Top Wire Mesh Decking Manufacturers | Durable & Custom Solutions

Août . 04, 2025 03:00

Discover Decking Product →

1. Industry Overview: The Rise of Wire Mesh Decking Manufacturers

Wire mesh decking has become the backbone of safe, high-density, and fire-compliant pallet rack storage in modern logistics, warehousing, and industrial facilities. According to Global Market Insights, the international wire decking market exceeded USD 3.5 billion in 2023, with a CAGR of 5.6% driven by automation, e-commerce expansion, and stricter safety codes.

- Pallet rack wire decking is now preferred over wood, plywood, or solid steel for its robust structure, airflow, improved sprinkler penetration, and load rating consistency.

- Top 5 Global Markets: USA, China, Germany, UK, Australia

- Key Segments: Warehousing, Retail Distribution, Chemicals, Automotive, Cold Storage

- Regulatory Push: Adoption of NFPA, ISO, and ANSI standards for rack decking to ensure fire code compliance.

| Manufacturer | Main Standard | Max Load (kg) | Finishing | Certifications | Lead Time (days) | Custom Options | Warranty |

|---|---|---|---|---|---|---|---|

| Decking | ANSI/NFPA/ISO9001 | 1500–3000 | Powder Coating, Galvanized | ISO9001, CE, SGS | 10–21 | Size, Wire Dia, Finish | 5 years |

| Nashville Wire | RMI / NFPA | 1200–2500 | Powder Coating | ISO9001 | 21–28 | Basic | 3 years |

| WireCrafters | ANSI | 900–2000 | Galvanized | ISO/UL | 17–30 | Partial | 3 years |

| Worldwide Material Handling | ISO9001 / OSHA | 1400–2800 | Powder Coating | ISO, SGS | 14–24 | Advanced | 4 years |

| Husky Rack & Wire | NFPA | 1200–2500 | Galvanized | UL/ISO | 21–30 | Basic | 3 years |

2. Core Technical Specs Explained: Wire Mesh Decking Features

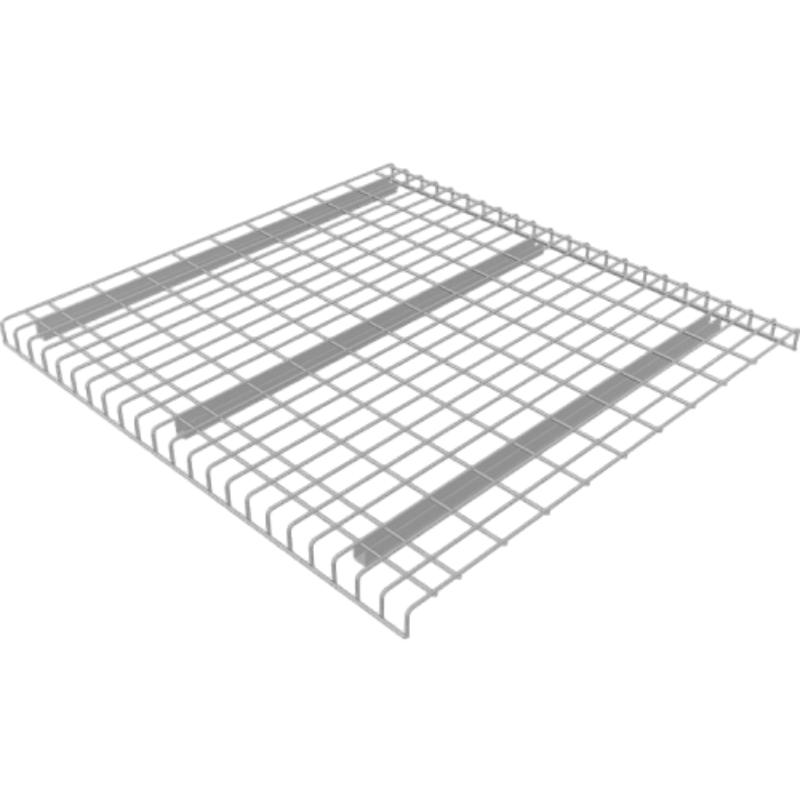

Pallet rack wire decking consists of welded steel wire mesh reinforced with support channels. Precise design variables directly affect safety, life cycle, and application suitability:

