Industrial Rack Storage Systems - Efficient Warehousing Solutions

أغسطس . 30, 2024 09:42

Industrial Rack Storage Systems Optimizing Space and Efficiency

In today’s rapidly evolving industrial landscape, the need for efficient storage solutions has never been more critical. Industrial rack storage systems have emerged as essential components for businesses aiming to optimize space, enhance productivity, and streamline operations. These systems not only help in organizing inventory but also play a pivotal role in maximizing warehouse efficiency.

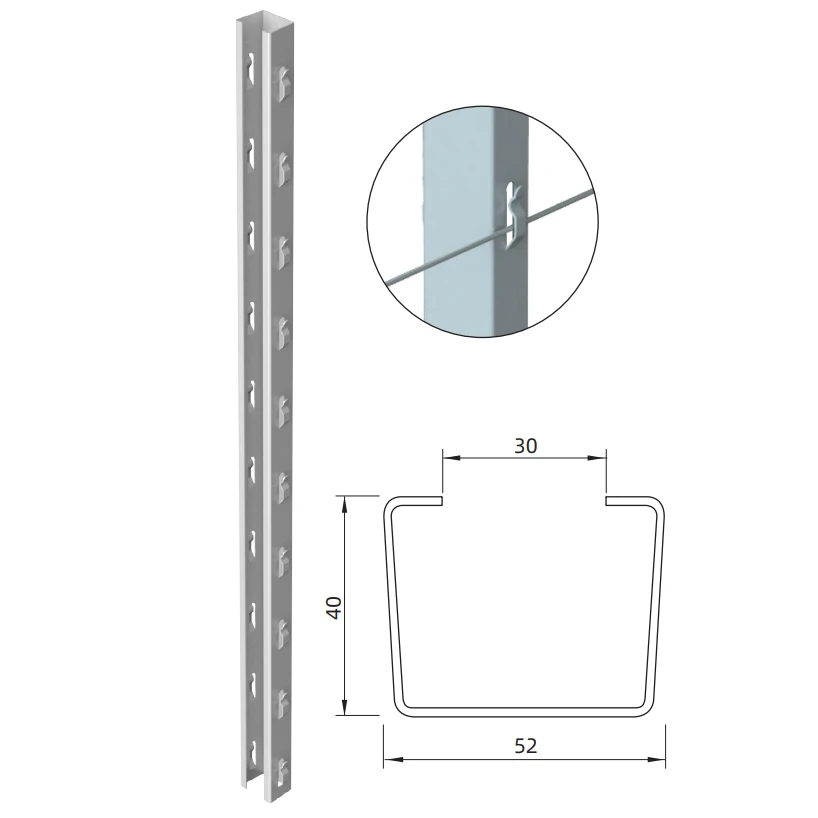

At their core, industrial rack systems are designed to support and organize various types of goods within a warehouse or distribution center. They come in various forms, including selective racks, drive-in racks, FIFO (First-In, First-Out) racks, and cantilever racks, each serving unique purposes tailored to different types of inventory. For instance, selective racks are widely used for palletized loads, allowing easy access to individual pallets, whereas cantilever racks are ideal for storing long, bulky items like pipes or lumber.

One of the most significant advantages of industrial rack storage systems is their ability to utilize vertical space effectively. In many warehouses, upward expansion is often a more feasible option than horizontal spread, particularly in urban areas where space is limited. By stacking goods vertically, businesses can significantly increase their storage capacity without expanding their physical footprint. This vertical storage capability not only allows for more products to be stored but also leads to more efficient picking processes, as items can be organized according to their frequency of use.

industrial rack storage systems

Moreover, industrial rack systems enhance operational efficiency. Properly organized racks streamline the picking and packing processes, reducing the time employees spend searching for items. With specific configurations, such as flow racks, businesses can ensure a systematic approach to inventory rotation, minimizing the risk of obsolescence and spoilage in perishable goods. Additionally, these systems often integrate with warehouse management systems (WMS), enabling real-time inventory tracking, which further boosts efficiency.

Safety is another pivotal aspect of industrial rack design. These systems are built to meet stringent safety standards, ensuring that they can withstand heavy loads and environmental stresses. Regular inspections and maintenance are crucial to keeping these systems safe and operational. An improperly maintained storage system can lead to catastrophic failures, potentially harming employees and disrupting business operations. Therefore, investing in quality rack systems and committing to regular maintenance can safeguard both personnel and inventory.

Furthermore, with the rise of e-commerce and just-in-time delivery models, businesses increasingly rely on industrial rack storage systems to adapt to ever-changing demands. Flexibility in design allows warehouses to quickly reconfigure their storage solutions based on fluctuating inventory needs and seasonal trends.

In conclusion, industrial rack storage systems represent a fundamental aspect of modern warehousing and inventory management. By optimizing space, enhancing safety, and increasing operational efficiency, these systems play a crucial role in helping businesses meet their logistical challenges. As industries continue to evolve, the importance of smart storage solutions will only grow, driving further innovations in rack storage design and implementation. Investing in these systems is not merely an operational choice; it is a strategic move towards ensuring long-term success in a competitive marketplace.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution