Enhancing Efficiency in Wire Remeshing Techniques for Improved 3D Model Reconstruction and Performance

Jul . 24, 2024 02:29

Understanding Remesh Wire An Essential Component in Modern Construction

In the realm of construction and engineering, the importance of durable and reliable materials cannot be overstated. Among these materials, remesh wire has garnered attention for its significant role in providing structural integrity and support. This article will delve into what remesh wire is, its applications, and the benefits it offers in various construction projects.

What is Remesh Wire?

Remesh wire, commonly known as welded wire fabric or remesh, consists of a grid of steel wires that are welded together at their intersections. This mesh is typically produced in rolls or sheets and can be fabricated in various sizes and gauges to suit specific project requirements. The wires are usually galvanized to enhance their corrosion resistance, making remesh wire suitable for a wide range of environmental conditions.

Applications of Remesh Wire

Remesh wire is primarily used in concrete reinforcement. It serves to distribute load evenly throughout the structure, reducing the risk of cracking and ensuring durability over time. Some common applications of remesh wire include

1. Reinforced Concrete Slabs In residential and commercial buildings, remesh wire is often embedded in concrete slabs to enhance their strength and stability. This inclusion helps absorb tension forces, particularly in larger slabs that are more prone to cracking.

2. Road and Pavement Construction Remesh wire is used in the construction of roads and pavements, where it provides additional support for surfaces subjected to heavy traffic loads. By reinforcing sidewalks, driveways, and roads, remesh minimizes the potential for surface deterioration and extends the lifespan of these structures.

3. Foundations and Footings The use of remesh wire in foundation work is vital, as it helps reinforce the concrete that supports entire buildings. By enhancing the tensile strength of footings, remesh ensures that the foundational structures can bear heavy loads while maintaining their integrity over time.

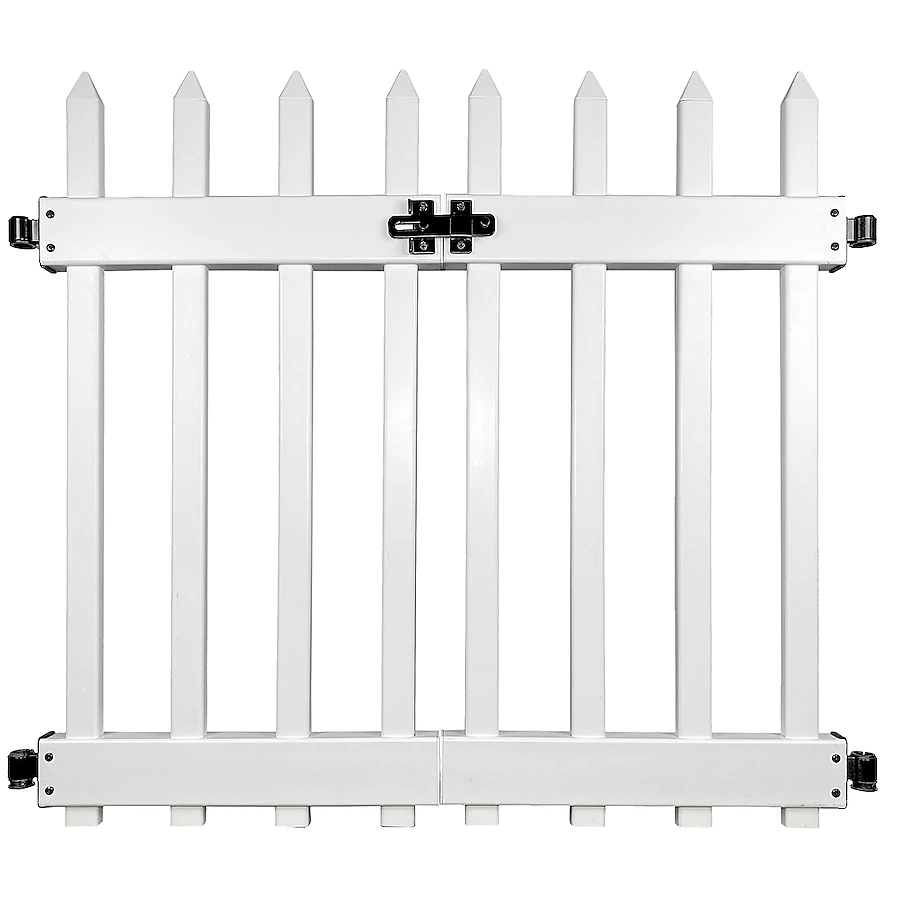

remesh wire

4. Precast Concrete Panels In modern construction, precast concrete panels are becoming increasingly popular. Remesh wire is often incorporated into these panels to provide strength and stability, allowing for quicker installation and reduced on-site labor.

Benefits of Using Remesh Wire

The incorporation of remesh wire in construction brings several advantages

- Enhanced Strength and Durability By preventing cracking and distributing loads, remesh wire significantly increases the lifespan of concrete structures. This reliability makes it a preferred choice for both residential and commercial projects.

- Cost-Effectiveness Utilizing remesh wire can lead to savings in overall construction costs. Its strength allows for reduced concrete thickness, which can lower material costs without sacrificing quality and durability.

- Ease of Installation Remesh wire is relatively easy to handle and install. Contractors can quickly lay it out in the necessary configurations, expediting the construction process.

- Versatility Available in various sizes and gauges, remesh wire can be customized to meet specific project specifications, making it a versatile choice for different applications.

Conclusion

As the construction industry continues to evolve, the demand for effective reinforcement materials like remesh wire will only grow. Its proven performance in enhancing the strength and durability of concrete makes it an essential component in modern construction practices. Whether in commercial buildings, road construction, or residential projects, the use of remesh wire ensures that structures are built to last, providing lasting security and safety for their inhabitants. Given its numerous benefits and applications, remesh wire stands out as a pivotal material in the quest for reliable and sustainable construction solutions.