Pallet rack wire decking consists of welded steel wire mesh reinforced with support channels. Precise design variables directly affect safety, life cycle, and application suitability:

- Material Grade: High-tensile Q235B/Q345 galvanized or carbon steel (yield strength: 235–355MPa)

- Wire Diameter: 4.0 – 6.0 mm (Industry standard: 5.0 mm for heavy-duty)

- Mesh Grid: 50x100mm (most common), 25x100mm for light loads

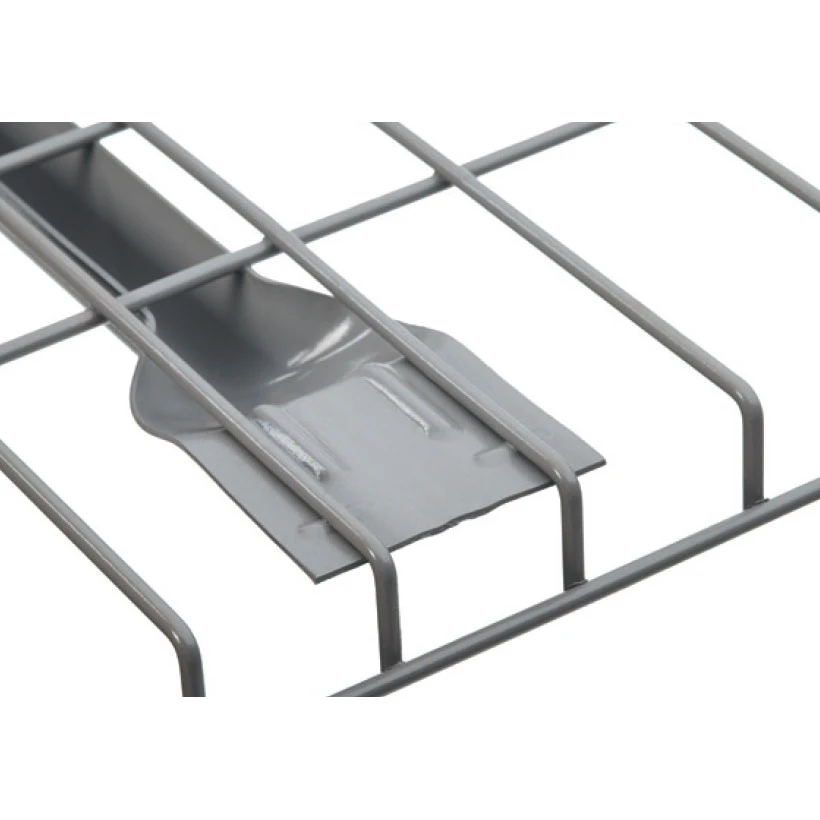

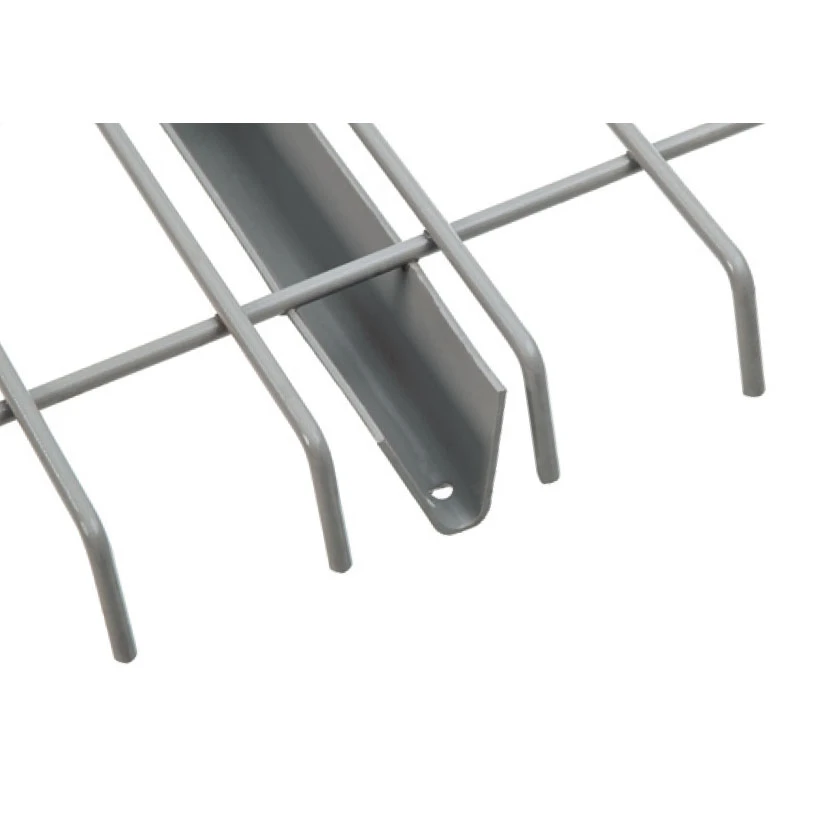

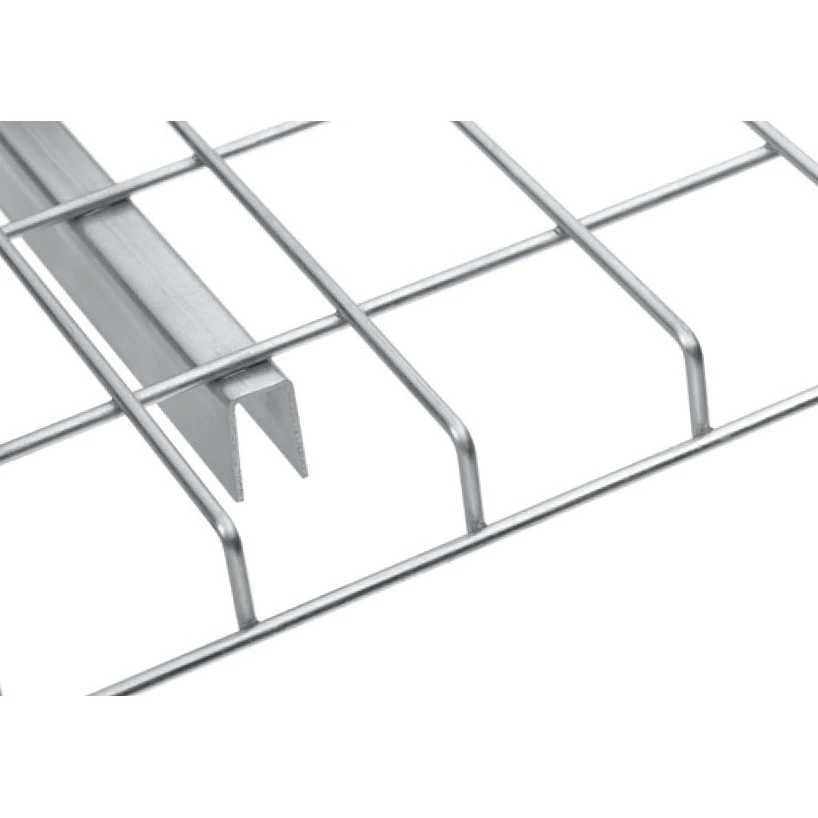

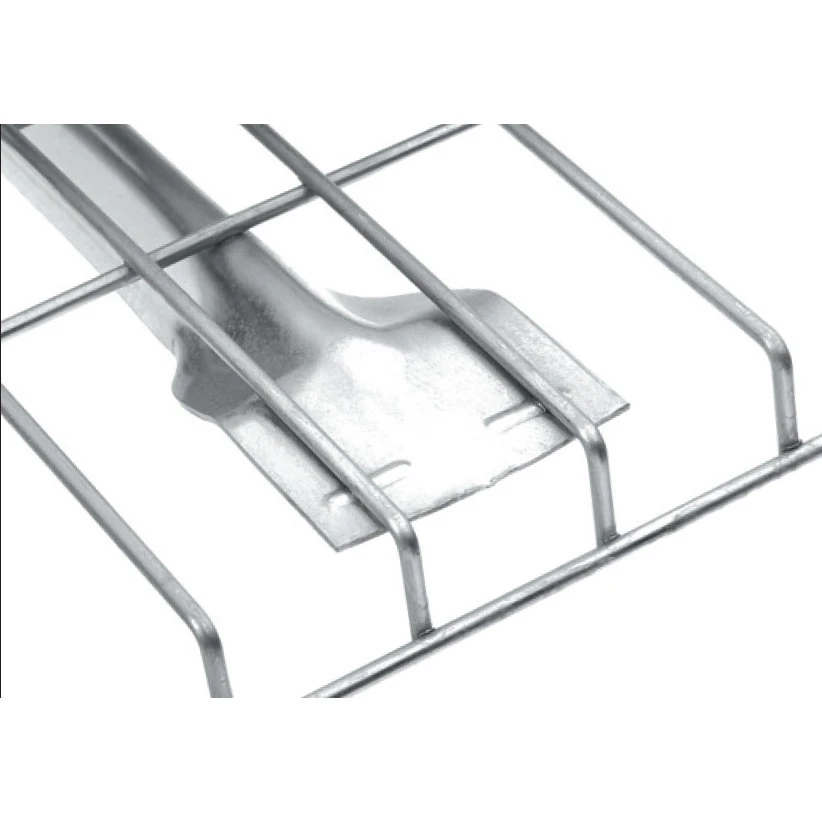

- Support Channel: Waterfall, Step, Flared (see images), thickness 1.5 – 2.5 mm

- Surface Treatment: Hot-dip galvanizing for anti-rust, or electrostatic powder coating (Epoxy)

-

Standard Compliance:

- ANSI MH26.2: Minimum deflection and load rating

- ISO9001: Production quality systems

- NFPA-13: Fire safety (open mesh for sprinkler flow)

- Fire Code: Mesh pattern and open area must comply with fire marshal/local codes for use above automated sprinkler storage

| Dimension (LxWxH, mm) | Wire Dia. (mm) | Mesh (mm) | No. of Channels | Finish | Load Capacity (kg/panel) |

|---|---|---|---|---|---|

| 1200x900x50 | 5.0 | 50x100 | 3 | Galvanized | 1500 |

| 1350x1000x60 | 5.5 | 50x100 | 4 | Powder Coated | 2000 |

| 2700x1100x68 | 6.0 | 25x100 | 5 | HDG | 2800 |

3. Manufacturing Process Flow: From Raw Steel to Premium Decking

Material & Surface Technology

- Galvanization process (>55um zinc) ensures outdoor/harsh workshop durability (salt spray resistance: 480h+)

- CNC-formed channels—step, flared, inverted—for max load with minimal deflection

- Heavy-duty welding and V-notch design for up to 40% extra bending resistance

Testing & Certification

- Each batch tested per ANSI, ISO for load, weld integrity, finish, grid uniformity

- Deflection & ultimate failure tested w/ electronic pressure sensors; UL/SGS certified

4. Market Data Visualization: Product Comparison

| Wire Mesh Decking | Wood Decking | Solid Steel Decking | |

|---|---|---|---|

| Fire Compliance | Excellent (NFPA13) | Poor | Average |

| Load Capacity (kg) | 1200–3000 | 900–1500 | 2000–2700 |

| Corrosion Resistance | Great (Galvanized) | Poor | Good |

| Installation | Tool-less, drop-in | May need screws | Tool-less |

| Lifespan (years) | 10–15 | 3–5 | 8–12 |

| Cost Efficiency | High (ROI 2–3 yrs) | Medium | Medium-Low |

5. Application Scenarios: Where Pallet Wire Decking Excels

Wire decking for racks is universally adaptable due to its engineered load-carrying design and open mesh format:

Wire decking for racks is universally adaptable due to its engineered load-carrying design and open mesh format:

- E-Commerce Warehouses: Maximized vertical utilization, optimal safety under SKUs, rapid relocation

- Automotive: Oil/chemical resistant finish, support for heavy spares and engine parts

- Cold Chain Logistics: Open mesh prevents ice buildup, supports -30℃ storage

- Food & Beverage: Food-grade powder coating meets FDA/ISO22000 standards for surface safety

- Chemical & Petrochemical: Non-reactive galvanized mesh meets corrosive storage needs

- Pharma Distribution: Easy clean, maintains hygiene, superior visibility for picking automation

6. Customization Capabilities from Leading Wire Mesh Decking Manufacturers

The best wire mesh decking manufacturers offer bespoke solutions—not just off-the-shelf parts. Whether it's high-load AS/RS, corrosive environments, or special rack OEM integrations, customizing Decking enables:

- Flexible grid patterns & thickness, tailored load ratings

- Flared, step, or inverted channel choice per rack beam design

- Brand printing or color coding (for logistics zones)

- Extended size up to 3200mm for very large pallet racks

- ESD anti-static coatings for electronics warehouses

- Accessories: Divider bars, safety stops, drop-in adaptors, load signs

| Model | Custom Size Available | Max Load | Finish Options | Mesh Pattern | Certifications |

|---|---|---|---|---|---|

| Decking–Standard | Yes (800–3200mm) | 1500–3000kg | Powder, Galv, HDG | 50x100mm | ISO9001, CE, SGS |

| Decking–Heavy Duty | Yes | 2800–3800kg | Galvanized | 25x100mm | ANSI, ISO |

7. Case Studies: Real-World Applications

- Project: 55,000 sqm in Germany

- Solution: Custom 2700x1100x68mm Decking (galvanized, 5x support bars)

- Result: 38% reduction in local fire risk insurance, zero maintenance after 2 years

- Usage: Food-grade powder coated mesh with 50x50x6 grid

- NFPA-13 certified; integrated drop-in dividers for batch picking

- Feedback: "No pallet slip, minimized cross-contamination risk" —Site Supervisor

- -30℃ rack operation (epoxy-powder anti-freeze coated)

- Open mesh avoids ice/dust accumulation, improved airflow for refrigeration

- ROI: Expected service life >12 years versus 4 with wood

- Packed bulk part racks with 3000 kg mesh decking

- 100% visual inspection by load sensors and ISO fatigue test report

- Result: Downtime due to floor damage eliminated, increased throughput

8. Authoritative Endorsements & Certifications

9. Delivery, Warranties & Trust

- Lead Time: Standard order 10–21 days; urgent custom batch within 7 work days (subject to factory queue)

- Warranty: Up to 5 years (defects in welds, finish, load rating fully covered)

- Service Support: 12h-48h technical response, project design assistance, after-sales field engineering

- Test Documents: Full delivery includes material cert, batch test sheet, inspection record, and install manual (in English/Spanish/Deutsch)

10. FAQ: Professional FAQ on Wire Mesh Decking Manufacturers

1. What steel grades are generally used in wire mesh decking?

2. How do I determine the required mesh pattern?

3. What installation standards should be followed?

4. How is load capacity validated?

5. What finish is best: powder coating or galvanized?

6. Can I get wire mesh decking for custom/non-standard racks?

7. What certifications should reputable manufacturers have?

11. Why Choose Decking: Summary of Competitive Advantages

- Superior Engineering: Automated welding, CNC channel forming, and 100% batch traceability ensure the wire mesh decking manufacturers like Decking deliver unmatched safety and reliability.

- Fire, corrosion, and load-tested, meeting ANSI/NFPA13/ISO standards

- Global footprint: Export to 65+ countries & major industry certifications

- Custom design, expedited lead time, and robust technical service

- Comprehensive documentation for compliance and GMP environments

References & Further Reading

- RackForum: Wire Decking Standards & Safety FAQ

- Material Handling 24/7: Ensuring Wire Mesh Rack Decking Safety

- NFPA Codes and Standards for Industrial Storage

- RMI/ANSI MH26.2 Standards Overview

- Decking Technical Documentation (ISO9001, SGS)

Pervious

This is the First article