Premium Square Mesh & Welded Wire Mesh Solutions

Aug . 15, 2025 01:00

Unveiling Square Mesh: An Essential Component in Industrial Applications

In the intricate world of industrial filtration, separation, and reinforcement, square mesh stands out as a foundational material. Renowned for its uniform aperture, robust construction, and versatile applications, this product is critical across numerous sectors from civil engineering to advanced manufacturing. Its precise geometric design ensures consistent performance, making it indispensable for critical processes where material integrity and filtration efficiency are paramount. Understanding its nuanced properties and manufacturing excellence is key for B2B decision-makers seeking reliable, high-performance solutions.

This comprehensive guide delves into the technical specifications, manufacturing processes, and diverse applications of this essential component. We will explore how advancements in materials science and fabrication techniques contribute to the superior performance and extended service life of modern square mesh products. Furthermore, we will address common challenges and highlight the inherent advantages of selecting a reputable manufacturer committed to stringent quality controls and responsive customer support, ensuring that your investment yields optimal long-term value and operational efficiency.

The Engineering Behind Square Mesh: Materials and Manufacturing

The production of high-quality square mesh involves a sophisticated sequence of processes, starting with the selection of premium raw materials. Typically, materials such as stainless steel (304, 316, 316L grades), galvanized steel, plain steel, and even some specialized alloys are utilized, each chosen for its specific properties like corrosion resistance, tensile strength, and ductility. For instance, AISI 304 stainless steel is widely preferred for its excellent balance of corrosion resistance and strength, making it suitable for general industrial applications, whereas 316L stainless steel offers superior resistance to pitting and crevice corrosion in chloride-rich environments, crucial for marine or chemical processing sectors.

The core manufacturing processes for square wire mesh often include precision wire drawing, weaving, or welding. Wire drawing reduces the wire diameter to precise specifications, enhancing its tensile properties. Following this, the wires are either woven on specialized looms to create an interlocking pattern, forming woven square wire net, or resistance-welded at each intersection to produce rigid welded square mesh. Each method offers distinct advantages; woven mesh provides flexibility and excellent filtration, while welded mesh delivers superior rigidity and structural integrity, often used for security fencing or concrete reinforcement. Post-production treatments, such as hot-dip galvanizing or PVC coating, are applied to enhance corrosion resistance and extend product life, significantly contributing to the product's performance in challenging conditions.

Figure 1: Illustration of a typical square mesh weaving machine, ensuring precise aperture and uniform structure.

Rigorous quality control measures are integrated throughout the entire production lifecycle. This includes material composition verification, precise aperture size measurement (to ISO 9044 or ASTM E2016 standards), and tensile strength testing. Manufacturers often adhere to international standards such as ISO 9001 for quality management systems and specific product standards like ANSI/AWWA C203 for lining of steel water pipelines, or various ASTM standards for material specifications. These stringent checks ensure that the final product meets specified technical parameters, possesses a predictable service life, and performs optimally in demanding industrial environments, including petrochemical, metallurgy, mining, and water treatment applications where robust and corrosion-resistant solutions are critical. The average service life for high-grade stainless steel square mesh can exceed 20 years under proper conditions, showcasing its long-term cost-effectiveness.

Key Technical Parameters and Specifications

Selecting the appropriate square mesh requires a thorough understanding of its key technical parameters. These specifications directly impact performance, filtration efficiency, and structural integrity in various applications. The most critical parameters include the mesh count, wire diameter, aperture size, material grade, and surface treatment. Mesh count refers to the number of openings per linear inch, directly correlating with the fineness of filtration. Wire diameter defines the strength and durability of the mesh, while aperture size, or opening size, is the clear distance between adjacent parallel wires, determining the size of particles that can pass through.

For instance, a finer mesh count (e.g., 100 mesh) with a smaller wire diameter (e.g., 0.1mm) is ideal for precision filtration in chemical or pharmaceutical industries, achieving particle separation down to micron levels. Conversely, a coarser mesh (e.g., 4 mesh) with a larger wire diameter (e.g., 2.0mm) is more suited for heavy-duty screening, guarding, or reinforcement, common in construction or mining. The choice of material—such as SS304 for general use or SS316L for corrosive environments—is also paramount. Below is a table outlining common specifications for various square mesh types, providing a quick reference for procurement and engineering teams.

| Parameter | Description | Typical Range/Value | Common Material |

|---|---|---|---|

| Mesh Count | Openings per linear inch | 2 mesh to 635 mesh | All types |

| Wire Diameter | Thickness of individual wire | 0.02mm to 6.0mm | All types |

| Aperture Size | Clear opening between wires | 0.022mm to 12.0mm | All types |

| Standard Width | Standard roll/panel width | 0.914m to 2.0m (3ft to 6.5ft) | All types |

| Tensile Strength | Resistance to breaking under tension | Typical 550-690 MPa (Stainless Steel) | Stainless Steel, High Carbon Steel |

| Temperature Range | Operational temperature limits | -200°C to +800°C (Stainless Steel) | Stainless Steel |

Figure 2: Example of a durable welded square mesh panel, ideal for security and structural applications.

The interplay of these parameters dictates the mesh's suitability for specific tasks. For example, a small square chicken wire mesh, often made from galvanized steel with a relatively large aperture, is optimized for agricultural enclosures, balancing cost-effectiveness with animal containment. Conversely, a fine stainless steel square wire mesh might be used in laboratory sieves, requiring extremely precise and consistent aperture sizes for particle analysis. Our technical team is available to assist in specifying the optimal parameters for your unique operational requirements.

Diverse Applications and Key Advantages

The versatility of square mesh is evident in its widespread adoption across an impressive range of industries and applications. In the petrochemical sector, it is indispensable for filtration in distillation columns, catalyst support, and as protective screening for sensitive equipment due to its high temperature resistance and corrosion resilience. Metallurgical industries rely on it for screening ores, sizing aggregates, and as furnace screens, where its structural stability under extreme heat is critical. For water treatment and drainage systems, stainless steel square wire mesh serves as effective strainers, pre-filters, and support grids for filter media, preventing blockages and ensuring clean water flow, thereby enhancing operational efficiency and reducing maintenance costs.

Beyond these heavy industries, square mesh finds use in architectural design for facades and interior elements, in agriculture for animal enclosures and pest control, and in security applications as protective barriers and fencing. The choice between woven and welded square mesh often depends on the specific demands of the application. Woven mesh offers flexibility and finer filtration capabilities, making it suitable for vibrating screens or sieves where particle separation is crucial. Welded mesh, with its rigid structure, is preferred for applications requiring strong support, such as concrete reinforcement, machine guarding, or robust perimeter fencing, offering superior impact resistance and durability.

Figure 3: Square mesh utilized in a liquid filtration system, demonstrating its role in precise particle separation.

A key advantage of high-quality square mesh is its contribution to operational efficiency and cost savings. Its precise construction ensures consistent flow rates and optimal filtration, leading to reduced energy consumption in pumping and processing. Furthermore, the inherent corrosion resistance of stainless steel variants significantly extends service life, minimizing the need for frequent replacements and associated downtime, thereby offering a substantial return on investment. For example, in a critical wastewater treatment facility, the adoption of a corrosion-resistant square mesh screen might reduce replacement cycles from 2 years to 10 years, translating into significant labor and material savings over time. Its robust nature also provides superior protection against physical impact and wear, ensuring long-term reliability in demanding environments.

Choosing Your Partner: Manufacturer Comparison and Customization

In the competitive landscape of industrial suppliers, selecting the right manufacturer for your square mesh needs is crucial. A reputable manufacturer distinguishes itself not only by the quality of its products but also by its adherence to international standards, comprehensive technical support, and proven track record. Key differentiators include ISO 9001 certification, which signifies a robust quality management system, and specialized certifications relevant to specific industries such as FDA compliance for food-grade applications or CE marking for European markets. Manufacturers with extensive service histories, often spanning decades, possess invaluable expertise in diverse industrial challenges and can provide tailored solutions.

When comparing manufacturers, consider their capabilities in offering custom solutions. While standard sizes and specifications are readily available, many applications require bespoke designs. This might include specific mesh counts, unique wire diameters, non-standard dimensions, custom edge treatments (e.g., selvaged, welded, or cut edges), or specialized coatings for enhanced chemical resistance or aesthetic requirements. A manufacturer capable of rapid prototyping and delivering short-run custom orders demonstrates agility and a commitment to client-specific needs. For instance, a client in the automotive sector might require a specific mesh geometry for a component, demanding precise laser cutting and forming capabilities that go beyond standard production.

Figure 4: Examples of square mesh rolls showcasing various specifications and material finishes, ready for diverse industrial applications.

Our company prides itself on a legacy of over 20 years in delivering high-quality square mesh and related products, serving over 500 enterprise clients globally. Our manufacturing facilities are ISO 9001 certified, ensuring every product meets stringent international quality benchmarks. We conduct rigorous tensile strength, corrosion resistance, and dimensional accuracy tests on every batch, providing comprehensive test reports upon request. Our dedicated engineering team specializes in collaborating with clients to develop custom solutions, from unique aperture designs for specialized filtration to large-scale panels for architectural projects. Our commitment extends to timely delivery, with an average lead time of 2-4 weeks for standard orders and flexible scheduling for complex custom projects.

Ensuring Trust: Quality Assurance, Delivery, and Support

Trust is the cornerstone of B2B relationships, built on consistent product quality, transparent processes, and reliable support. Our commitment to trustworthiness is reflected in our comprehensive quality assurance protocols, which involve multi-stage inspections from raw material sourcing to final product packaging. Every batch of square mesh undergoes detailed checks for wire diameter consistency, mesh aperture uniformity, weld strength (for welded mesh), and surface finish. We utilize advanced optical inspection systems and precision calipers to ensure compliance with specified tolerances, providing clients with material test certificates and quality reports. Our products consistently exceed industry average performance benchmarks, delivering superior longevity and reliability in demanding operational environments.

Understanding the critical nature of project timelines, we have optimized our supply chain to ensure efficient delivery. For standard square mesh products, our typical delivery cycle is between 15 to 20 business days from order confirmation, depending on volume and customization. For highly specialized or large-volume orders, a more precise delivery schedule is provided after technical review. We offer various shipping options, including sea freight, air freight, and express courier services, to meet diverse logistical requirements and budgetary constraints. Each shipment is meticulously packaged to prevent damage during transit, ensuring your product arrives in pristine condition.

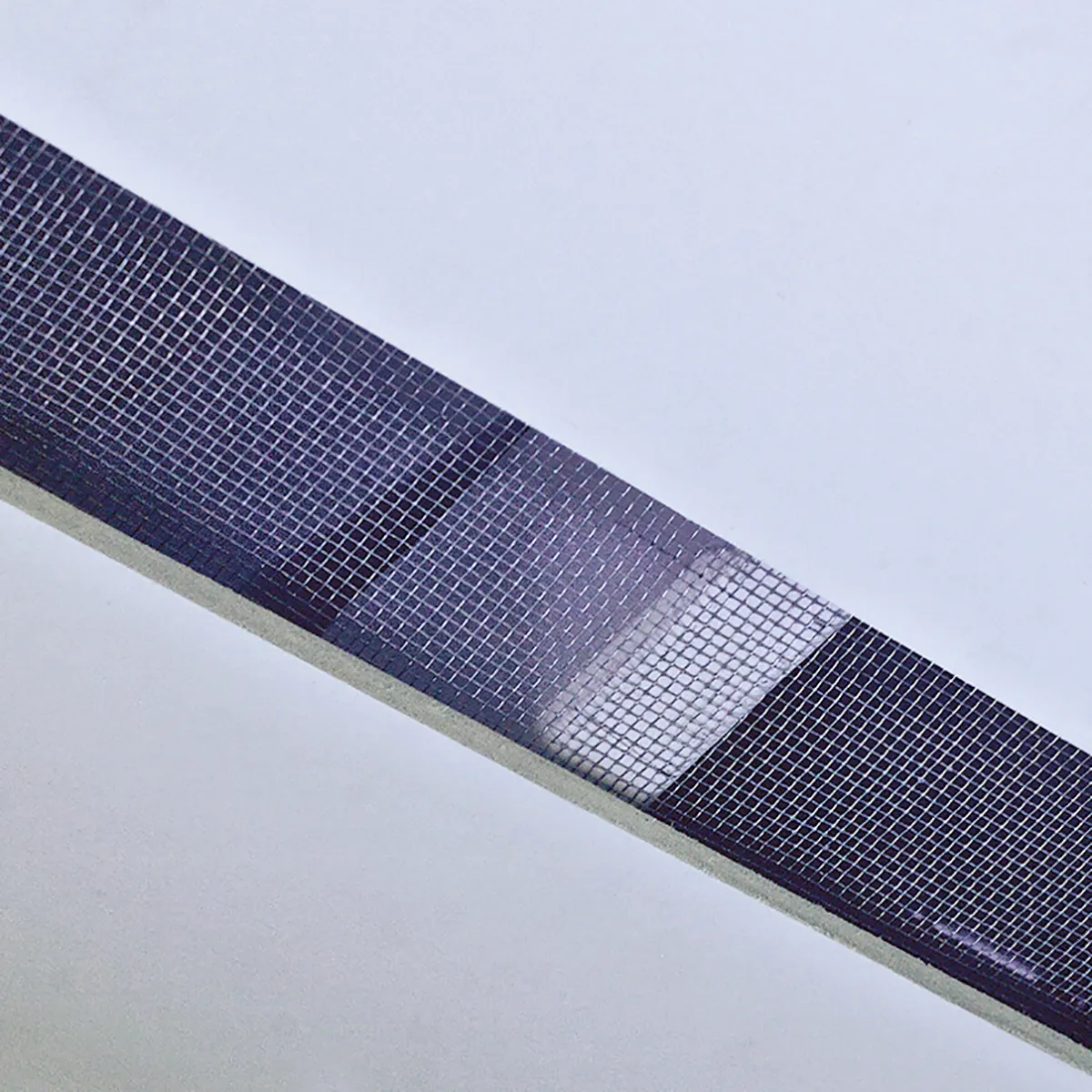

Figure 5: A close-up of high-precision square mesh, illustrating the consistent weave and robust construction that ensures optimal performance.

Our commitment does not end with delivery. We back our square mesh products with a comprehensive warranty against manufacturing defects, typically ranging from 1 to 5 years depending on the product type and application. Our dedicated customer support team is available to assist with any post-purchase inquiries, technical troubleshooting, or reorder processing. We offer responsive communication channels, including email, phone, and online chat, ensuring that expert advice and support are always within reach. This holistic approach to product quality, logistical efficiency, and ongoing client support reinforces our position as a trusted partner in the industrial mesh market.

Frequently Asked Questions (FAQ)

-

Q1: What is the difference between woven and welded square mesh?

Woven square mesh is produced by interlacing individual wires, similar to fabric, offering flexibility and suitability for filtration applications. Welded square mesh, conversely, has wires resistance-welded at each intersection, creating a rigid structure ideal for fencing, guarding, and concrete reinforcement due to its superior strength and stability. The choice depends on the application's specific requirements for flexibility, strength, and filtration precision.

-

Q2: How do I determine the correct mesh count and wire diameter for my application?

Determining the correct specifications depends on the desired particle size separation (aperture), the required strength, and the operating environment. Finer mesh counts are for smaller particles, while larger wire diameters provide greater strength. Our technical sales team can provide guidance based on your specific filtration, screening, or structural support needs, considering factors like material type, flow rate, pressure, and corrosion exposure. We often recommend a detailed consultation to ensure optimal product selection.

-

Q3: What materials are commonly used for square mesh and why?

Common materials include stainless steel (grades 304, 316, 316L), galvanized steel, and plain carbon steel. Stainless steel is chosen for its excellent corrosion resistance, high temperature tolerance, and hygienic properties, making it suitable for food processing, chemical, and marine environments. Galvanized steel offers good corrosion resistance at a lower cost, often used for outdoor applications like fencing. Plain carbon steel is economical for non-corrosive or less demanding applications.

-

Q4: Can square mesh be customized to specific dimensions or requirements?

Absolutely. We specialize in providing custom square mesh solutions. This includes non-standard widths and lengths, specific wire diameters, precise aperture sizes, unique edge finishes (e.g., U-bending, cut-to-size panels), and specialized coatings or treatments for enhanced performance in extreme conditions. Our engineering team works closely with clients to design and manufacture mesh products that precisely match their unique project specifications and operational demands, ensuring a perfect fit and optimal functionality for their specialized needs.

Conclusion

The pervasive utility and technical sophistication of square mesh underscore its critical role across a myriad of industrial applications. From the precision filtration requirements of the pharmaceutical sector to the robust reinforcement demands of civil engineering, its adaptable nature, coupled with advancements in material science and manufacturing precision, ensures its continued indispensable presence. By understanding the intricate details of its production, the nuances of its technical parameters, and the strategic advantages it offers in terms of efficiency and longevity, B2B stakeholders can make informed procurement decisions that translate into tangible operational benefits and long-term value.

Choosing a partner that exemplifies expertise, experience, authoritativeness, and trustworthiness is paramount. A manufacturer committed to stringent quality control, offering flexible customization, and providing comprehensive after-sales support guarantees not just a product, but a reliable solution. As industries evolve and demand for high-performance materials grows, the role of premium square mesh will only become more pronounced, solidifying its status as an essential component in the modern industrial landscape. Our commitment is to deliver solutions that not only meet but exceed these evolving demands, empowering our clients to achieve their operational objectives with confidence.

References

- ASTM E2016. Standard Specification for Industrial Woven Wire Cloth. ASTM International.

- ISO 9044. Industrial Woven Wire Cloth - Technical Requirements and Inspection. International Organization for Standardization.

- ASM Handbook, Volume 1. Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

- Corrosion Handbook. Shreir's Corrosion. Elsevier.

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy