Machine Guarding Fences and Employee Training: Creating a Safe Work Environment

Dec . 12, 2024 09:54

In industrial environments, where heavy machinery and complex systems are in constant operation, safety is a paramount concern. One of the most effective ways to protect workers from machinery hazards is through the use of machine-guarding fences. These fences serve as physical barriers, preventing workers from coming into contact with moving parts or dangerous equipment. However, the installation of machine-guarding fences alone is not sufficient to ensure safety in the workplace. Employee training plays a crucial role in maximizing the effectiveness of these safety systems. Together, machine-guarding fences and comprehensive employee training create a safer, more efficient work environment.

The Importance of Machine Guarding Fences

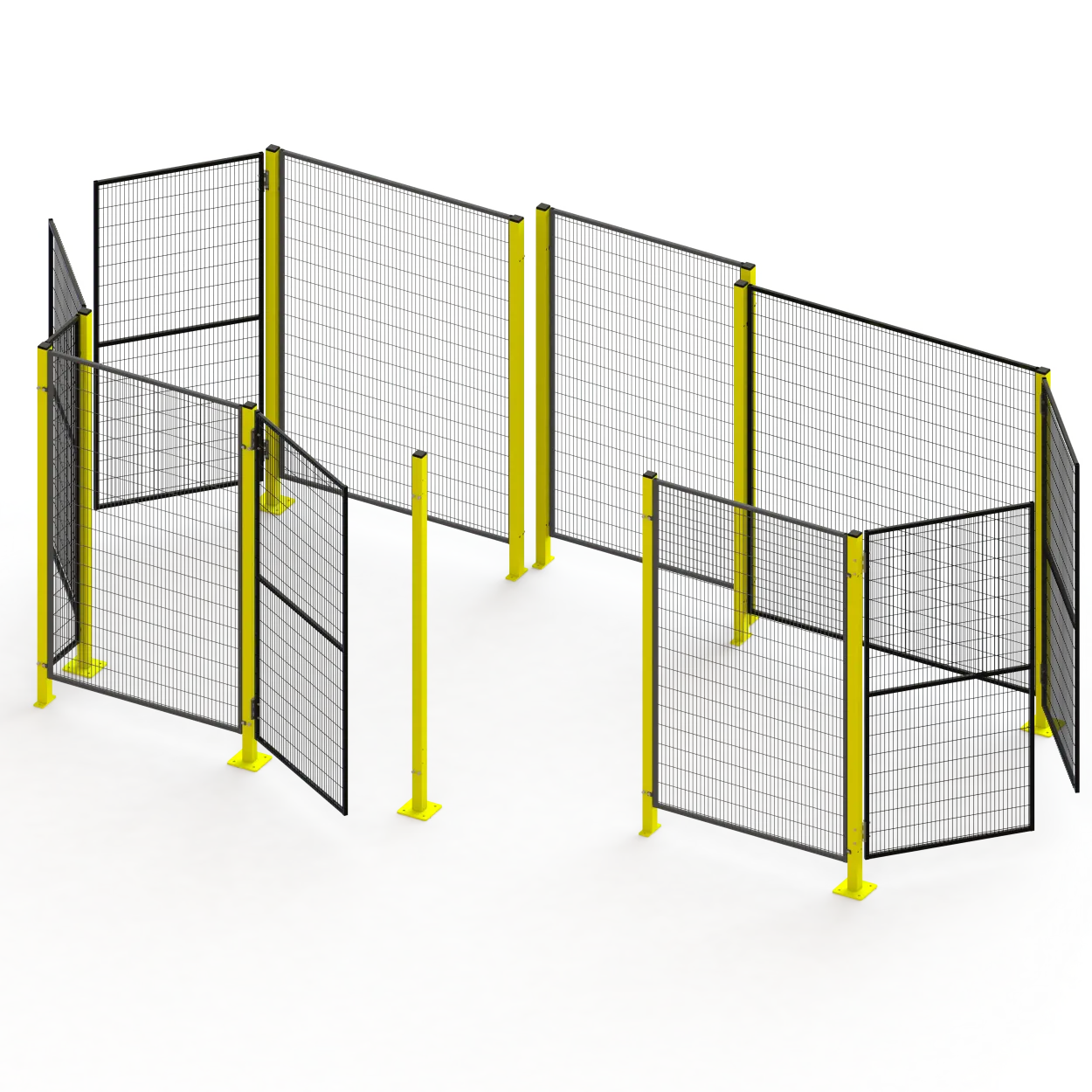

Machine guarding fences are physical barriers designed to protect workers from the dangers posed by machinery in operation. These fences typically enclose dangerous machine parts, preventing accidental contact with moving components, such as belts, gears, and cutting tools. In industries where equipment is powerful and high-speed, machine-guarding fences act as a critical line of defense.

By creating physical separation between workers and machines, these fences reduce the likelihood of accidents such as entanglement, impact injuries, and exposure to flying debris. Not only do machine-guarding fences enhance safety, but they also help organizations comply with safety regulations set forth by governing bodies like OSHA (Occupational Safety and Health Administration). OSHA mandates the use of proper guarding to prevent injuries caused by mechanical hazards.

There are several types of machine guarding fences available, including welded wire mesh fences, solid panels, and perimeter guarding systems. The type of fence chosen depends on factors such as the nature of the machinery, the size of the workspace, and the level of visibility required for operators. Regardless of the specific type, all machine-guarding fences aim to create a safer environment for workers by reducing the risk of accidents.

Employee Training: The Key to Effective Machine Fencing System

While machine guarding fences are essential for preventing accidents, they cannot fully protect workers unless employees are properly trained in their use and in overall machine safety procedures. Employee training should focus on two main areas: understanding how to interact with the machine guarding system and recognizing the importance of following safety protocols.

1. Understanding Machine Guarding Fences

Training employees on the specific types of machine-guarding fences used in the workplace is crucial. Workers should understand the purpose of the fencing and why it’s in place. They should also be aware of the hazards that exist if the fence is removed, bypassed, or tampered with. Employees must know when and how to approach machines safely, ensuring they never enter the guarded area while the equipment is in operation.

One key aspect of machine guarding training is teaching employees the proper use of emergency stops and safety interlocks, which are often integrated into the fencing system. These mechanisms ensure that if a worker enters a guarded area or if there is an unexpected safety risk, the machine will automatically shut down to prevent injury.

2. Proper Interaction with Machinery

Training employees to interact safely with machinery involves teaching them not only the mechanics of how the machine operates but also how to use the machine safety fencing as part of their workflow. Employees should be educated on the importance of never bypassing or altering the safety features of the guarding system. This includes not trying to open or dismantle fences without proper authorization and understanding the dangers of working in unguarded areas.

Moreover, workers should be trained on the procedures for safely cleaning, maintaining, and setting up machines while ensuring that the guarding systems are intact. This is particularly important in manufacturing environments where workers might need to perform maintenance or make adjustments to machinery. Ensuring that machines are de-energized and the guards are properly positioned before maintenance begins is a crucial part of this training.

3. Recognizing Safety Hazards

Training employees to recognize hazards is equally important. While machine-guarding fences are designed to mitigate risks, they are not foolproof. Workers need to be trained to identify when a guard is not functioning properly or when there are gaps in protection. For example, a fence may become damaged during routine machine operation or maintenance, and workers should know the proper procedures for reporting these issues immediately.

Employees should also be taught to understand the different types of hazards present in the workplace, including mechanical, electrical, and environmental risks. By fostering a safety-conscious mindset, workers will be more likely to spot hazards before they become a serious issue. Regular safety inspections and ongoing training are essential to keeping workers informed about potential dangers.

Integrating Employee Training with Machine Guarding Fences

When machine guarding fences and employee training are integrated effectively, the results are profound. An environment that prioritizes safety will not only reduce accidents and injuries but will also improve overall productivity. Here are some best practices for integrating employee training with machine guarding systems:

1. Ongoing Safety Education

Safety education should not be a one-time event. Employees need ongoing training to stay updated on new safety practices, regulations, and equipment. This includes refresher courses, as well as training on new machines or updated guarding systems. Engaging employees in regular safety drills ensures that everyone knows what to do in case of an emergency.

2. Clear Communication and Reporting Systems

A vital aspect of training is teaching workers how to communicate safety concerns effectively. Employees should be encouraged to report any issues with machine guarding fence panels immediately. Clear communication channels, such as designated safety officers or regular safety meetings, can help ensure that potential hazards are addressed before they lead to accidents.

3. Collaboration Between Operators and Maintenance Teams

Collaboration between machine operators and maintenance personnel is essential to maintaining a safe work environment. Operators should be trained to work closely with maintenance teams to ensure that machine-guarding fences are regularly inspected, repaired, and replaced as necessary. This collaboration helps ensure that safety features are never compromised.

Machine guarding fences and employee training are integral parts of a robust workplace safety program. While the physical barriers provided by machine guarding fences significantly reduce the risks associated with machinery, it is the training of employees that makes these safety systems effective. Through comprehensive training programs, employees learn how to properly interact with machines, recognize hazards, and understand the importance of adhering to safety protocols. When these elements are combined, they help create a work environment that minimizes risks and maximizes safety, ensuring that workers can perform their tasks without the threat of injury.