Related News

ground screw system

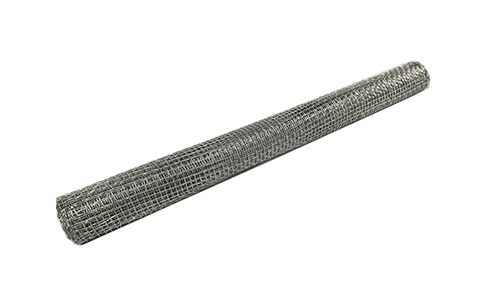

Mar . 07, 2025 06:59The ground screw system is revolutionizing the way we approach foundational construction, offering unparalleled advantages in terms of sustainability, efficiency, and versatility. As a cutting-edge alternative to traditional concrete foundations, ground screws are composed of galvanized steel and are designed to anchor structures such as solar panels, timber buildings, and even road signage securely into the ground. Having emerged as a frontrunner in sustainable construction technologies, the ground screw system’s attributes align perfectly with the growing global emphasis on eco-friendly and economic building practices.

The authority behind the ground screw system can be traced to rigorous testing and certifications from industry-leading organizations. These ground screws meet stringent international standards, verified through comprehensive stress testing and lifecycle assessments. As an engineering marvel, they boast extended lifespans, with corrosion-resistant treatments ensuring longevity under diverse climatic conditions. Planners and architects globally are turning to ground screws, advocating their utility in reducing carbon footprints while maintaining structural resilience. Trust in the ground screw system extends beyond its technical specifications. Contractors and clients alike testify to its reliability across countless successful projects. This trust is bolstered by transparent communications from manufacturers, including detailed technical support and extensive warranties, offering peace of mind and confidence to stakeholders at every stage. Furthermore, its reversibility – the ability to remove and relocate the screws with minimal impact – reinforces its role as a future-proof solution in temporary or evolving land-use scenarios, such as renewable energy installations or modular housing projects. In essence, the ground screw system stands poised as a transformative force in modern construction. Its ability to deliver top-tier structural support with minimal environmental consequences positions it as a leader in sustainable development solutions. Advocates within the engineering community emphasize its role not just as a foundation option, but as a statement towards progressive, responsible building practices where longevity, efficiency, and ecological consideration can harmoniously coexist. As industries continue to prioritize green construction, the adoption of ground screw systems is set to become more widespread, as businesses seek to align their operations with global sustainability goals.