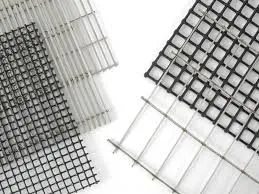

warehouse racking

Déc . 03, 2024 11:11

Understanding Warehouse Racking A Comprehensive Guide

In the fast-paced world of logistics and supply chain management, efficiency and space utilization are critical. One of the most crucial components of this efficiency comes from an effective warehouse racking system. Warehouse racking refers to the framework used for storing goods in a warehouse, enabling organizations to maximize their storage capacity while ensuring easy access to products. In this article, we will discuss the various types of warehouse racking, their benefits, and how to choose the best system for your operations.

Types of Warehouse Racking Systems

1. Selective Racking This is the most common type of racking system, allowing easy access to each pallet. It uses horizontal beams supported by vertical uprights and is ideal for operations with a diverse range of products that frequently require picking. Selective racking maximizes flexibility as it can be adjusted to accommodate different product sizes and weights.

2. Drive-In Racking This system is designed for high-density storage, particularly for large volumes of the same product. Instead of accessing each pallet individually, forklifts can drive in and out of the racking structure, which allows for a more compact storage solution. This system is best suited for businesses that deal with bulk, low-variance products.

3. Push-Back Racking Offering a balance between selective and drive-in racking, push-back systems allow pallets to be stored in a multi-level format. As products are added or retrieved, the pallets roll back on inclined rails. This increases storage density while still providing access to individual pallets.

4. Cantilever Racking Particularly useful for storing long or bulky items, cantilever racking consists of vertical posts with arms protruding from one or both sides. This system provides easy access to products like furniture, pipes, and lumber, making it ideal for industries that require the storage of such items.

5. Pallet Flow Racking This system utilizes gravity to move pallets from the back of the racking system to the front. As a result, it promotes a first in, first out (FIFO) inventory management system, which is essential for perishable goods. The design ensures that products are always accessible while maximizing storage space.

Benefits of Warehouse Racking

Implementing an effective racking system brings a multitude of advantages

warehouse racking

- Maximized Space Utilization By utilizing vertical space and organizing products efficiently, companies can significantly increase their storage capacity, minimizing the need for additional warehouse space.

- Increased Productivity Efficient racking systems allow for quicker access to items, speeding up order fulfillment processes. This increased efficiency can lead to faster turnaround times and improved customer satisfaction.

- Enhanced Safety Properly designed racking systems contribute to a safer working environment by reducing the risk of accidents. Maintaining systematic organization also helps prevent overloading shelves and minimizes the risk of product damage.

- Cost Efficiency By optimizing space and improving workflow, companies can lower overall operational costs. Choosing the right racking system can also reduce labor costs, as employees can work more efficiently when items are easy to access.

Choosing the Right Racking System

When selecting a warehouse racking system, businesses should consider several factors

- Type of Products The nature, size, and weight of the products will dictate the most suitable racking system. For example, heavier items might require more robust racking.

- Inventory Management Understanding how often products are picked can influence the choice of racking. For fast-moving items, a selective system might be best, while slower-moving items can be stored using high-density methods.

- Future Growth It is crucial to consider scalability when deciding on a racking system. An adaptable solution can accommodate future inventory changes without requiring a complete overhaul.

In conclusion, warehouse racking plays a pivotal role in enhancing operational efficiency in logistics and distribution. By understanding the different types of racking systems and their benefits, businesses can make informed choices that optimize storage capacity and streamline their operations.