Exploring the Innovations and Applications of Wire Mesh in Modern Industries and Manufacturing Processes

Aug . 06, 2024 12:26

The Versatility and Importance of Wire Mesh Industries

Wire mesh industries have become a fundamental aspect of various sectors, serving essential functions in agriculture, construction, manufacturing, and more. This versatile material, made from interwoven strands of wire, has a myriad of applications that underscore its significance in today’s industrial landscape.

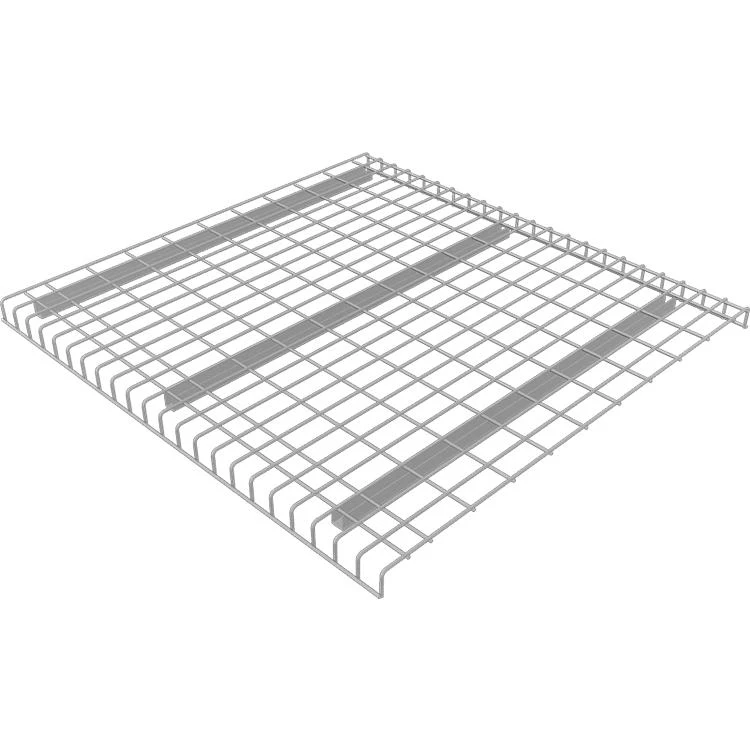

At its core, wire mesh is created by weaving wires together, forming a grid-like structure. The materials used can vary, ranging from stainless steel and aluminum to galvanized iron, each selected based on the intended application and required properties such as corrosion resistance and strength. This adaptability makes wire mesh an invaluable component in both domestic and industrial settings.

The Versatility and Importance of Wire Mesh Industries

In construction, wire mesh plays a critical role in reinforcing concrete structures. Welded wire mesh, in particular, is commonly used to provide additional support and prevent cracks in concrete floors, driveways, and foundations. It is also a popular choice for forming walls, ceilings, and roofs in buildings, ensuring that structures can withstand various stresses and loads. The durability and flexibility of wire mesh make it an engineering staple, crucial for maintaining the integrity of buildings and infrastructure.

wiremesh industries

The manufacturing industry similarly benefits from wire mesh applications. It is often used for filtration and separation processes in various production lines, ranging from food and beverage processing to chemical and pharmaceutical manufacturing. Wire mesh filters can effectively separate liquids from solids, ensuring product purity and quality. Furthermore, industries that require sorting materials often rely on wire mesh screens, which provide an efficient means of sifting through various substances.

Another notable application of wire mesh is in security. Companies and institutions frequently deploy wire mesh systems for fencing around property perimeters, enhancing safety by deterring intruders. Additionally, wire mesh is used in protective barriers and safety nets in various environments, including construction sites, factories, and even sports facilities. Its ability to absorb impact and prevent accidental falls or break-ins is invaluable in maintaining safety.

Despite its many uses, the wire mesh industry is not without challenges. The need for sustainable practices is paramount, as environmental concerns regarding production and disposal methods grow. Many manufacturers are moving towards eco-friendly materials and practices that minimize waste and reduce their carbon footprint, responding to increasing consumer demand for sustainability.

Moreover, technological advancements are paving the way for enhanced wire mesh products. Innovations in materials science are leading to the development of stronger, lighter, and more resilient wire meshes, pushing the boundaries of what this versatile material can achieve. Future applications may see wire mesh integrated into smart technologies, enhancing functionalities in sectors such as telecommunications and data processing.

In conclusion, wire mesh industries play a pivotal role across multiple sectors, providing solutions that enhance safety, efficiency, and utility. As demand continues to grow, the industry must adapt to technological advancements and sustainability challenges. The future of wire mesh not only reflects its historical significance but also points towards innovative possibilities that will redefine its applications in an ever-evolving industrial landscape.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution