7% Wire PC Strand Specifications and Applications for Enhanced Structural Integrity

11月 . 05, 2024 23:56

Understanding 7% Wire PC Strand An Overview

The construction and engineering industries rely heavily on various materials to enhance the strength, durability, and longevity of structures. One such material that has gained prominence is the 7% wire PC (prestressed concrete) strand. This article aims to delve into the characteristics, advantages, and applications of 7% wire PC strand and its significance in modern construction.

What is 7% Wire PC Strand?

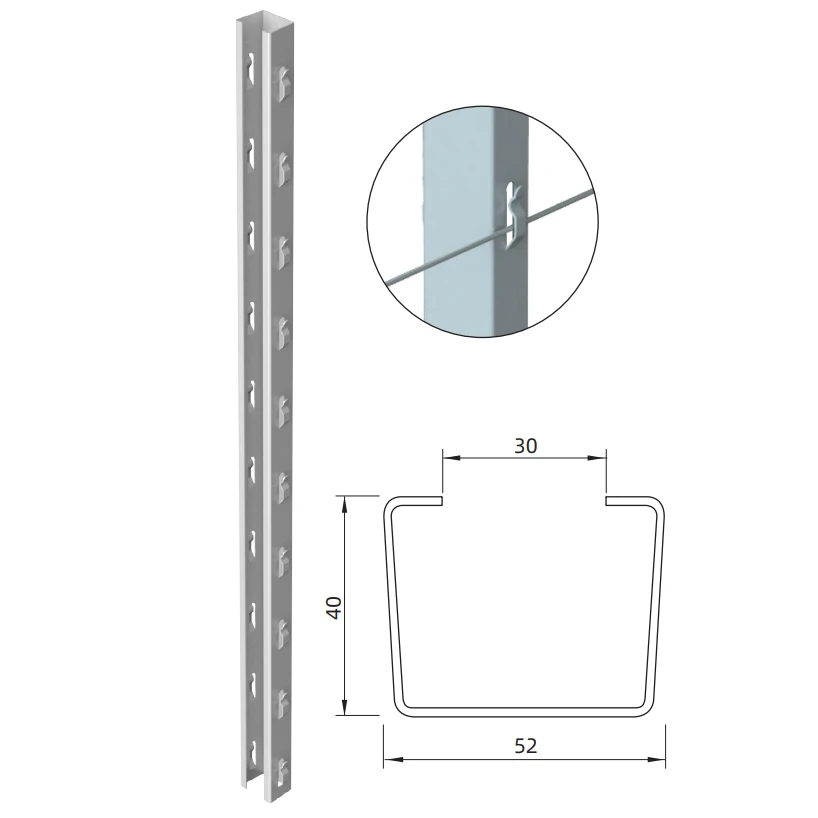

PC strand is a type of pre-tensioned or post-tensioned reinforcement used in concrete structures. It consists of multiple steel wires that are twisted together to form a single strand, offering high tensile strength. The 7% denotes the percentage of the total cross-sectional area of the strand that is made up of wires. Typically, a 7% wire PC strand will have a specific arrangement of seven wires wound together. This design allows for a significant enhancement in strength while maintaining flexibility during the construction processes.

Properties of 7% Wire PC Strand

The 7% wire PC strand boasts several noteworthy properties. Primarily, it exhibits high tensile strength, which translates to increased load-carrying capacity in various applications. The strand is manufactured from high-carbon steel, which provides improved durability and resistance to environmental factors, such as corrosion. This is particularly important for structures exposed to harsh weather conditions or aggressive chemicals.

Another characteristic of the 7% wire PC strand is its ability to withstand deformation. When tension is applied, the strands undergo minimal elongation, ensuring that the structures maintain their integrity under stress. This property is essential when designing bridges, parking garages, and high-rise buildings, where elasticity and resilience are vital for long-term performance.

Advantages of Using 7% Wire PC Strand

7 wire pc strand

One of the primary advantages of using 7% wire PC strand in construction is its efficiency in weight management. Compared to traditional reinforcement methods, the strand can achieve higher load-bearing capacity with less material. This not only reduces the overall weight of the structure but also minimizes the costs associated with heavy equipment and foundation preparation.

Moreover, the use of 7% wire PC strand can expedite the construction process. Its high tensile strength allows for longer spans and smaller beam sizes, leading to reduced formwork and labor requirements. As a result, projects can be completed in less time, meeting tight deadlines and minimizing disruptions.

In addition to its structural benefits, the 7% wire PC strand contributes to sustainability in construction. By utilizing fewer materials while maintaining strong performance characteristics, the environmental impact is lessened. This approach aligns with the growing trend of sustainable practices in the industry, focusing on longevity and minimal resource consumption.

Applications of 7% Wire PC Strand

The applications of 7% wire PC strand are diverse, ranging from bridges and highway systems to parking structures and tall buildings. In bridge construction, the strand allows for longer spans, which reduces the need for numerous supporting columns, thereby enhancing the aesthetic appeal and functionality of the infrastructure.

In commercial and residential buildings, the strand is utilized to create floor slabs, roof structures, and walls that require high load capacities. Additionally, the use of PC strand in precast concrete elements has gained popularity, improving the speed of construction while ensuring superior quality control.

Conclusion

In conclusion, the 7% wire PC strand stands as an essential component in modern construction. With its high tensile strength, durability, and efficiency, it is transforming how engineers and architects approach structural design. As the demand for sustainable and cost-effective materials continues to grow, the 7% wire PC strand is poised to play a pivotal role in shaping the future of construction. Its versatility and performance will undoubtedly pave the way for innovative construction methods and resilient infrastructure that stand the test of time.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution