Expanded Wire Mesh | Durable, Versatile & Affordable Solutions

Aug . 21, 2025 19:00

The Versatility and Engineering Excellence of Expanded Wire Mesh

In the vast landscape of industrial materials, expanded wire mesh stands out as a uniquely versatile and highly engineered product. Far from being a simple screen, it is a single, integral piece of metal that has been uniformly slit and stretched, creating a diamond-shaped or hexagonal pattern with an open, rigid structure. This distinctive manufacturing process imbues it with exceptional strength, an impressive strength-to-weight ratio, and a myriad of functional and aesthetic advantages, making it indispensable across countless sectors. From heavy industrial applications requiring robust security and filtration to intricate architectural designs demanding both form and function, the adaptability of expanded wire mesh is truly remarkable. This comprehensive guide will delve into the intricate details of its production, technical specifications, diverse applications, and the critical factors discerning buyers consider when sourcing a reliable expanded wire mesh supplier.

Understanding the core characteristics of expanded mesh is crucial for engineers, procurement specialists, and project managers looking for optimal material solutions. Its inherent properties, derived directly from its unique manufacturing method, offer significant benefits over alternative materials, particularly in scenarios demanding high performance, durability, and cost-efficiency. As we explore the subject, we will highlight industry trends, present crucial data, and discuss the nuances that differentiate a superior product in the competitive market of expanded metal mesh for sale.

The Science Behind the Structure: Manufacturing Expanded Wire Mesh

The production of expanded wire mesh is a sophisticated mechanical process that transforms solid metal sheets into an open, diamond-patterned grid without any welding or weaving. This ingenious method begins with a solid sheet of metal, which is simultaneously slit and stretched in a single operation. Unlike woven or welded mesh, where individual strands are interconnected, expanded mesh retains its monolithic integrity, making it inherently stronger and more resistant to unraveling, fraying, or stress points.

Raw Materials Selection: The Foundation of Performance

The performance characteristics of expanded wire mesh are fundamentally determined by the choice of raw material. Manufacturers commonly utilize a range of metals, each selected for its specific properties that align with the intended application:

- Carbon Steel: Economical and strong, ideal for general construction, security fencing, and industrial applications where corrosion resistance is not the primary concern or where a protective coating will be applied.

- Galvanized Steel: Carbon steel coated with a layer of zinc, offering enhanced corrosion resistance, making it suitable for outdoor environments or applications exposed to moisture.

- Stainless Steel (e.g., 304, 316): Renowned for exceptional corrosion resistance, high tensile strength, and aesthetic appeal. Stainless steel expanded mesh is preferred in corrosive environments such as marine, chemical processing, and food industries, or for architectural applications requiring a clean, durable finish. Type 316 offers superior resistance to pitting and crevice corrosion, particularly in chloride-rich environments, compared to 304.

- Aluminum: Lightweight, corrosion-resistant, and non-magnetic. Aluminum expanded mesh is often used in aerospace, automotive, HVAC, and decorative applications where weight is a critical factor.

- Special Alloys: For highly specialized applications, materials like nickel alloys, copper, or titanium can be expanded, offering unique properties such as extreme temperature resistance, specific electrical conductivity, or superior chemical inertness.

The Slitting and Stretching Process (Diagrammatic Description)

The manufacturing of expanded wire mesh is a continuous, high-speed operation. It begins with a coil or sheet of metal being fed into an expanding machine. This machine utilizes a series of dies and knives that simultaneously slit and stretch the metal. As the metal is stretched, the slits open up, forming the characteristic diamond-shaped openings. The process is precisely controlled to maintain consistent strand width, strand thickness, and opening dimensions (SWD - Short Way of Design, LWD - Long Way of Design). The primary advantage of this method is the creation of a seamless, integral structure with no welds or interlocked strands, eliminating potential weak points found in other mesh types. This leads to a higher strength-to-weight ratio and greater structural integrity.

Quality Control and Inspection Standards

Adherence to stringent quality control and inspection standards is paramount for a reputable expanded wire mesh supplier. Key standards and certifications include:

- ISO 9001: This international standard for quality management systems ensures that manufacturers consistently provide products and services that meet customer and regulatory requirements. An ISO 9001 certified expanded mesh producer demonstrates commitment to quality at every stage.

- ASTM International Standards: Various ASTM standards apply to the material properties and testing of expanded wire mesh. For example, ASTM A36 for carbon steel, ASTM A240 for stainless steel, and ASTM B209 for aluminum sheets are crucial for ensuring the base material quality. For expanded metal products specifically, ASTM F1267 (Standard Specification for Metal Expanded Grating) is often referenced for heavy-duty applications, while other internal and industry standards govern lighter gauges and specific mesh types.

- Dimensional Accuracy Checks: Precise measurements of SWD, LWD, strand width, and overall thickness are crucial. Calipers, micrometers, and optical measurement systems are used to ensure that the mesh conforms to specified tolerances.

- Material Composition Analysis: Spectroscopic analysis (e.g., XRF) can verify the chemical composition of raw materials and finished products, ensuring they meet specified alloy requirements.

- Surface Finish and Coating Inspection: For galvanized, powder-coated, or anodized expanded mesh, checks for coating thickness, adhesion, and uniformity are performed to ensure longevity and aesthetic quality.

- Strength and Load-Bearing Tests: For specific applications like gratings or platforms, load-bearing tests may be conducted to confirm the mesh's structural integrity under expected loads, adhering to design specifications.

These rigorous inspection protocols ensure that the final expanded wire mesh product delivers reliable performance, extended service life, and meets the exact specifications required by demanding industrial and architectural projects.

Decoding Expanded Wire Mesh: Technical Parameters and Specifications

To effectively specify and procure expanded wire mesh, it's essential to understand its key technical parameters. These measurements define the mesh's physical characteristics, open area, strength, and suitability for various applications. Below is a table summarizing common parameters and their typical ranges, followed by a detailed explanation.

| Parameter | Description | Typical Range | Impact on Application |

|---|---|---|---|

| SWD (Short Way of Design) | Distance from a point on one bond to the corresponding point on the opposite bond across the short dimension of the diamond. | 3 mm to 76 mm | Determines opening size; impacts filtration, screening, and aesthetic appearance. |

| LWD (Long Way of Design) | Distance from a point on one bond to the corresponding point on the opposite bond across the long dimension of the diamond. | 6 mm to 150 mm | Contributes to open area, flow characteristics, and visual pattern. |

| Strand Width | The amount of metal fed through the expanding machine to create one strand. | 0.5 mm to 8 mm | Directly impacts the strength and weight of the mesh; wider strands mean stronger mesh. |

| Strand Thickness (Gauge) | The thickness of the original metal sheet from which the mesh is expanded. | 0.3 mm to 6 mm | Also directly impacts strength and rigidity; thicker strands provide greater load-bearing capacity. |

| Overall Thickness (Overall Depth) | The measurement from the top plane to the bottom plane of the expanded mesh (for standard, non-flattened mesh). | 1.5 mm to 30 mm | Important for grating applications where flushness or elevation is critical. |

| Open Area Percentage | The percentage of the total surface area that is open, allowing for passage of light, air, and fluids. | 30% to 85% | Crucial for ventilation, filtration efficiency, light transmission, and acoustic properties. |

| Weight per Square Meter | The weight of the expanded mesh per unit area, typically in kg/m² or lbs/ft². | 0.5 kg/m² to 50 kg/m² | Important for structural load calculations, transportation costs, and overall project weight. |

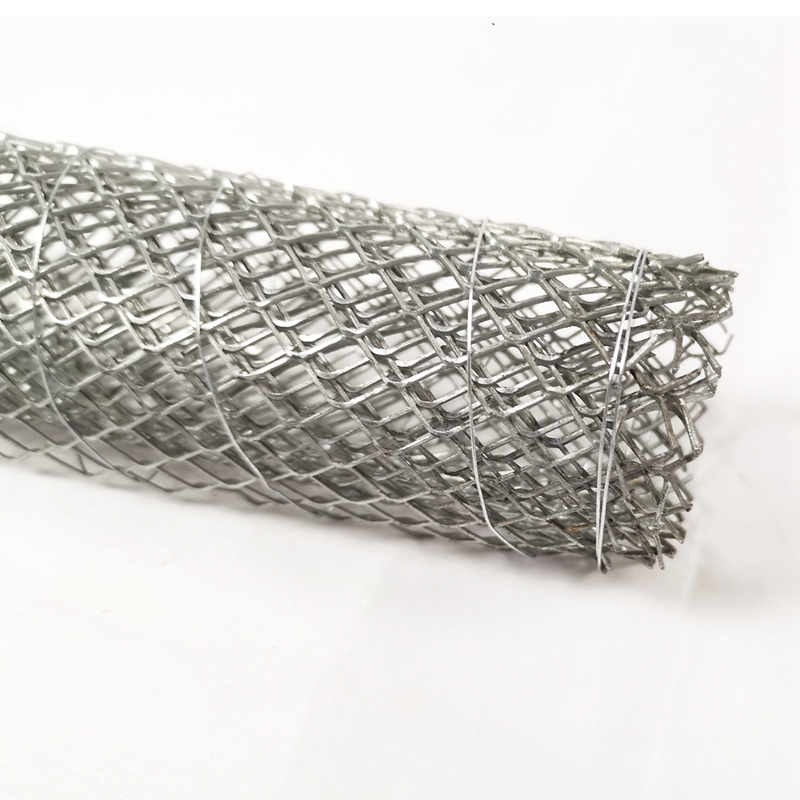

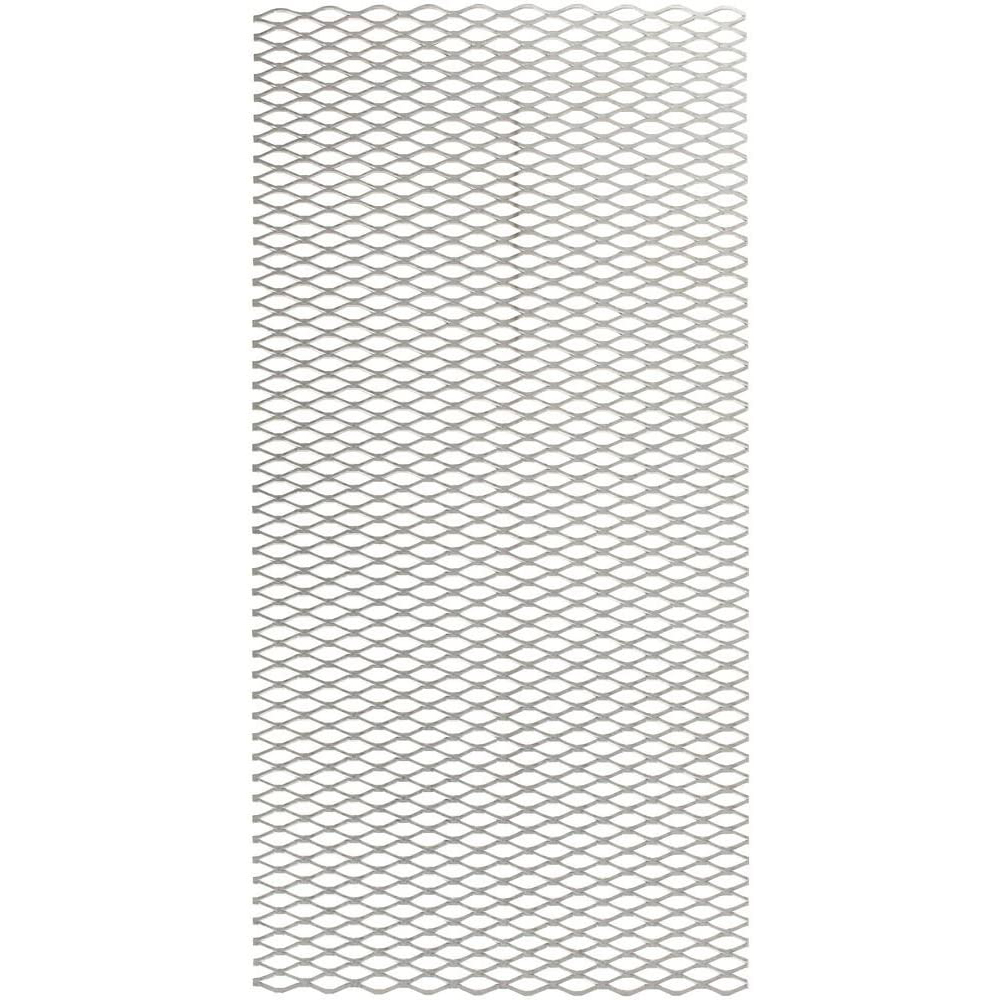

Beyond these core dimensions, expanded wire mesh can also be produced in various forms:

- Standard (Raised) Expanded Mesh: The original form, where the strands are set at a uniform angle to the plane of the sheet, creating a raised, textured surface that offers excellent slip resistance.

