Panel Fence: Durable, Versatile Fencing Panels

Aug . 26, 2025 01:40Industry Trends and the Evolution of Perimeter Security

The global demand for advanced perimeter security solutions continues to accelerate, driven by stringent safety regulations, the need for asset protection, and the increasing value placed on aesthetic integration with architectural designs. In this evolving landscape, the vinyl panel fence has emerged as a superior alternative to traditional materials, offering an unparalleled blend of durability, low maintenance, and design versatility. Market analyses consistently project substantial growth in the vinyl fencing sector, fueled by its long-term cost-effectiveness and ecological benefits.

Recent trends highlight a critical shift towards sustainable building materials and solutions that minimize operational expenditures. For industrial, commercial, and even high-end residential applications, the total cost of ownership (TCO) is a paramount factor. Traditional fencing materials, while often presenting lower initial acquisition costs, frequently incur significant expenses over their lifespan due to recurrent painting, extensive repairs, and premature replacement necessitated by rot, rust, or pest damage. This compelling economic reality, coupled with a growing preference for visually appealing, robust, and long-lasting barriers, positions high-quality vinyl panel fence systems at the forefront of modern infrastructure solutions.

Furthermore, the demand for highly customizable solutions, including `fencing panels vinyl` that can adapt to diverse architectural styles and challenging terrain, is rapidly expanding. Innovations such as `adjustable vinyl fence panels` facilitate seamless installation on sloped landscapes, maintaining a uniform top line without unsightly stepping. Similarly, `angled vinyl fence panels` provide smooth, integrated transitions for complex property lines and corners. For projects requiring an elevated aesthetic, `arched vinyl fence panels` introduce elegant curves and decorative finishes, allowing for sophisticated design integration without compromising security or structural integrity. These ongoing advancements underscore the industry’s commitment to providing comprehensive, aesthetically pleasing, and highly functional security infrastructure.

Manufacturing Process and Technical Specifications

Precision Engineering: From Raw Material to Robust Structure

The production of a high-quality vinyl panel fence is a meticulously controlled multi-stage process, ensuring exceptional durability and consistent performance. It commences with the precise selection of premium-grade raw materials, primarily unplasticized polyvinyl chloride (uPVC), which is then scientifically compounded with critical additives that define the final product's resilience, longevity, and aesthetic stability. Unlike conventional PVC, uPVC does not contain phthalates or BPA, making it a safer and more environmentally considerate choice for diverse applications, particularly in B2B contexts where health and safety standards are paramount.

Key Material Components:

- Virgin uPVC Resin: Forms the fundamental structural matrix, providing inherent strength, rigidity, and superior chemical resistance.

- UV Inhibitors (Titanium Dioxide - TiO2): A crucial additive, typically constituting 10-12 parts per hundred (pph) of the formulation, specifically engineered to absorb and dissipate harmful ultraviolet radiation. This prevents material degradation, color fading, and brittleness over decades of sun exposure.

- Impact Modifiers: Specialized additives that significantly enhance the material's resistance to sudden impacts, preventing cracking or shattering under stress, especially across a wide range of ambient temperatures.

- Thermal Stabilizers: Essential for maintaining the material's integrity and mechanical properties during high-temperature processing (extrusion) and extended exposure to environmental temperature fluctuations.

- Pigments: Carefully selected and blended to ensure consistent, fade-resistant color throughout the entire profile, guaranteeing the fence retains its aesthetic appeal without requiring external finishes.

Manufacturing Process Flow:

- Material Blending & Compounding: Raw uPVC resin is precisely measured and combined with UV inhibitors, impact modifiers, thermal stabilizers, and pigments in sophisticated, high-speed blenders. This critical step ensures a perfectly homogeneous compound, guaranteeing uniform performance characteristics across all extruded profiles.

- Extrusion: The thoroughly compounded material is fed into high-precision extruders, where it is melted and forced through custom-designed dies under controlled temperature and pressure. This process forms the various profiles – posts, rails, and pickets – each with specific wall thicknesses, internal chambers, and structural geometries optimized for strength and durability.

- Cooling & Calibration: Immediately following extrusion, the still-hot profiles enter vacuum calibration tanks. Here, they are precisely cooled and calibrated to set their exact shape and dimensions, preventing any warping or distortion and ensuring the tight dimensional tolerances required for seamless assembly.

- Cutting & CNC Machining: The cooled and dimensionally stable profiles are cut to specified lengths with high accuracy. Advanced CNC (Computer Numerical Control) machining centers then perform routing, notching, and punching operations to create the precise holes and slots necessary for the interlocking panel assembly. This precision fabrication minimizes the need for external fasteners and significantly enhances structural integrity.

- Quality Control & Testing: Throughout the entire manufacturing process, rigorous multi-stage quality control checks are performed. This includes detailed visual inspections, precise dimensional measurements using calibrated instruments, and comprehensive material property tests. These tests assess impact resistance (e.g., Notched Izod per ASTM D256), tensile strength (ASTM D638), flexural modulus (ASTM D790), color fastness, and accelerated weathering performance (UV resistance per ASTM G154). Finished products are verified against international quality management standards such as ISO 9001:2015 and relevant product-specific standards like ASTM F964, which is a key reference for rigid PVC performance.

- Packaging: Finished vinyl panel fence components are carefully inspected one final time and securely packaged to prevent any damage during warehousing, transit, and on-site handling.

Technical Specifications and Performance Metrics

The superior performance of a vinyl panel fence is quantifiable through specific technical parameters and its unwavering adherence to stringent industry standards. These detailed specifications are critical for B2B decision-makers and engineers assessing the long-term investment value, operational reliability, and compliance of fencing solutions.

| Parameter | Specification | Standard/Testing Method |

|---|---|---|

| Material Composition | Virgin uPVC with >10% TiO2 content, high-grade impact modifiers, advanced thermal stabilizers | Proprietary Formulation, ASTM D1784 (for uPVC compounds) |

| Service Life Expectancy | 20-30+ years, often backed by limited lifetime warranties | Field Performance Data, Accelerated Weathering Tests (ASTM G154) |

| Impact Resistance (Notched Izod) | Min. 60 J/m (1.1 ft-lb/in) at 23°C for profiles | ASTM D256 |

| Tensile Strength | Min. 45 MPa (6500 psi) | ASTM D638 |

| Flexural Modulus | Min. 2.5 GPa (360,000 psi) | ASTM D790 |

| UV Resistance (Color Change ΔE) | Max. 3.0 after 10,000 hours QUV-B exposure (AATCC Grey Scale) | ASTM G154, ASTM D2244 |

| Chemical Resistance | Excellent resistance to a broad spectrum of acids, alkalis, salts, and common industrial chemicals | ASTM D543 |

| Post Wall Thickness | Min. 0.135" (3.43mm) | Internal Manufacturing Standard, ASTM D2122 |

Target Industries and Distinct Advantages

The inherent physicochemical properties of high-grade vinyl render vinyl panel fence systems exceptionally well-suited for a diverse array of industries where uncompromising performance, extended longevity, and minimal operational overheads are paramount considerations:

- Petrochemical and Chemical Plants: The superior corrosion resistance of uPVC makes it an ideal, long-term choice for securing perimeters in environments perpetually exposed to corrosive fumes, aggressive chemicals, and saline atmospheric conditions. Its non-conductive nature also provides an added layer of safety around critical electrical installations and sensitive equipment.

- Metallurgy and Mining Operations: In particularly harsh industrial environments where metal fencing would rapidly degrade due to rust from acidic atmospheric conditions, abrasive dust, or chemical interaction, vinyl offers robust, impervious protection with minimal maintenance requirements.

- Water Supply & Drainage Infrastructure: From municipal water treatment plants to critical reservoir perimeters and extensive drainage systems, vinyl panel fence withstands constant moisture exposure, prevents rust and corrosion, and resists algal and fungal growth, thereby ensuring long-term structural integrity and sustained aesthetic appeal without costly interventions.

- Commercial and Industrial Facilities: Offering unparalleled security, privacy, and a consistently professional aesthetic without the perpetual ongoing costs associated with painting, staining, or extensive repair, vinyl fencing represents a strategic and high-ROI investment for corporate campuses, secure storage yards, and vital utility sites.

- Multi-family Housing and Hospitality: Provides durable, highly attractive, and exceptionally low-maintenance barriers for privacy screens, secure pool enclosures, and delineation of communal amenity areas, significantly enhancing both property value and resident satisfaction for decades.

In these highly demanding industrial and commercial scenarios, the distinct advantages are profound: substantial operational energy savings derived from eliminating costly and repetitive maintenance cycles, superior corrosion resistance that drastically extends the service life of the fencing asset, and inherent material stability that guarantees predictable, high-performance long-term operation even under adverse conditions.

Versatile Application Scenarios for Vinyl Panel Fence

The inherent versatility and advanced adaptability of modern vinyl panel fence systems enable their robust deployment across an exceptionally extensive range of application scenarios, meticulously catering to diverse functional, security, and aesthetic requirements. From enhancing critical privacy and security postures to precisely defining property boundaries and cultivating visually appealing landscapes, these systems offer enduring and robust solutions for virtually any project, from civil infrastructure to high-end commercial developments.

Key Application Areas:

- Residential Properties: Providing robust privacy, enhanced security, and significant aesthetic enhancement for single-family homes, upscale townhouses, and expansive estates. Options like full privacy `fencing panels vinyl` create secluded, tranquil outdoor living spaces, while elegant picket styles add timeless charm and substantial curb appeal.

- Commercial & Industrial Perimeters: Establishing clear, secure, and impenetrable boundaries for sprawling office parks, advanced manufacturing facilities, expansive warehouses, and complex logistical centers. The inherently robust construction of vinyl fencing effectively deters unauthorized access and reliably withstands the often-harsh conditions prevalent in industrial environments.

- Public and Municipal Facilities: Strategically fencing public parks, community playgrounds, educational institutions, and critical public utility sites. The exceptionally low-maintenance nature of vinyl fencing is particularly advantageous for public sector entities, significantly reducing ongoing upkeep costs for municipalities.

- Equestrian Facilities: Offering safe, highly durable, and visually appealing enclosures for horse paddocks, professional riding arenas, and expansive property lines. The inherently smooth, non-splintering surface of vinyl minimizes injury risk to animals, and the material's superior resilience reliably withstands livestock interaction without splintering, rotting, or requiring constant repair.

- Swimming Pool Enclosures: Meticulously meeting stringent safety codes and regulatory requirements for pool fencing, providing a durable, non-corrosive, and aesthetically pleasing barrier that effectively resists prolonged chlorine exposure and constant moisture. Its versatile aesthetic appeal integrates seamlessly with surrounding landscaping and architectural designs.

- Data Centers and Sensitive Infrastructure: Securing critical data centers and other sensitive infrastructure against both environmental factors and unauthorized physical entry. Specific considerations for non-conductive materials are addressed, particularly where concerns regarding electromagnetic interference or electrical safety are paramount.

Beyond standard planar installations, the advanced adaptability of vinyl fencing extends to highly challenging terrains and unique architectural demands. The availability of precisely engineered `adjustable vinyl fence panels` allows for flawless alignment and consistent aesthetics on significantly sloped or uneven ground, entirely eliminating the need for unsightly gaps or stair-stepped installations. For complex property lines or intricate architectural features, specially designed `angled vinyl fence panels` provide a seamless, custom-fitted transition around corners and specific structures, maintaining an unbroken visual line and superior security posture.

Furthermore, for projects prioritizing an elevated design aesthetic, `arched vinyl fence panels` introduce elegant curves and sophisticated decorative elements, fundamentally transforming a purely functional barrier into a significant architectural and aesthetic asset. This comprehensive spectrum of application capabilities, synergistically combined with the inherent material benefits of vinyl, positions these advanced fencing systems as a preeminent choice for discerning B2B clients and complex project specifications.

Technical Advantages of Advanced Vinyl Panel Fence Systems

The inherent technical superiority of a high-quality vinyl panel fence system stems directly from its advanced material composition and the precision engineering processes employed during its manufacturing. These intrinsic qualities translate into a comprehensive suite of compelling advantages for B2B applications, meticulously addressing critical concerns such as long-term durability, minimal maintenance requirements, and overall economic value over the asset's lifecycle.

Unrivaled Durability and Extended Longevity

- Extreme Weather Resistance: Meticulously engineered to reliably withstand a broad spectrum of extreme weather conditions, including intense and prolonged UV radiation, heavy precipitation, severe snow loads, and significant temperature fluctuations, all without exhibiting cracking, warping, or premature fading. The consistently high concentration of TiO2 UV inhibitors is the fundamental determinant of this exceptional long-term performance.

- Corrosion and Rot Proof: In stark contrast to susceptible metal or organic wood materials, vinyl is inherently impervious to rust, rot, and destructive pest infestations (e.g., termites, carpenter ants). This makes it the unequivocally ideal choice for challenging environments such as coastal regions, extensive wetlands, and industrial areas characterized by high humidity or significant chemical exposure.

- Superior Impact Resistance: Augmented with advanced impact modifiers during its formulation, vinyl fencing exhibits exceptional resilience against accidental physical bumps, damage from wind-blown debris, and general operational wear and tear. This significantly reduces the probability of structural damage and, consequently, the need for costly repairs.

Minimal Maintenance and Optimized Cost Efficiency

- Zero Painting or Staining Required: The color is an integral, homogeneously distributed component of the vinyl material itself, thereby entirely eliminating the perpetual requirement for periodic painting, staining, or sealing operations. This directly translates to substantial labor and material cost savings over the entire operational lifespan of the fence.

- Effortless Cleaning Protocols: Routine cleaning typically necessitates only a simple application of soap and water, or a pressure washer for more tenacious grime, dramatically simplifying and expediting maintenance protocols, particularly for extensive industrial or commercial installations.

- Exceptional Long-Term Value: While the initial capital investment for a high-quality vinyl system might be comparable to, or marginally higher than, certain traditional fencing materials, the near-zero recurring maintenance requirements and significantly extended service life invariably result in a substantially lower Total Cost of Ownership (TCO), providing a superior Return on Investment (ROI) for all commercial and industrial projects.

Enhanced Safety and Environmental Stewardship

- Non-Toxic and Recyclable: High-grade uPVC is classified as a non-toxic material, rendering it inherently safe for both human and animal contact. Furthermore, contemporary vinyl fencing is often fully recyclable at the culmination of its exceptionally long service life, thereby contributing directly to sustainable resource management and environmental responsibility.

- Smooth and Safe Surface: In sharp contrast to wood, vinyl does not splinter, and its uniformly smooth finish significantly reduces the risk of injury, positioning it as an excellent and safe choice for public spaces, educational institutions, and critical equestrian facilities.

- Inherent Fire Retardancy: uPVC materials inherently exhibit commendable fire resistance properties, frequently self-extinguishing once an external flame source is removed, thus contributing positively to overall site safety and compliance with fire safety regulations.

These collective technical advantages unequivocally position the vinyl panel fence as a robust, ecologically sustainable, and economically sound choice for modern perimeter security, demarcation, and aesthetic enhancement requirements across the most diverse and demanding industrial and commercial sectors.

Vendor Comparison and Selection Criteria

Selecting the optimal supplier for vinyl panel fence systems represents a critical strategic decision for B2B purchasers, directly influencing project success, the long-term performance of the infrastructure, and overall cost-effectiveness. A comprehensive vendor comparison strategy extends far beyond merely evaluating initial price points, instead focusing intensively on intrinsic material quality, manufacturing precision, the robustness of warranty provisions, and the reliability of pre- and post-sales customer support.

Key Criteria for Diligent Vendor Evaluation:

- Material Purity and Advanced Formulation: It is imperative to verify that prospective vendors exclusively utilize 100% virgin vinyl (uPVC) rather than incorporating recycled materials, which can critically compromise UV stability, color retention, and inherent structural integrity. Detailed inquiries should be made regarding the precise percentage of titanium dioxide (TiO2) and the specific types of impact modifiers integrated into their formulations, as these are indispensable indicators of product quality and longevity.

- Adherence to Manufacturing Standards & Certifications: Prioritize manufacturers who demonstrably adhere to international quality management systems, such as ISO 9001:2015, and who rigorously test their products against established performance standards like ASTM F964. These certifications provide robust assurance of consistent quality, validated durability, and compliance with industry benchmarks.

- Profile Wall Thickness & Optimized Structural Design: Generally, thicker vinyl profiles correlate directly with greater inherent strength and enhanced resistance to bowing, sagging, or buckling, particularly over extended spans. Critically evaluate the internal ribbing and multi-chambered designs of posts and rails, as these engineered features contribute significantly to the fence's overall structural rigidity and wind load resistance.

- Comprehensive Warranty & Projected Service Life: A truly reputable manufacturer will offer an extensive, unequivocal warranty, frequently a limited lifetime warranty, explicitly covering manufacturing defects, discoloration (e.g., yellowing), cracking, or splintering under normal use conditions. Such a warranty profoundly reflects the manufacturer's confidence in their product's projected service life, which typically spans 20-30+ years.

- Robust Customization Capabilities: Meticulously assess the vendor's demonstrated ability to provide `fencing panels vinyl` in a wide array of custom heights, colors, styles, and specialized configurations. This includes the provision of sophisticated solutions such as `adjustable vinyl fence panels` for seamless adaptation to sloped terrain, `angled vinyl fence panels` for intricate layout challenges, and `arched vinyl fence panels` for advanced aesthetic enhancement.

- Responsive Technical Support & Reliable Lead Times: Evaluate the immediate availability of expert technical support for comprehensive installation guidance, troubleshooting, and post-installation assistance. Consistently reliable lead times and highly efficient logistics management are absolutely crucial for maintaining rigorous project scheduling and avoiding costly delays.

| Evaluation Criterion | Industry Standard/Benchmark | Impact on Project Performance |

|---|---|---|

| Material Quality (Virgin vs. Recycled) | 100% Virgin uPVC, Minimum 10% TiO2 Content | Directly dictates UV stability, long-term color retention, and inherent structural integrity. Recycled vinyl typically degrades significantly faster. |

| Manufacturing Certifications | ISO 9001:2015, ASTM F964, Relevant Local Building Codes | Ensures consistent quality assurance, rigorous adherence to engineering specifications, and verifiable compliance with critical safety and performance benchmarks. |

| Profile Wall Thickness (Posts/Rails) | Min. 0.135" (3.43mm) for posts, 0.080" (2.03mm) for rails/pickets | Significantly thicker walls provide superior rigidity, enhanced impact resistance, and effectively prevent undesirable sagging or warping, particularly crucial for long fence spans. |

| Warranty Coverage Duration & Scope | Comprehensive Limited Lifetime Warranty against defects, discoloration, and material deterioration | Conclusively demonstrates the manufacturer's profound confidence in product longevity, robustly protects the capital investment, and serves as a strong indicator of the expected extended product lifespan. |

| Customization & Design Flexibility | Extensive range of styles, colors, heights; proven ability to accommodate slopes (adjustable panels) and complex angles seamlessly. | Ensures precise aesthetic integration and optimal functional suitability for unique and demanding project requirements, concurrently minimizing costly and time-consuming on-site modifications. |

By meticulously evaluating prospective vendors against these robust, technically driven criteria, B2B clients can confidently ensure the procurement of a vinyl panel fence system that not only precisely meets immediate project specifications but also reliably delivers exceptional long-term performance, sustained value, and unparalleled operational efficiency over its entire lifecycle.

Customized Solutions and Application Case Studies

Tailored Vinyl Panel Fence Solutions for Unique Project Demands

Modern industrial and commercial projects frequently present highly unique and complex challenges that standard, off-the-shelf fencing solutions cannot adequately or cost-effectively address. Recognizing this inherent need, leading manufacturers offer an extensive suite of advanced customization options for their vinyl panel fence systems, thereby ensuring perfect alignment with highly specific functional, aesthetic, and stringent regulatory requirements. This bespoke, engineering-driven approach is particularly valuable for complex installations, challenging and varied terrains, or projects demanding distinctive corporate branding and architectural integration.

- Custom Height and Style Variations: Specialized custom heights can range from low-profile, purely decorative fences to imposing tall privacy or high-security barriers. Styles can be meticulously adapted, incorporating specific picket spacing, unique rail configurations, or custom post cap designs to meet precise client specifications.

- Precision Color Matching: Beyond standard white, tan, or grey options, specialized color compounds can be precisely formulated and extruded to flawlessly match corporate branding guidelines or specific architectural palettes, ensuring seamless and harmonious integration with the surrounding environment.

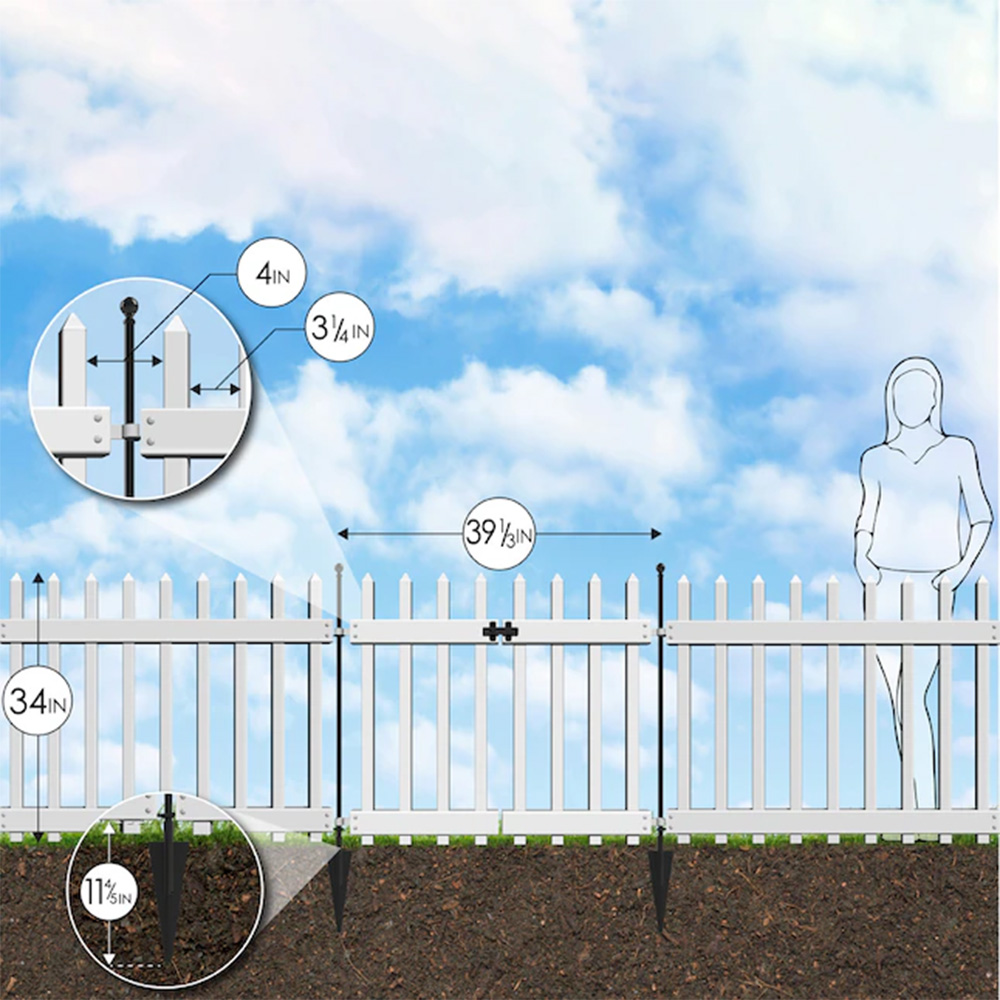

- Integrated Gate Systems: Custom-fabricated gates (available as single-swing, double-swing, or cantilever sliding configurations) can be meticulously designed to match the fence style perfectly, incorporating advanced access control systems, heavy-duty commercial-grade hinges, and robust locking mechanisms precisely tailored to specific security requirements.

- Advanced Adaptability for Uneven Terrain: Innovative solutions utilizing `adjustable vinyl fence panels` are precisely engineered to flawlessly follow the contours of sloped or undulating land, thereby providing a perfectly consistent top line and entirely eliminating stepped installations. This advanced capability is absolutely crucial for maintaining visual integrity, maximizing security, and preventing potential security gaps.

- Solutions for Complex Angles and Layouts: For sites characterized by non-standard property lines or intricate architectural features, `angled vinyl fence panels` are custom-cut and precisely fitted to ensure continuous, unbroken fencing without awkward transitions, thereby meticulously preserving both aesthetic continuity and robust security.

- Incorporation of Decorative Elements: The strategic integration of specialized post caps, elegant lattice tops, or `arched vinyl fence panels` can significantly elevate the overall visual appeal of the installation, providing a distinctive and premium finish that is particularly impactful in high-visibility areas.

- Integrated Structural Reinforcement: For installations situated in high-wind zones or areas demanding significantly enhanced impact resistance, internal steel or aluminum reinforcements can be seamlessly integrated into vinyl posts and rails during the manufacturing process, providing superior structural rigidity and unparalleled resilience.

Real-World Application Case Studies

Case Study 1: Large-Scale Industrial Perimeter Security at a Petrochemical Facility

Client: A leading international petrochemical processing facility strategically located in a highly corrosive coastal region.

Challenge: The existing metal perimeter fencing suffered from alarmingly rapid corrosion due to persistent saline air exposure and direct chemical interaction, necessitating frequent and costly maintenance and premature replacement cycles. A durable, entirely non-corrosive, and exceptionally low-maintenance perimeter solution was critically required to secure hazardous operational areas and meticulously delineate property lines across several kilometers of diverse terrain, including significant sloped sections.

Solution: A highly robust, custom-height vinyl panel fence system was meticulously engineered and deployed. This system utilized heavy-duty vinyl profiles with strategically integrated internal steel reinforcement to achieve superior wind resistance in the exposed coastal environment. Crucially, a specialized chemical-resistant uPVC formulation was employed, and `adjustable vinyl fence panels` were flawlessly deployed to navigate significant elevation changes across the expansive site, meticulously maintaining a uniform top line without any stepping. The inherent non-conductive nature of vinyl also provided an invaluable safety enhancement around critical electrical substations.

Outcome: The petrochemical facility successfully achieved a highly secure, aesthetically consistent, and functionally robust perimeter that is entirely immune to corrosion and requires virtually no ongoing maintenance, resulting in substantial and measurable operational cost savings and significantly enhanced safety protocols. The projected service life of the vinyl fence system demonstrably far exceeds that of the previous metal fencing, showcasing a superior Total Cost of Ownership (TCO).

Case Study 2: High-End Multi-Residential Development with Complex Architectural Requirements

Client: A prominent, nationally recognized property developer constructing an exclusive gated community replete with extensive shared amenities.

Challenge: The developer required an elegant, aesthetically consistent privacy fence solution for individual backyards and expansive common areas, including a crucial community swimming pool. Paramount considerations included enduring aesthetics, long-term durability, and minimal upkeep requirements to consistently maintain the development's premium appeal. The intricate architectural design also mandated the inclusion of sophisticated decorative elements and seamless integration around numerous complex architectural features and varied property lines.

Solution: A highly customized full-privacy vinyl panel fence system, distinguished by `arched vinyl fence panels` as elegant decorative accents, was meticulously selected. The fence was precisely manufactured in a specific custom color formulation to impeccably complement the development's sophisticated architectural palette. For the critical pool area, a code-compliant privacy fence, featuring self-closing and self-latching gates, was installed, purposefully incorporating smooth surfaces for enhanced child safety. `Angled vinyl fence panels` were strategically employed to expertly navigate the complex perimeters of clubhouse gardens and individual property lines, thereby creating a fluid, integrated, and harmonious visual appearance across the entire development.

Outcome: The development now proudly features a visually stunning, architecturally uniform, and exceptionally durable fencing solution that significantly enhances both property value and resident satisfaction. The virtually zero-maintenance nature ensures that the pristine appearance of the fencing is reliably retained for many decades, entirely eliminating ongoing repainting or costly repair expenditures for the Homeowners Association (HOA).

These detailed case studies unequivocally underscore the advanced adaptability, superior performance, and demonstrable long-term value of expertly designed and precisely manufactured vinyl panel fence systems in consistently meeting and reliably exceeding highly complex client expectations across diverse and demanding sectors.

Authoritativeness, Trustworthiness, and Support

Establishing profound trust and consistently demonstrating undisputed authority are absolutely paramount in all B2B engagements. Our unwavering commitment to excellence in vinyl panel fence manufacturing is fundamentally underpinned by the implementation of stringent quality protocols, adherence to recognized industry certifications, transparent operational procedures, and an unwavering dedication to comprehensive customer support. We leverage extensive decades of proven experience serving a highly diverse portfolio of esteemed clients, ranging from large-scale industrial complexes to sophisticated commercial developers, thereby ensuring that every single project benefits from our deep, proven expertise and meticulous attention to detail.

Certifications and Industry Compliance

Our state-of-the-art manufacturing facilities operate under strict adherence to the internationally recognized ISO 9001:2015 quality management systems, which rigorously guarantee consistent product quality and optimal process efficiency across all production stages. All our vinyl panel fence products are meticulously designed, extensively tested, and certified to meet or demonstrably exceed relevant international industry standards, including but not limited to ASTM F964 for critical material properties and performance characteristics. This ensures unparalleled reliability and inherent safety across all conceivable applications. Furthermore, our raw materials and finished products are consistently subjected to rigorous in-house and accredited third-party testing for crucial attributes such as UV resistance (ASTM G154), impact strength (ASTM D256), and long-term chemical stability (ASTM D543), conclusively confirming their exceptional suitability for even the harshest and most demanding operational environments.

Clientele and Decades of Experience

With a proud legacy spanning over 20 years of highly specialized experience in advanced metal and PVC product manufacturing, we have assiduously cultivated enduring partnerships with leading enterprises across the petrochemical, metallurgy, critical water infrastructure, commercial development, and agricultural sectors. Our extensive, proven project portfolio and consistently positive client feedback serve as an irrefutable testament to our unparalleled capability to reliably deliver high-performance, exceptionally durable vinyl panel fence solutions, irrespective of project scale, complexity, or geographical challenges. We are renowned for our steadfast commitment to client satisfaction and engineering excellence.

Frequently Asked Questions (FAQ)

Warranty Commitments and Dedicated After-Sales Support

Our profound confidence in the inherent durability, advanced engineering, and superior quality of our vinyl panel fence products is robustly reflected in our comprehensive warranty offerings. We provide an extensive limited lifetime warranty that explicitly covers manufacturing defects, significant material degradation (e.g., excessive fading, cracking, splintering, or rotting) under normal and intended use conditions. This exceptional warranty conclusively ensures that your significant investment is meticulously protected for many decades. Furthermore, our dedicated after-sales support team comprises highly experienced technical specialists who provide expert technical assistance, detailed installation guidance, and proactive troubleshooting support. This comprehensive support ensures seamless project execution and guarantees long-term operational satisfaction for our valued B2B clients. We are unwavering in our commitment to being a consistently reliable and responsive partner throughout the entire lifecycle of your sophisticated fencing solution.

Authoritative References

- American Society for Testing and Materials. ASTM F964: Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) Gasketed Sewer Fittings. ASTM International.

- International Organization for Standardization. ISO 9001:2015: Quality management systems — Requirements. ISO.

- American Society for Testing and Materials. ASTM G154: Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials. ASTM International.

- The Vinyl Institute. "Vinyl Fencing: Advantages and Benefits." The Vinyl Institute, 2023.

- Modern Plastics Magazine. "Advances in PVC Extrusion Technology for Building Materials." Technical Report, Q3 2022.

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy