Wide Metal Arbor for Enhanced Stability and Durability in Your Projects

Okt . 10, 2024 22:27

The Importance of Wide Metal Arbors in Modern Manufacturing

In the manufacturing industry, precision and stability are paramount. As technology continues to advance and industry requirements evolve, tools and equipment must adapt accordingly. One such component that plays a pivotal role in achieving these objectives is the wide metal arbor. This integral part of various machinery and tools has transformed the landscape of manufacturing processes, enabling greater accuracy and efficiency in operations.

Defining Wide Metal Arbors

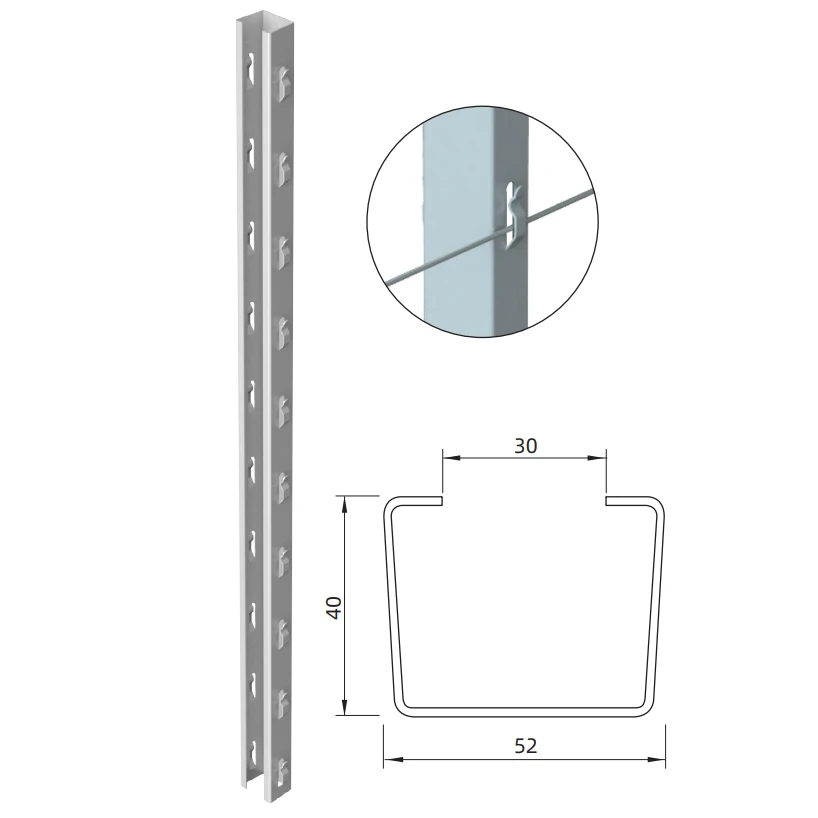

A wide metal arbor is a cylindrical structure, typically made from high-strength alloys or stainless steel, designed to hold and drive cutting tools in various applications, such as milling, drilling, and grinding. Unlike traditional arbors, wide metal arbors feature a broader design that increases surface area contact with the tooling, enhancing stability and reducing vibrations during operations.

Benefits of Using Wide Metal Arbors

1. Enhanced Stability The primary advantage of wide metal arbors is the improved stability they provide. The wider base ensures that the attached tool is less prone to wobbling, which can lead to inaccuracies in the cut. This stability is crucial for high-precision tasks, where even a minute deviation can cause significant issues in the final product.

2. Vibration Dampening Manufacturing environments often experience vibrations from various machinery and processes. Wide metal arbors are designed to absorb and dampen some of these vibrations, which minimizes their impact on the cutting operation. This feature is vital in producing high-quality workpieces with smoother finishes and precise dimensions.

3. Increased Load Capacity Wide metal arbors possess superior load-bearing capabilities. They can accommodate larger tools and withstand the demands of high-pressure cutting operations without compromising their integrity. This translates into less frequent tool changes and downtime, ultimately enhancing productivity.

4. Versatility Across Various Applications These arbors can be utilized across a range of sectors, from aerospace to automotive and beyond. Their ability to support different cutting tools makes them a versatile choice for manufacturers looking to streamline their operations without investing in multiple specialized solutions.

wide metal arbor

5. Material Efficiency The robust design of wide metal arbors allows for optimized material usage. When cutting tools remain stable and perform efficiently, material waste decreases. This efficiency is not only beneficial for cost savings but also for sustainability, as manufacturers strive to minimize their environmental footprint.

The Manufacturing Process

The production of wide metal arbors involves meticulous design and engineering. Advanced computer-aided design (CAD) software is often employed to create precise specifications, which are then fabricated using state-of-the-art machining techniques. Processes such as CNC (Computer Numeric Control) machining ensure that every arbor meets the stringent tolerances required for modern manufacturing applications.

After fabrication, arbors undergo rigorous testing and quality control measures. This includes checks for dimensional accuracy, load capacity, and vibration dampening effectiveness. Only those that pass these stringent tests are deemed suitable for the demanding conditions of industrial use.

Innovations and Future Trends

As industries continue to embrace digital transformation and automation, the demand for advanced tooling solutions like wide metal arbors is expected to rise. Innovations in materials science may introduce even more robust and lightweight alloys, further enhancing their performance. Additionally, the integration of smart technologies, such as sensors and IoT capabilities, could lead to real-time monitoring of arbor performance, providing valuable data for predictive maintenance and operational efficiency.

Conclusion

Wide metal arbors epitomize the convergence of reliability and advanced engineering in the modern manufacturing landscape. They not only contribute to enhanced operational efficiency but also ensure precision and high-quality output across various applications. As manufacturers continue to seek solutions that bolster their performance and productivity, the role of wide metal arbors will undoubtedly become even more significant, paving the way for innovations that drive the industry forward. Emphasizing their importance in manufacturing emphasizes the need for continuous development of these essential components, ensuring that they meet the ever-evolving demands of the market.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution