Ground Screws for Solar Panel Installation Efficient and Durable Solutions

Août . 19, 2024 11:57

The Use of Ground Screws for Solar Panel Installations

As renewable energy sources gain popularity globally, the installation of solar panels has become a common practice. Among the various methods of mounting solar panels, ground screws have emerged as a practical and efficient solution. Ground screws offer several advantages that make them an attractive option for both residential and commercial solar projects.

What are Ground Screws?

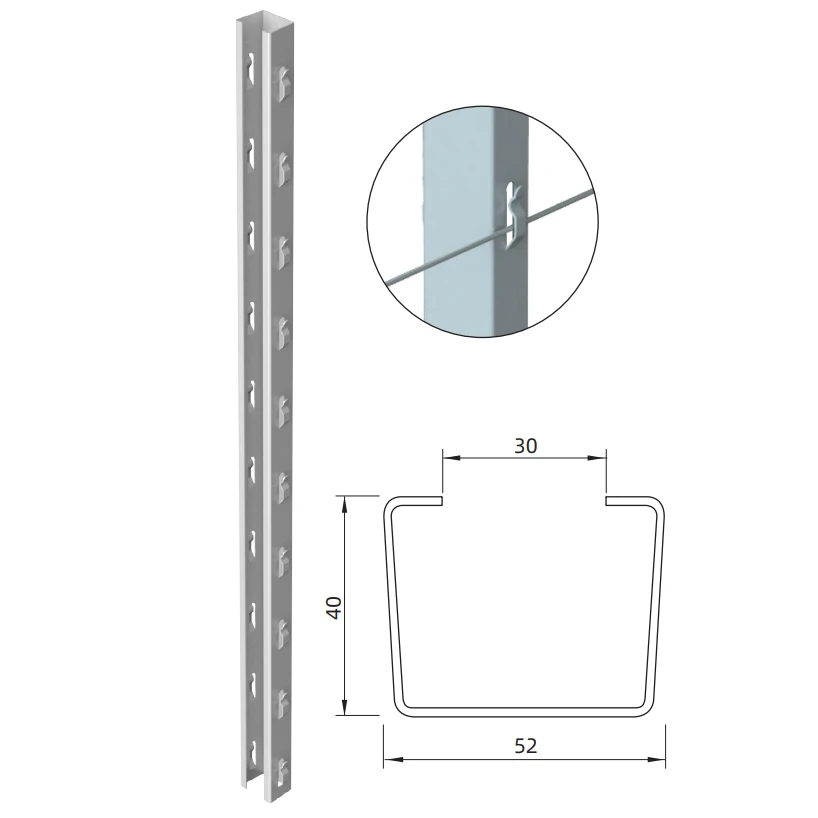

Ground screws are steel posts that are screwed into the ground to serve as a foundation for various structures, including solar panel systems. The design typically features a spiral blade, allowing for easy insertion into the ground. This method minimizes soil disruption and can be installed with minimal excavation required.

Advantages of Ground Screws for Solar Panels

1. Quick Installation One of the most significant benefits of using ground screws is their fast installation time. Unlike traditional concrete footings that require excavation, pouring, and curing, ground screws can be installed quickly, often within a single day. This speed reduces labor costs and allows projects to be completed ahead of schedule.

2. Minimal Environmental Impact Ground screws are less invasive than traditional mounting systems. The installation process disturbs the soil minimally, preserving the surrounding vegetation and ecosystem. This makes ground screws a sustainable choice for solar installations, especially in areas where environmental concerns are paramount.

3. Versatility Ground screws are suitable for various soil types, including clay, sand, and rocky terrain. Their adaptability makes them an excellent option for diverse geographical locations. Additionally, they can be used for both small residential systems and larger commercial installations.

solar panel ground screws

4. Durability Made from robust steel, ground screws are designed to resist corrosion and withstand harsh weather conditions. They provide a stable foundation that can support the weight of solar panels and withstand wind and other forces. Their longevity ensures that solar installations remain secure and productive for many years.

5. Reusability If a solar project needs to be relocated or decommissioned, ground screws can be easily removed and reused. This flexibility adds to their cost-effectiveness and aligns with sustainability practices by reducing waste.

6. Cost-Effectiveness Although the initial cost of ground screws may be slightly higher than other mounting options, the overall savings in installation time and reduced labor costs often make them a more economical choice in the long run. Additionally, their durability reduces the likelihood of costly repairs or replacements.

Considerations for Using Ground Screws

While ground screws present numerous advantages, it is essential to consider a few factors before opting for this mounting solution. First, proper site assessment is crucial to ensure that ground screws can be effectively installed in the specific soil conditions of the installation site. Engaging with qualified solar installers who have experience with ground screw technology can yield the best results.

Additionally, local regulations and permitting requirements must be considered. While ground screws are widely accepted, it is always advisable to check with local authorities to ensure compliance with building codes and regulations.

Conclusion

Ground screws are revolutionizing the way solar panels are installed, offering a fast, effective, and environmentally friendly alternative to traditional mounting methods. Their versatility, durability, and minimal impact on the surroundings make them an excellent choice for solar energy projects. As the demand for renewable energy continues to rise, embracing innovative solutions like ground screws will play a vital role in driving the adoption of solar technology worldwide.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution