Trusted Wire Mesh Decking Manufacturers | Strong, Safe Racking

Aug . 16, 2025 01:40

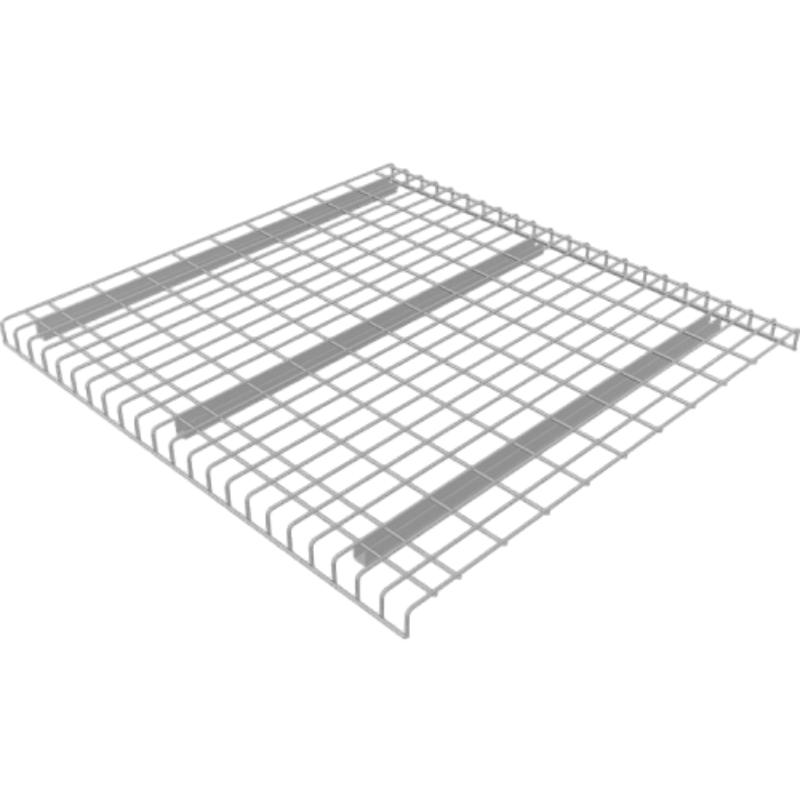

Understanding Wire Mesh Decking in Modern Warehousing

In the dynamic landscape of modern logistics and storage, the efficiency and safety of warehousing operations are paramount. Pallet racking systems form the backbone of these operations, and an essential component enhancing their functionality is wire mesh decking. This critical element significantly improves the safety, visibility, and cleanliness of stored goods, making it an indispensable asset for businesses across various sectors. As wire mesh decking manufacturers innovate, these products are evolving to meet increasingly stringent industry demands for strength, durability, and versatility. The transition from traditional wood or solid steel decking to wire mesh is driven by compelling advantages, including enhanced sprinkler penetration, reduced dust accumulation, and superior load-bearing capabilities. This shift underscores a broader industry trend towards smarter, safer, and more adaptable storage solutions that can cater to diverse product types and operational needs, from fast-moving consumer goods to heavy industrial components. The selection of the right wire mesh decking is a strategic decision that directly impacts operational efficiency and long-term cost savings within any modern distribution center or warehouse.

The demand for robust and reliable wire mesh decking continues to surge as businesses scale their storage capacities and optimize their inventory management systems. Beyond mere compliance with fire safety regulations, modern pallet rack wire decking offers improved ventilation, preventing moisture buildup and extending the shelf life of temperature-sensitive goods. Its open design ensures excellent light penetration, reducing the need for extensive artificial lighting within rack aisles and contributing to energy savings. Furthermore, the robust construction provides an additional layer of safety by preventing small items from falling through racks, a common hazard with beam-only systems. Manufacturers are constantly refining designs, offering various styles like flared, step, and inverted step decks, each tailored for specific rack configurations and load requirements. This adaptability ensures that facilities can achieve optimal storage density and accessibility, whether handling standard pallets or irregularly shaped items. The continuous evolution of materials and fabrication techniques by leading wire mesh decking manufacturers ensures that these products remain at the forefront of storage innovation, supporting the complex logistical challenges of global supply chains.

The Precision Manufacturing of Wire Mesh Decking

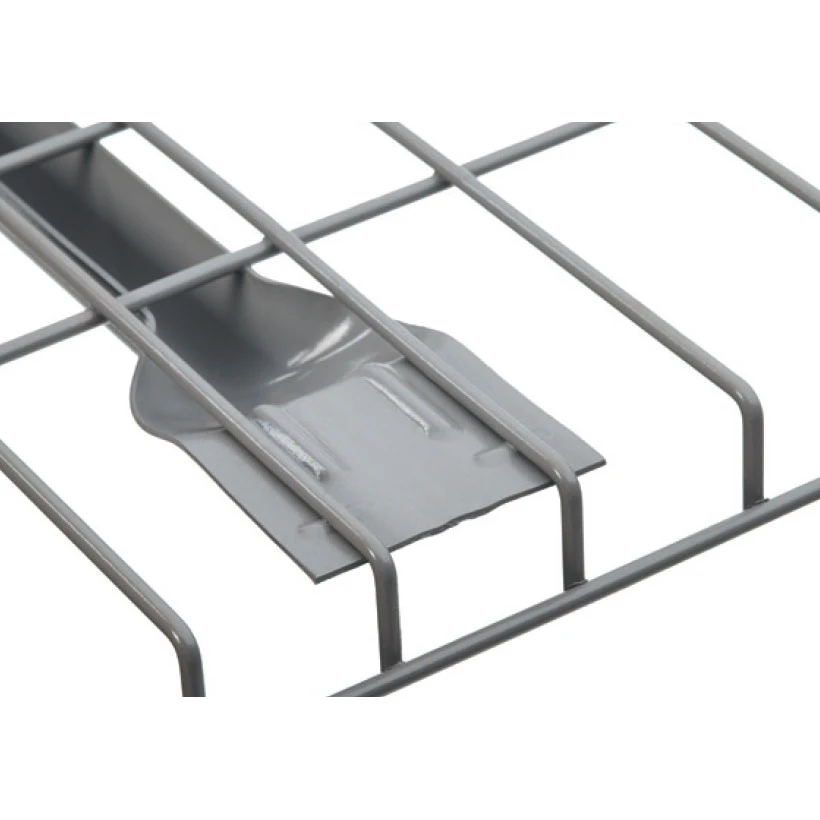

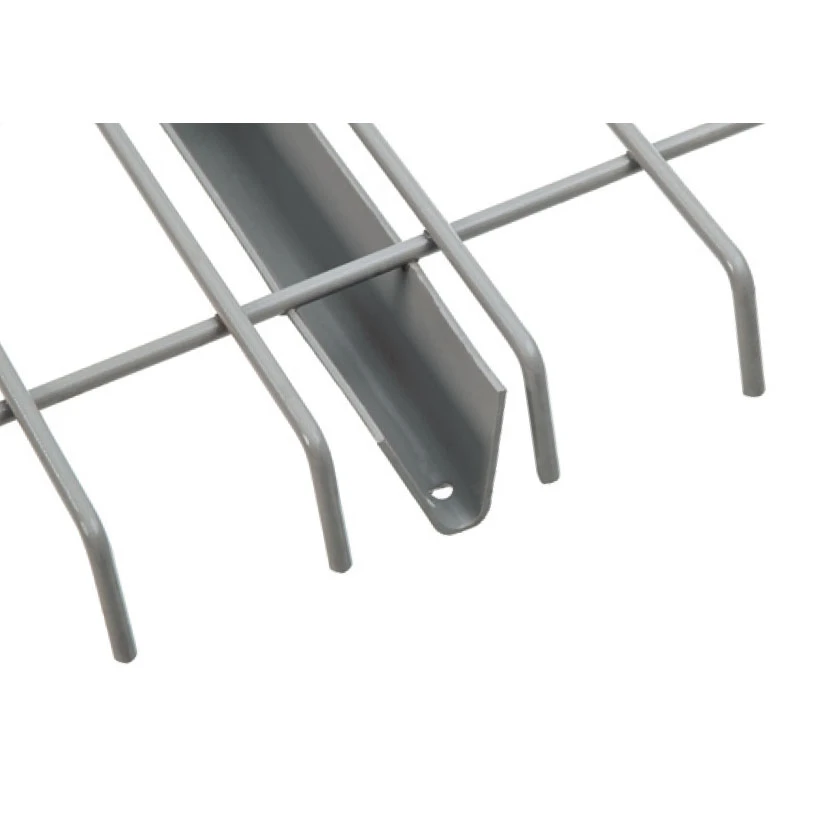

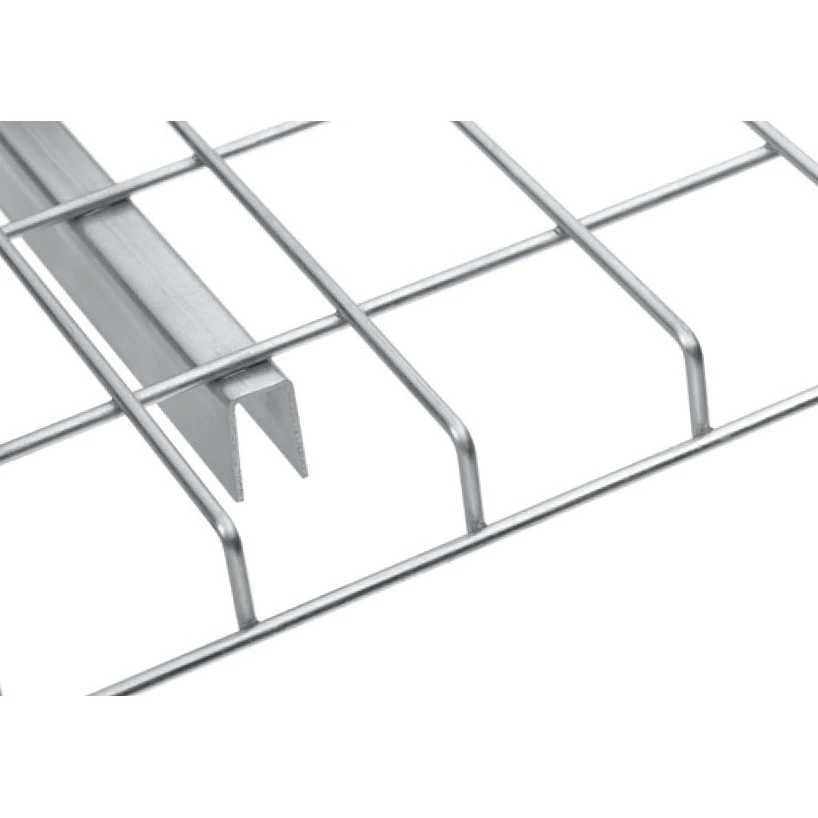

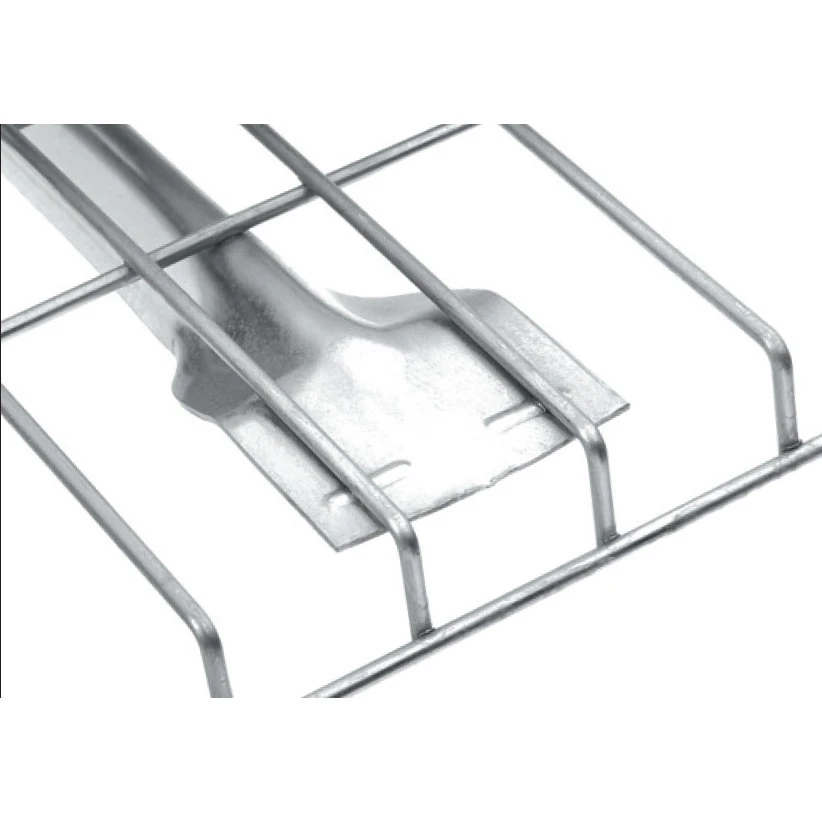

The production of high-quality wire mesh decking is a sophisticated process that demands precision engineering and adherence to stringent quality controls. Typically, the primary material used is high-grade carbon steel wire, often cold-drawn for superior tensile strength, although galvanized or stainless steel options are available for specific environments like those prone to corrosion in the petrochemical or food processing industries. The manufacturing journey begins with the wire being fed into automated welding machines that precisely fuse the longitudinal and transverse wires at every intersection. This resistance welding technique ensures robust, consistent welds that are critical for the structural integrity and load-bearing capacity of the decking. Following the welding, the formed mesh panels undergo various shaping processes, including cutting to size, bending the waterfall edges or flaring channels, and attaching support channels. These channels, often made from roll-formed or press-formed steel, are crucial for distributing the load evenly across the pallet rack beams. Each step is meticulously monitored to ensure dimensional accuracy and structural soundness, which is paramount for safety in a demanding warehouse environment.

Quality assurance is integrated at every stage of the manufacturing process to ensure that the final product meets or exceeds industry standards. Reputable wire mesh decking manufacturers typically implement rigorous testing protocols, including load capacity tests, weld strength evaluations, and corrosion resistance assessments for coated products. Compliance with international standards such as ANSI (American National Standards Institute) MH26.2 for wire mesh decking and various ISO certifications (e.g., ISO 9001 for quality management) is non-negotiable, providing assurance of product reliability and safety. Surface finishes, primarily powder coating or galvanization, are applied post-fabrication to enhance durability and corrosion resistance. Powder coating offers a resilient finish available in various colors for improved visibility and aesthetics, while galvanization provides superior protection against rust, particularly beneficial in high-humidity or outdoor applications. The estimated service life of well-maintained pallet rack wire decking can exceed 20 years, depending on environmental conditions and usage, making it a highly cost-effective long-term investment. Its inherent advantages, such as enhanced fire safety due to improved sprinkler penetration and superior load distribution, are critical in industries like metallurgy and general manufacturing where heavy loads and safety are top priorities.

Technical Specifications and Performance Metrics

Selecting the appropriate wire decking for racks requires a thorough understanding of key technical parameters that govern performance and safety. Critical specifications include wire gauge, mesh size, channel configuration, and crucially, load capacity. Wire gauge, typically ranging from 5 to 12 gauge, dictates the individual wire's thickness and directly impacts the decking's strength. Mesh size, commonly 2.5" x 4.5" or 2" x 4", refers to the spacing between the wires, influencing visibility, air circulation, and the support offered to smaller items. The design of the support channels is equally vital; waterfall, step, and inverted configurations cater to different beam types and loading methods, ensuring secure fitment and optimal weight distribution. Load capacity is expressed in pounds per square foot (PSF) or total uniformly distributed load (UDL) and is a function of all these parameters, as well as the quality of welds and materials. For instance, a common specification might be a UDL of 2,500 lbs to 3,000 lbs for standard pallet loads. This ensures the decking can safely support goods without deflection or structural fatigue, vital for preventing accidents and protecting inventory. Manufacturers provide detailed load charts based on extensive testing, often demonstrating capacities significantly higher than typical operational requirements to ensure a safety margin.

To aid in decision-making, below is a comparative table summarizing typical technical parameters and features offered by leading wire mesh decking manufacturers. This table highlights variations in specifications that can impact performance, cost, and suitability for specific applications. Understanding these nuances allows B2B buyers to make informed choices that align with their operational demands and budget constraints.

This table provides a general overview; specific load capacities and dimensions will vary by product line and manufacturer. Always verify specifications with the provider's official documentation and engineering data.