- Flattened Expanded Mesh: Produced by cold rolling standard expanded mesh, which flattens the strands and bonds into a smooth, level surface. This process reduces the overall thickness and provides a more aesthetically pleasing, uniform appearance, while still maintaining high strength. Flattened expanded mesh is often preferred for applications where a smooth surface is required, such as architectural infill panels or decorative grilles.

- Anodized/Coated Expanded Mesh: Available with various finishes, including galvanizing for corrosion protection, powder coating for aesthetic appeal and additional durability, or anodizing for aluminum meshes.

Careful consideration of these parameters, in conjunction with the chosen material, ensures that the selected expanded metal mesh for sale perfectly matches the demands of your specific project, optimizing performance and maximizing cost-efficiency. A reliable expanded wire mesh supplier will provide detailed specification sheets and assist in selecting the ideal product configuration.

Diverse Applications Across Industries: Where Expanded Wire Mesh Excels

The inherent versatility and robust properties of expanded wire mesh enable its deployment across an extraordinarily wide range of industries and applications. Its combination of strength, open area, and adaptability makes it a superior choice for many functional and protective roles. Here’s a detailed look at its primary application sectors:

1. Petrochemical and Chemical Industries

In environments where safety, ventilation, and corrosion resistance are paramount, expanded mesh is extensively used. Common applications include:

- Walkways, Platforms, and Catwalks: Standard (raised) expanded steel or aluminum mesh provides exceptional anti-slip properties, even when wet or oily, ensuring worker safety in refineries, chemical plants, and offshore platforms. Its open structure allows for efficient drainage of liquids and prevents the accumulation of debris, reducing maintenance.

- Security Fencing and Cages: For protecting sensitive equipment or restricting access to hazardous areas, the robust, anti-climb nature of expanded mesh is invaluable.

- Filtration and Separation: Used in various filters, strainers, and screens for process fluids, gases, and particulates due to its uniform openings and high flow rates.

- Safety Guards and Enclosures: Protecting machinery and personnel from moving parts.

2. Metallurgy and Mining

The mining and metallurgy sectors demand materials that can withstand harsh conditions, abrasion, and heavy loads. Expanded wire mesh is utilized for:

- Screens and Sieves: For sorting and classifying ores, aggregates, and other bulk materials. Its robust, one-piece construction resists deformation under stress.

- Conveyor Guards: Protecting personnel from moving parts of conveyor systems.

- Reinforcement in Concrete: Light and medium gauge expanded mesh can provide reinforcement in concrete structures or rock strata in mining tunnels.

- Ventilation Grilles: Ensuring proper airflow in mines and processing facilities.

3. Water Treatment and Environmental Engineering

In municipal and industrial water treatment plants, expanded mesh plays a critical role in various stages:

- Intake Screens: Preventing large debris from entering pumps and treatment systems.

- Filter Support: Providing structural support for filtration media in wastewater treatment and potable water systems.

- Trench Covers and Grates: Durable and anti-slip covers for drainage systems.

- Aeration Systems: Used in some aeration basins to distribute air.

4. Architectural and Decorative Applications

Beyond its industrial utility, expanded mesh is increasingly prized for its aesthetic appeal and functional elegance in modern architecture:

- Building Facades and Cladding: Provides sun shading, ventilation, and a unique visual texture. The specific patterns and finishes of expanded mesh can transform the appearance of a building while improving energy efficiency by reducing solar heat gain.

- Ceiling Tiles and Wall Panels: Offers acoustic dampening and allows for discreet lighting fixtures or HVAC vents.

- Stair Treads and Balustrades: Combines safety with a modern, industrial aesthetic.

- Security Screens and Grilles: For windows and doors, offering high security without sacrificing light or airflow.

5. Transportation and Automotive

In vehicle manufacturing and infrastructure, expanded mesh contributes to both performance and safety:

- Vehicle Grilles: For protection and airflow in car fronts.

- Battery Enclosures: For electric vehicles, providing ventilation and protection.

- Bridge Decking and Walkways: Lightweight, high-strength grating for pedestrian and maintenance access.

This extensive range of applications underscores the adaptability and robust performance of expanded mesh, making it a preferred choice for engineers and designers seeking reliable, efficient, and durable material solutions across a multitude of sectors. The demand for high-quality expanded metal mesh for sale continues to grow as industries recognize its unique advantages.

Unlocking Value: Key Advantages and Performance Benefits of Expanded Wire Mesh

The widespread adoption of expanded wire mesh across diverse industries is not accidental; it is driven by a compelling set of technical advantages that deliver significant value to projects and operations. These benefits directly stem from its unique manufacturing process and inherent structural integrity.

1. Exceptional Strength-to-Weight Ratio

One of the most defining characteristics of expanded mesh is its superior strength relative to its weight. Because it is a single, integral piece of metal, formed without welds or interlocks, the metal's strength is retained and even enhanced through the expansion process. The bonds and strands act as structural elements, distributing loads efficiently. This makes it an ideal material for applications where reducing dead weight is crucial, such as elevated platforms, bridge decking, or vehicle components, without compromising structural integrity.

2. Superior Air, Light, and Fluid Permeability

The open diamond pattern of expanded wire mesh allows for excellent passage of air, light, heat, and fluids. This property is invaluable in applications like:

- Ventilation Systems: Ensuring efficient airflow in HVAC units, machinery guards, and building facades.

- Filtration: Effective screening of particles while minimizing pressure drop.

- Solar Shading: Reducing solar heat gain in buildings while maintaining natural light, contributing to significant energy savings.

- Drainage: Allowing rapid drainage of liquids, preventing standing water and enhancing safety on platforms and walkways.

3. Enhanced Slip Resistance (for Standard/Raised Mesh)

The angled strands and raised surface of standard expanded wire mesh provide a natural gripping surface. This makes it an excellent choice for stair treads, catwalks, and platforms in industrial settings, significantly reducing the risk of slips and falls, especially in wet, oily, or icy conditions. This inherent anti-slip property contributes directly to workplace safety and compliance with occupational health standards.

4. Durability and Longevity: Corrosion Resistance and Impact Absorption

When manufactured from appropriate materials like stainless steel or galvanized carbon steel, expanded wire mesh offers exceptional corrosion resistance, extending its service life even in harsh environments such as those found in petrochemical or marine applications. Furthermore, its continuous strand design allows it to absorb and distribute impact loads more effectively than welded or woven alternatives, resisting deformation and maintaining structural integrity over time. The typical service life of well-maintained expanded mesh can easily exceed 20-30 years, depending on the environment and material selection.

5. Cost-Effectiveness and Material Efficiency

Despite its engineered properties, expanded wire mesh is highly cost-effective. The expansion process generates very little waste, as the material is stretched rather than cut away. This efficiency in material utilization, coupled with its durability and low maintenance requirements, translates into significant long-term savings. The initial expanded wire mesh price is often competitive, and its extended lifespan reduces replacement costs, offering an excellent return on investment.

6. Versatility and Aesthetic Appeal

The ability to vary mesh patterns, strand dimensions, and materials offers immense design flexibility. From fine, decorative meshes to heavy-duty industrial gratings, expanded mesh can be tailored to meet specific aesthetic and functional requirements. Its distinct appearance adds a contemporary, high-tech look to architectural designs, making it a favorite for modern facades, interior design elements, and public art installations.

These combined advantages underscore why expanded wire mesh continues to be a top choice for demanding industrial, security, and architectural projects worldwide. Partnering with an experienced expanded wire mesh supplier ensures access to products that fully leverage these benefits.

Selecting Your Expanded Wire Mesh Supplier: A B2B Perspective

For B2B buyers, choosing the right expanded wire mesh supplier is a strategic decision that impacts project timelines, product quality, and overall cost-efficiency. It goes beyond merely comparing expanded wire mesh price lists. A reliable supplier acts as a partner, offering expertise, consistent quality, and responsive service. Here are critical factors to consider:

1. Manufacturing Capabilities and Capacity

Assess the supplier's production capabilities. Do they have the machinery to produce the specific mesh types (standard, flattened), materials, and dimensions required for your project? High-volume requirements necessitate a supplier with robust production capacity to ensure timely delivery without compromising quality. Inquire about their typical production lead times for both standard and custom expanded mesh orders.

2. Quality Assurance and Certifications (Authoritativeness)

A commitment to quality is non-negotiable. Look for suppliers holding ISO 9001 certification, which demonstrates adherence to international quality management standards. Ask for material test reports, dimensional inspection certificates, and conformity to relevant ASTM standards (e.g., ASTM F1267 for expanded metal grating). A transparent supplier will readily provide these documents, offering proof of the quality of their expanded wire mesh.

3. Technical Expertise and Support (Expertise)

Can the supplier offer technical advice on material selection, mesh configuration, or fabrication details? For complex projects, engineering support in design, load calculations, or application-specific challenges is invaluable. A knowledgeable expanded wire mesh supplier can help optimize your design, potentially reducing costs and improving performance. Inquire about their experience with similar projects in your industry (e.g., petrochemical, construction, architectural).

4. Customization Capabilities and Flexibility

Many industrial and architectural projects require non-standard mesh sizes, specific cut-to-size panels, or unique finishes. A good expanded mesh manufacturer should offer comprehensive customization services, including precise cutting, forming, welding, and a range of finishing options like powder coating, anodizing, or specialized galvanizing. This flexibility ensures that the product perfectly integrates into your project specifications.

5. Supply Chain Reliability and Logistics

Timely delivery is crucial for project success. Evaluate the supplier's logistics capabilities, including their ability to handle international shipments, packaging standards to prevent damage during transit, and their track record for on-time delivery. A robust supply chain minimizes delays and ensures your project stays on schedule. Inquire about their typical delivery period for standard and bulk orders, as well as their responsiveness to urgent requests for expanded metal mesh for sale.

6. Transparent Pricing and Value Proposition

While expanded wire mesh price is a factor, it should be evaluated in context of the overall value. A lower price might indicate compromises in material quality, manufacturing precision, or after-sales support. Seek transparent pricing that breaks down costs and offers competitive rates for the specified quality and service level. A supplier who provides a clear quotation, detailing material, dimensions, finish, and delivery terms, fosters trust.

By carefully evaluating these aspects, B2B buyers can establish long-term partnerships with reliable suppliers of expanded wire mesh, ensuring consistent quality, technical support, and competitive value for their industrial and construction needs.

Custom Solutions and Project Capabilities (Experience)

While standard sizes and specifications of expanded wire mesh cater to many needs, complex industrial projects and ambitious architectural designs often demand bespoke solutions. A truly professional expanded wire mesh supplier excels in offering comprehensive customization capabilities, transforming conceptual designs into tangible, high-performance products. This involves a collaborative approach, from initial consultation to final fabrication.

Design Consultation and Engineering Support

Custom projects begin with a thorough understanding of the client's requirements. This includes:

- Application Analysis: Understanding the environment (corrosive, high-traffic, aesthetic focus), functional demands (filtration, safety, ventilation), and performance criteria (load-bearing, light transmission).

- Material Selection Guidance: Advising on the optimal material (e.g., 304 vs. 316 stainless steel, aluminum vs. carbon steel) based on cost, durability, and specific environmental factors.

- Mesh Pattern and Size Optimization: Recommending the ideal SWD, LWD, strand width, and thickness to achieve desired open area, strength, and visual effect.

- Fabrication and Finishing Expertise: Discussing possibilities for cutting, forming, framing, welding, and surface treatments (galvanizing, powder coating, anodizing) to ensure the final product meets exact specifications and aesthetic goals.

Precision Fabrication Services

Custom solutions often require more than just expanding. Leading suppliers provide comprehensive fabrication services, including:

- Shearing and Slitting: Cutting expanded mesh panels to precise dimensions required by the client, minimizing waste and site work.

- Forming and Bending: Shaping mesh panels to create complex geometries for architectural features, guards, or enclosures.

- Welding and Framing: Attaching frames or structural supports to expanded mesh panels for easier installation and enhanced rigidity.

- Custom Punching and Notching: Creating specific cutouts or features in the mesh to accommodate pipes, wires, or other structural elements.

Application Case Studies: Illustrating Custom Success

Consider a scenario where a large pharmaceutical plant required custom expanded mesh safety barriers around sensitive machinery. The requirement was for non-corrosive, easy-to-clean barriers that allowed visibility and airflow. A specialized expanded wire mesh supplier consulted with their engineers, recommending flattened 316L stainless steel expanded mesh with a specific diamond pattern for optimal balance of visibility and rigidity. The mesh panels were precisely cut, framed, and electropolished to meet stringent hygiene standards. This tailored solution provided superior safety, enhanced operational efficiency, and complied with all industry regulations, demonstrating the value of a custom approach over off-the-shelf solutions.

Another example involves an urban development project where architectural facades required unique aesthetic elements combined with solar shading. The client specified large panels of anodized aluminum expanded mesh in various colors and open area percentages to create a dynamic visual effect and improve building energy performance. The supplier collaborated with the architects to produce custom-sized, pre-finished panels, ensuring seamless installation and achieving the desired architectural vision. Such projects highlight how custom expanded mesh solutions are not just about meeting specifications but about enabling innovation and superior project outcomes.

Ensuring Trust: FAQ, Delivery, and Warranty (Trustworthiness)

Building long-term relationships in the B2B sector relies heavily on trust, which is fostered through transparency, reliable service, and a clear commitment to customer satisfaction. A top-tier expanded wire mesh supplier provides comprehensive support throughout the entire engagement, from initial inquiry to post-delivery assistance.

Frequently Asked Questions (FAQ) about Expanded Wire Mesh

- Q1: What is the primary difference between standard (raised) and flattened expanded mesh?

A1: Standard expanded mesh has its strands set at an angle to the original plane of the sheet, creating a raised, textured surface that provides excellent anti-slip properties. Flattened expanded mesh is produced by cold rolling standard mesh, resulting in a smooth, flat surface. Flattened mesh is generally thinner and has a different aesthetic, often preferred for architectural or decorative applications where a smooth finish is desired. Both retain the same strength-to-weight ratio. - Q2: How is the "open area" percentage of expanded mesh calculated, and why is it important?

A2: The open area percentage refers to the proportion of the mesh's total surface that is open space. It's calculated based on the SWD, LWD, strand width, and strand thickness. It is critical for applications involving airflow, light transmission, fluid filtration, and visibility. A higher open area means more flow or light, while a lower open area provides more privacy, less glare, or finer filtration. - Q3: Can expanded wire mesh be welded or further fabricated?

A3: Yes, expanded mesh made from weldable materials (like carbon steel or stainless steel) can be welded to frames or other structures. However, due to its inherent one-piece structure, welding directly onto the mesh strands requires specific techniques. It can also be cut, bent, rolled, and formed to various shapes. Specialized fabrication ensures the structural integrity and aesthetic quality of the final product. - Q4: What finishes are available for expanded metal mesh for sale to enhance corrosion resistance or aesthetics?

A4: Common finishes include hot-dip galvanizing (for excellent corrosion protection, especially for carbon steel), powder coating (available in a wide range of colors for aesthetic appeal and additional protection), and anodizing (for aluminum, offering durable and decorative finishes). Stainless steel expanded mesh often requires no additional finish due to its intrinsic corrosion resistance but can be polished or electropolished for specific applications. - Q5: What are the typical lead times and packaging for large orders of expanded mesh?

A5: Lead times vary based on the complexity of the order, material availability, and current production schedule, typically ranging from 2-4 weeks for standard products to 6-8 weeks for highly customized large orders. Packaging is robust, often involving wooden pallets, crates, or steel frames, sometimes with protective wrapping, to prevent damage during transit. Specific packaging requirements can be accommodated upon request from your expanded wire mesh supplier.

Efficient Delivery and Logistics

Timely and secure delivery is a cornerstone of B2B trust. A leading expanded wire mesh supplier understands the critical nature of project schedules and invests in efficient logistics. This includes:

- Global Shipping Capabilities: Experience in navigating international customs and shipping regulations, ensuring smooth cross-border deliveries.

- Robust Packaging: Utilizing industry-standard packaging methods (e.g., wooden pallets, steel frames, protective wrapping) designed to prevent damage during transit, regardless of destination.

- Real-time Tracking: Providing clients with updates on shipment status, offering transparency and predictability.

- Optimized Lead Times: Communicating realistic lead times for production and delivery, and striving to meet or exceed them. For standard expanded wire mesh, orders can often be fulfilled within 10-14 business days, while custom solutions may require additional time for design and fabrication.

Quality Assurance and Warranty Commitment

A reputable expanded wire mesh supplier stands by the quality of its products. This commitment is typically reflected through:

- Material Certifications: Providing certifications for raw materials, ensuring traceability and adherence to specifications (e.g., Mill Test Certificates for steel).

- Rigorous Internal QC: Beyond external certifications, a supplier should have robust internal quality control processes at every stage of manufacturing.

- Product Warranty: Offering a clear warranty against manufacturing defects, typically ranging from 1 to 5 years, depending on the product and application. This provides peace of mind and demonstrates confidence in product durability.

- Responsive Customer Support: A dedicated support team to address any inquiries, technical issues, or concerns that may arise before, during, or after the purchase of expanded mesh.

This comprehensive approach to customer trust ensures that when you choose a leading expanded wire mesh supplier, you are not just purchasing a product, but investing in a reliable partnership for your critical projects.

Future Trends in Expanded Wire Mesh Technology

The landscape of material science and engineering is constantly evolving, and expanded wire mesh is no exception. Future trends indicate a continued expansion of its applications, driven by innovations in materials, manufacturing techniques, and integration with emerging technologies:

- Advanced Materials: Research into new alloys and composite materials will lead to expanded mesh with even higher strength-to-weight ratios, enhanced corrosion resistance, and specific functional properties (e.g., self-cleaning surfaces, enhanced thermal insulation).

- Smart Mesh Integration: The integration of sensors and smart technologies into expanded mesh could enable real-time monitoring of structural integrity, environmental conditions (temperature, humidity), or even energy generation from solar exposure, especially for architectural facades.

- Additive Manufacturing Hybridization: While current production is traditional, future possibilities may explore hybrid manufacturing techniques, potentially combining expanded metal with 3D-printed elements for highly customized or complex structures.

- Sustainable Manufacturing: Increased focus on eco-friendly production processes, utilizing recycled materials, and minimizing waste, further enhancing the environmental profile of expanded wire mesh.

- Increased Architectural Sophistication: As designers push boundaries, expanded mesh will continue to evolve into more intricate patterns, variable density meshes, and sophisticated finishes, allowing for dynamic building envelopes that respond to light and environment.

These trends underscore a future where expanded mesh remains a highly relevant and adaptable material, continually meeting the evolving demands of industry and design.

Conclusion: The Enduring Value of Expanded Wire Mesh

In summary, expanded wire mesh is an exceptional material solution characterized by its unique monolithic construction, offering unparalleled strength, versatility, and cost-effectiveness. Its ability to provide robust security, efficient ventilation, anti-slip safety, and aesthetic appeal makes it an indispensable component across the petrochemical, metallurgical, water treatment, construction, and architectural sectors. The critical factors of material choice, precise technical specifications, and adherence to international quality standards are paramount to harnessing its full potential.

For B2B decision-makers, choosing a reliable expanded wire mesh supplier means partnering with a company that offers not only competitive expanded wire mesh price points but also technical expertise, customization capabilities, stringent quality assurance, and dependable logistics. The comprehensive understanding of `expanded mesh` properties and applications, coupled with a commitment to customer support and innovative solutions, ensures that your projects benefit from the enduring value and performance of this remarkable material. As industries continue to evolve, the adaptability and inherent advantages of expanded wire mesh will secure its position as a preferred choice for current and future engineering challenges.

References

- ASTM International. (n.d.). _ASTM F1267-17: Standard Specification for Metal Expanded Grating_. Retrieved from ASTM Standards.

- ISO. (n.d.). _ISO 9001: Quality management systems – Requirements_. Retrieved from ISO Standards.

- The Expanded Metal Company. (n.d.). _The History of Expanded Metal Mesh_. Retrieved from Industry Publications.

- Metals Handbook Desk Edition. (1998). _ASM International_.

- Corrosion Handbook. (2000). _Edited by Herbert H. Uhlig and R. Winston Revie, John Wiley & Sons_.

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy