industrial chain link fence parts

Dec . 03, 2024 18:07

Understanding the Industrial Chain Link Fence Parts

Chain link fences have become an essential part of security and enclosure solutions used in various settings, including residential, commercial, and industrial areas. The efficiency and durability of a chain link fence are largely attributed to its individual parts, each serving a specific function. Understanding these components is crucial for both installation and maintenance. This article will explore the key parts of an industrial chain link fence and the role they play in the overall system.

1. Chain Link Fabric

The chain link fabric is the primary component of the fence, typically composed of galvanized steel wires twisted together to form a diamond-shaped mesh. This mesh is available in various heights, gauges (thickness), and coatings (such as vinyl or powder coating) to fit different aesthetic and functional needs. The fabric is durable and resistant to weather conditions, making it suitable for long-term use.

2. Fence Posts

Posts act as the backbone of the chain link fence structure, providing support and stability. There are three main types of posts terminal posts, line posts, and corner posts.

- Terminal Posts Installed at the beginning and end of a fence line, these posts anchor the fence and provide termination points. - Line Posts Positioned between terminal posts, line posts support the chain link fabric and maintain the vertical alignment of the fence. - Corner Posts Used at corners, these posts are specially designed to withstand greater tension and provide strength to the fence’s structure.

3. Post Caps

Post caps are installed at the top of fence posts to prevent water accumulation and rust, thus prolonging the life of the fence. They are available in various styles, such as flat or pointed, and can enhance the aesthetic appeal of the fence.

4. Top Rail

The top rail is a horizontal component that runs along the top of the fence, connecting the posts. It provides structural integrity and adds to the overall robustness of the fence. The top rail also helps keep the chain link fabric taut, preventing sagging and potential damage.

industrial chain link fence parts

5. Tension Wire

Tension wire is often used at the base of the fence or along its top, providing additional support to the chain link fabric. This wire maintains the fabric's tension and alignment, preventing it from bending or sagging over time. Tension wire is usually composed of the same material as the chain link fabric for uniformity and strength.

6. Brace Bands and Tension Bands

Brace bands are metal bands that connect the chain link fabric to the terminal posts, while tension bands are used to attach the fabric to both terminal and line posts. These bands ensure that the fabric remains securely in place and can withstand external pressures, such as wind or impacts.

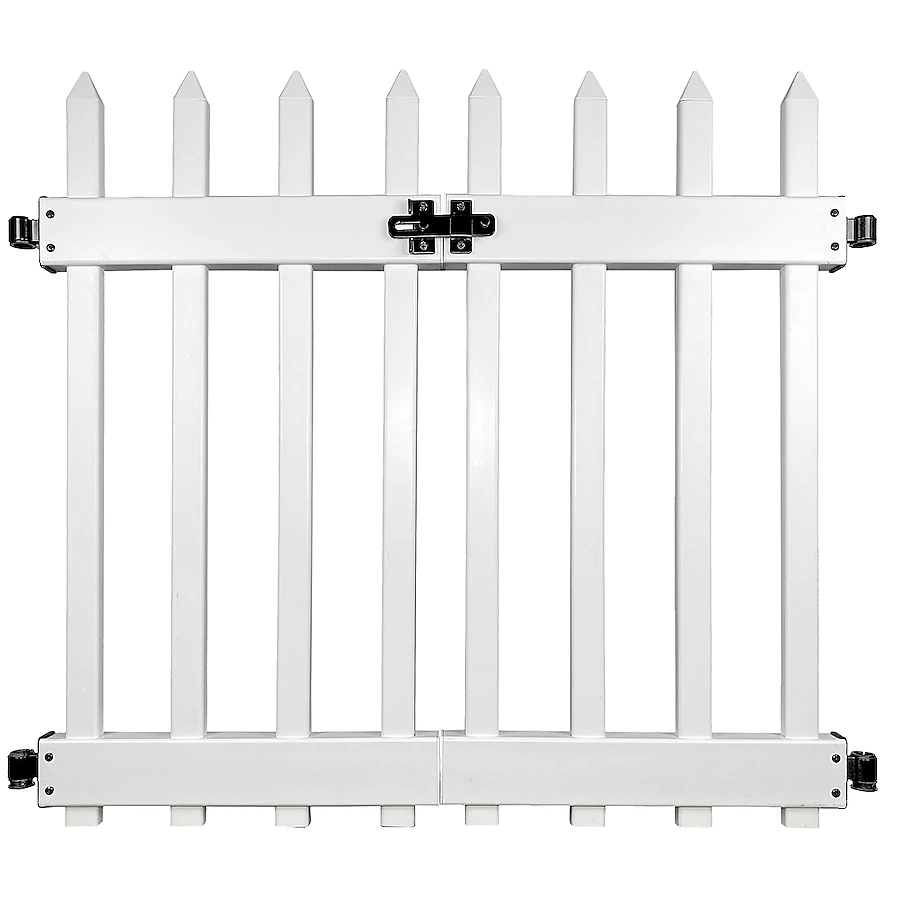

7. Gates

No fence is complete without gates, which provide access points to the enclosed area. Gates can be swinging or sliding and are available in various styles to complement the chain link fabric. Constructed with durable materials and equipped with secure locking mechanisms, gates enhance both functionality and security.

8. Fittings and Accessories

To ensure the proper installation and functioning of chain link fences, various fittings and accessories are required. This includes fasteners, hinges, latches, and brackets. These components not only help in assembling the fence but also aid in maintaining its structural integrity.

Conclusion

Understanding the individual parts of an industrial chain link fence is crucial for selecting the right materials, ensuring proper installation, and executing necessary maintenance. Each component contributes to the fence's overall performance, durability, and aesthetic appeal. Whether for securing a commercial property, demarcating boundaries in industrial settings, or providing safety in residential areas, the quality and arrangement of these parts are vital. Investing in high-quality materials and ensuring proper installation will ultimately lead to a reliable and effective fencing solution that meets specific needs.