Versatile Applications and Industry Adoption

The adaptability of pallet wire decking makes it suitable for an expansive array of industries and applications, transcending conventional warehousing. Its inherent design benefits, such as fire safety compliance (meeting NFPA guidelines for sprinkler penetration), make it a preferred choice in sectors where strict safety codes are enforced, including retail, automotive, food and beverage, and pharmaceutical industries. In retail environments, wire mesh decking enhances product visibility and accessibility, supporting efficient picking operations. For the automotive industry, it safely stores heavy components and parts, with various capacities accommodating everything from small fasteners to engine blocks. The food and beverage sector benefits from improved hygiene, as the open mesh design prevents dust and debris accumulation and allows for easier cleaning and sanitation, a critical factor for FDA compliance. Furthermore, its robust construction and high load capacity are invaluable in manufacturing facilities, securely supporting raw materials, work-in-progress, and finished goods on various rack types, including selective, push-back, and drive-in systems. The ability to customize dimensions and load ratings ensures seamless integration into existing or newly designed storage systems, optimizing space utilization and operational flow.

Beyond traditional warehousing, wire mesh decking manufacturers also cater to specialized applications. For instance, in cold storage or freezer environments, galvanized wire mesh decking is preferred due to its superior corrosion resistance and ability to withstand extreme temperatures without degradation, ensuring long-term structural integrity. In contrast, standard powder-coated decking might be sufficient for ambient warehouse settings. The open mesh also minimizes condensation buildup, protecting goods from moisture damage. For pick modules and multi-level mezzanines, lighter gauge wire mesh offers visibility and fall protection while remaining cost-effective. Recent industry trends indicate a growing adoption of wire mesh decking in e-commerce fulfillment centers, where rapid inventory turnover and flexible storage solutions are crucial. The transparent design facilitates quicker visual inventory checks and improves scanning accuracy. Our client testimonials often highlight improved safety records and reduced product damage since implementing our Decking solutions. A major logistics provider, for example, reported a 15% reduction in minor incidents related to falling merchandise within six months of upgrading their racks with our wire mesh decking, underscoring its tangible benefits in real-world scenarios.

Customization and Manufacturer Selection

One of the significant advantages offered by leading wire mesh decking manufacturers is the capability for extensive customization. While standard sizes are widely available to fit common pallet rack dimensions (e.g., 42" deep x 46" wide), specialized applications often require bespoke solutions. Customization options include varying depths and widths to match unique rack systems, specific load capacities for exceptionally heavy or light loads, and tailored mesh sizes to accommodate unusual product dimensions or regulatory requirements. Furthermore, manufacturers can provide different support channel designs (e.g., U-channels, flared channels, step channels) to ensure compatibility with diverse beam types, including structural, teardrop, and slotted beams. The choice of finish—powder-coated in custom colors, hot-dip galvanized for maximum corrosion resistance, or electro-zinc plated for a cleaner appearance—further allows businesses to align the decking with their operational environment and aesthetic preferences. Expert manufacturers work closely with clients, often employing CAD (Computer-Aided Design) software to develop precise engineering drawings and conduct load simulations, ensuring the custom solution performs exactly as required under specified conditions. This collaborative approach minimizes risks and optimizes the investment.

When choosing among wire mesh decking manufacturers, several critical factors should guide the decision-making process. Firstly, assess the manufacturer's experience and reputation; a long-standing history of successful projects and positive client feedback is a strong indicator of reliability. Secondly, scrutinize their quality control processes and certifications (e.g., ISO 9001, ANSI standards compliance), which directly reflect the safety and durability of their products. A manufacturer's commitment to quality ensures a lower total cost of ownership through extended product life and reduced maintenance. Thirdly, evaluate their capacity for customization and technical support; the ability to provide tailored solutions and expert advice throughout the project lifecycle is invaluable. Fourthly, consider their logistical capabilities, including lead times and delivery schedules, especially for large-scale projects. Our company, with over 15 years of dedicated service in the B2B sector, prides itself on exceptional product quality, adherence to international standards, and a robust support infrastructure designed to ensure seamless project execution. We have successfully supplied Decking solutions to a diverse clientele, from regional distributors to multinational corporations, demonstrating our expertise and commitment to customer satisfaction.

Frequently Asked Questions (FAQ)

Q1: What are the primary benefits of using wire mesh decking over traditional solid decking?

Wire mesh decking offers several key advantages. Its open grid design significantly improves fire safety by allowing sprinkler systems to penetrate efficiently to all levels, a critical factor for insurance compliance and employee safety. It also enhances air circulation, which helps prevent moisture buildup and extends the life of stored goods, particularly in temperature-controlled environments. Furthermore, it prevents dust and debris accumulation, making the warehouse cleaner and easier to maintain. Unlike wood decking, wire mesh is non-combustible and does not degrade, splinter, or become slippery, contributing to a safer work environment. It also offers better visibility of stored products from below, aiding inventory management and reducing light obstruction. These factors collectively contribute to a more efficient, safer, and cost-effective storage solution.

Q2: How do I determine the correct load capacity for my wire mesh decking needs?

Determining the correct load capacity involves assessing the maximum weight of the pallets and their contents that will be stored on each shelf. It is crucial to calculate the Uniformly Distributed Load (UDL) per shelf, ensuring that the selected decking's UDL capacity safely exceeds this value. Factors such as pallet size, potential impact loads from forklift operations, and the number of support channels on the decking also influence the required capacity. Reputable wire mesh decking manufacturers provide detailed load charts and often offer engineering assistance to help clients select the appropriate decking based on their specific application and safety factor requirements. It is always recommended to slightly overspec the load capacity to account for unforeseen circumstances and ensure long-term structural integrity.

Q3: What are the typical lead times for custom wire mesh decking orders?

Lead times for wire mesh decking can vary significantly based on the order volume, customization complexity, and the manufacturer's current production schedule. For standard sizes and finishes, lead times can range from 2 to 4 weeks. However, for highly customized solutions involving unique dimensions, specific finishes, or very large quantities, lead times may extend to 6-8 weeks or even longer. It is always advisable to communicate your project timeline upfront with the wire mesh decking manufacturers and obtain a clear delivery schedule. Planning well in advance, especially for large-scale warehouse installations or upgrades, is crucial to avoid delays in your operational readiness. We strive to maintain efficient production cycles and clear communication regarding delivery expectations.

Commitment to Quality, Warranty, and Support

As leading wire mesh decking manufacturers, our commitment extends beyond the manufacturing floor to encompass comprehensive customer support and robust warranty provisions. We stand by the quality and durability of our Decking products, offering a standard warranty that covers manufacturing defects and structural integrity under normal operating conditions. Our typical warranty period is 5 to 10 years, reflecting our confidence in the materials and craftsmanship. Delivery is managed through established logistics networks, ensuring products arrive safely and on schedule, even for large-scale international shipments. We prioritize secure packaging and efficient freight coordination to minimize transit damage and delays. For technical inquiries, installation guidance, or post-purchase support, our dedicated customer service team is readily available. This includes expert engineers who can provide detailed product specifications, assist with custom design requirements, and offer troubleshooting advice. Our approach is to build long-term partnerships, providing not just products but complete solutions that contribute to the operational success and safety of our clients' facilities.

Our support infrastructure includes comprehensive documentation, such as installation guides, load capacity charts, and maintenance recommendations, to ensure optimal performance and longevity of the wire mesh decking. We understand that seamless integration into existing racking systems is crucial, and our team provides pre-sales consultations to verify compatibility and recommend the most suitable decking style and dimensions. Post-sales, we remain accessible for any questions related to product performance or expansion planning. Our commitment to continuous improvement, informed by customer feedback and evolving industry standards, ensures that our products remain at the forefront of storage technology. Choosing a manufacturer that offers unwavering commitment to product quality, a transparent warranty, and responsive customer support significantly reduces operational risks and guarantees a superior return on investment for your storage infrastructure. We pride ourselves on the trustworthiness we've built over years of consistent, high-quality service and reliable product delivery to industries worldwide.

Conclusion and References

Wire mesh decking represents a vital component in modern warehouse and logistics systems, offering unparalleled safety, efficiency, and durability. The expertise and innovation of leading wire mesh decking manufacturers ensure that these products meet the evolving demands of diverse industries, from heavy manufacturing to e-commerce fulfillment. Through precision engineering, rigorous quality control, and a commitment to customization, manufacturers are delivering solutions that enhance operational safety, optimize space utilization, and provide long-term value. As businesses continue to streamline their supply chains and maximize storage efficiency, the strategic selection of high-quality wire mesh decking becomes increasingly critical. Its inherent advantages in fire safety, ventilation, and load distribution make it an indispensable investment for any enterprise seeking to build a robust, compliant, and future-proof storage infrastructure.

References

- National Fire Protection Association (NFPA) 13: Standard for the Installation of Sprinkler Systems.

- Material Handling Industry (MHI) Specification ANSI MH26.2-2017: Wire Mesh Container and Wire Mesh Decking.

- International Organization for Standardization (ISO) 9001: Quality Management Systems – Requirements.

- Rack Manufacturers Institute (RMI) Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks.

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy