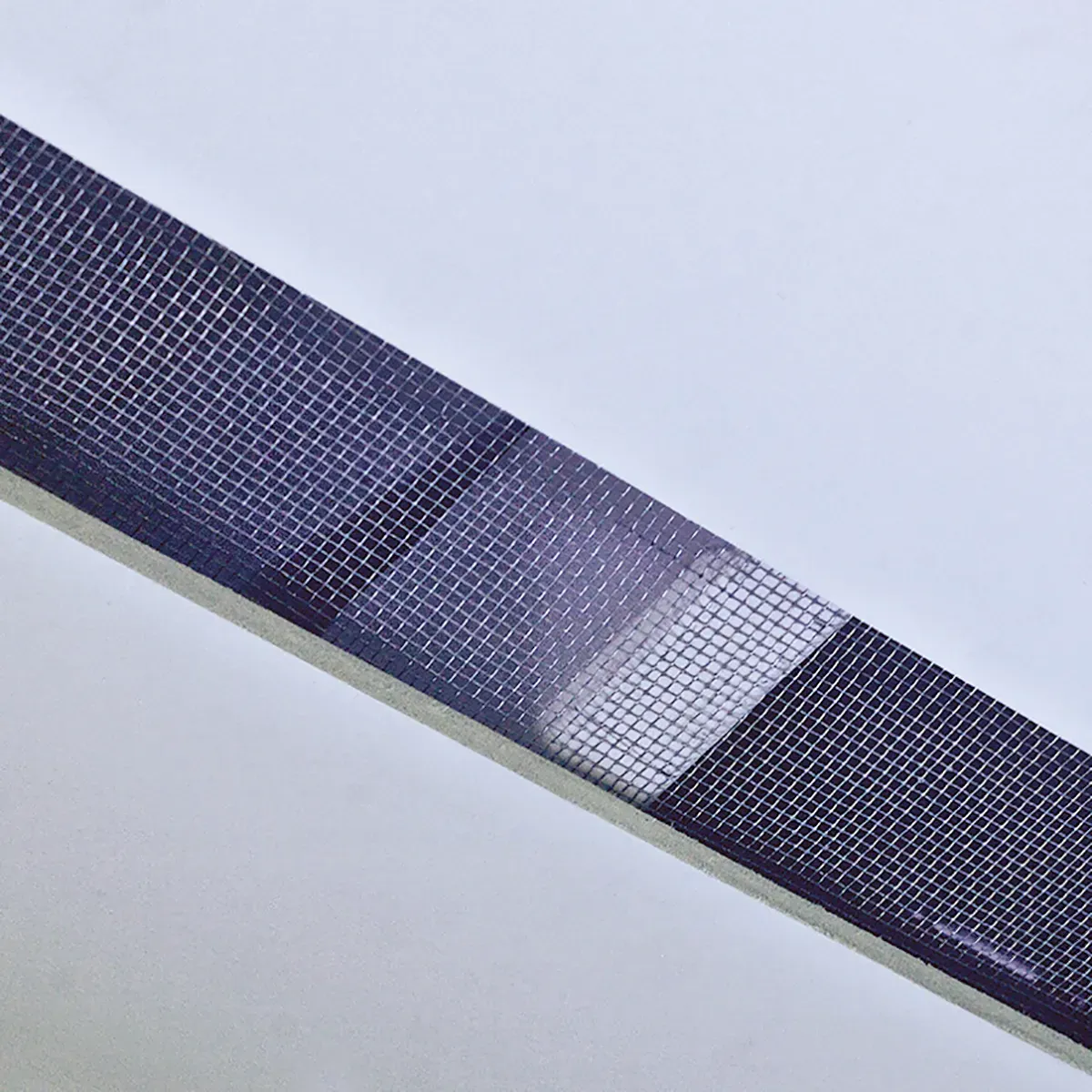

How to Improve the Durability of Square Metal Mesh in the Field of Industrial Equipment Protection?

Jan . 13, 2025 15:13

The durability of square metal mesh in the field of industrial equipment protection depends on its material, design and maintenance. Using high strength, stainless steel or galvanized steel wire can effectively improve its corrosion resistance and oxidation resistance and prolong its service life, especially in wet or chemically corrosive environment. In addition, regular inspection and maintenance of square metal mesh, such as removing dust, checking the firmness of connection points, and dealing with damaged parts in time, are also helpful to maintain the high efficiency and long-term use of square metal mesh. In the protection of industrial equipment, square metal mesh with strong durability can effectively avoid operation accidents, protect workers' safety and ensure the normal operation of equipment.

Choose the Square Metal Mesh from the Material Aspect

Selection of suitable metal materials: Select the material of metal mesh according to the characteristics of industrial environment. In corrosive chemical environment, square metal mesh made of stainless steel (such as 316 and 316L stainless steel) is preferred. 316 stainless steel contains molybdenum, which has better corrosion resistance and can withstand the corrosion of most acidic and alkaline chemicals. In the general machining workshop and other environments, the metal mesh made of carbon steel can meet the demand if it is properly anticorrosive, and the cost is relatively low.

Application of Surface Protective Coating on Square Metal Mesh

Anticorrosive coating: anticorrosive paint or other anticorrosive coatings can be coated on the surface of square metal mesh. For example, epoxy zinc-rich primer is a commonly used anticorrosive coating, which contains a lot of zinc powder, which plays the role of sacrificial anode in the coating. When the surface of metal mesh is corroded, the zinc powder is corroded first, thus protecting the square metal net matrix.

Wear-resistant coating: Wear-resistant coating can be used for metal mesh which is easy to be mechanically worn, such as square metal net used around material conveying equipment. Ceramic coating is a kind of coating with good wear resistance. It is a hard wear-resistant layer formed by mixing ceramic particles with binder and coating it on the surface of square metal net. This coating can effectively reduce the friction and wear of materials on the metal mesh and prolong the service life of the metal mesh.

Reasonable Installation and Maintenance of Square Metal Mesh

Correct installation: When installing the square metal mesh, make sure it is installed firmly. Use suitable installation fittings, such as high-strength bolts, nuts and washers, to fix the square mesh around the equipment or on the protective frame. For protective occasions that need to bear a large impact force, such as the metal mesh fence under the running track or near the forklift operation area, the metal mesh can be welded on the solid steel structure frame to enhance its impact resistance. At the same time, attention should be paid to avoid excessive stretching or twisting of the metal mesh during installation, so as not to cause damage to the metal wire.

Regular maintenance inspection: establish a regular maintenance inspection system. Check the surface condition of the square mesh regularly to see if there are any signs of corrosion, wear, deformation or damage. For the small area corrosion spots found, it can be repaired by sandpaper and then coated with anticorrosive paint. If it is found that the wire is broken or the mesh is seriously deformed, the damaged part should be replaced in time. At the same time, check whether the fixed parts of the metal mesh are loose. If they are loose, tighten the bolts or weld again in time.

Optimize the Use Environment of Square Metal Mesh

Environmental control: try to improve the use environment of metal mesh and reduce its exposure to harsh conditions. For example, in humid environment, the air humidity can be reduced by installing dehumidification equipment, thus slowing down the corrosion rate of metal mesh. In the environment with dust, installing effective ventilation and dust removal system can not only reduce the harm of dust to equipment, but also reduce the wear and blockage of metal mesh by dust.

Avoid excessive use and abuse: during the operation of the equipment, it is necessary to avoid unnecessary external impact and friction on the metal mesh. For example, in the process of equipment maintenance or material handling, attention should be paid to protecting the square mesh to prevent tools, equipment or materials from directly colliding with the metal mesh.