Understanding Different Varieties of Trailer Leaf Springs for Optimal Performance

Oct . 09, 2024 06:43

Types of Trailer Leaf Springs

Trailer leaf springs are essential components used in the suspension systems of trailers, providing support and stability while ensuring a smooth ride. They are designed to absorb shock and maintain the alignment of the trailer under varying loads. Understanding the different types of trailer leaf springs can help trailer owners select the most appropriate options for their specific needs.

1. Multi-Leaf Springs

Multi-leaf springs are the most common type of leaf springs used in trailers. They consist of multiple layers of steel plates, which are stacked in a curved design. The flexibility and strength of the spring increase with the number of leaves, allowing them to better handle varying loads. Multi-leaf springs are known for their durability and ability to distribute weight evenly, making them ideal for heavier trailers.

The design of multi-leaf springs allows for a gradual flexing motion, which helps in reducing sudden jolts during travel. However, they can be more rigid compared to other types, which may affect ride comfort. Multi-leaf springs are often used in larger trailers, such as those used for commercial transport.

As the name suggests, mono-leaf springs consist of a single layer of steel. This simplicity in design offers several advantages, including lighter weight and lower manufacturing costs. Mono-leaf springs provide sufficient support for lighter trailers, such as small utility trailers or recreational vehicles.

One of the significant benefits of mono-leaf springs is their ability to flex uniformly. This uniformity can lead to a smoother ride since they accommodate road irregularities more effectively than multi-leaf springs. However, their load capacity is limited compared to multi-leaf springs, making them unsuitable for heavier applications.

3. Elliptical Springs

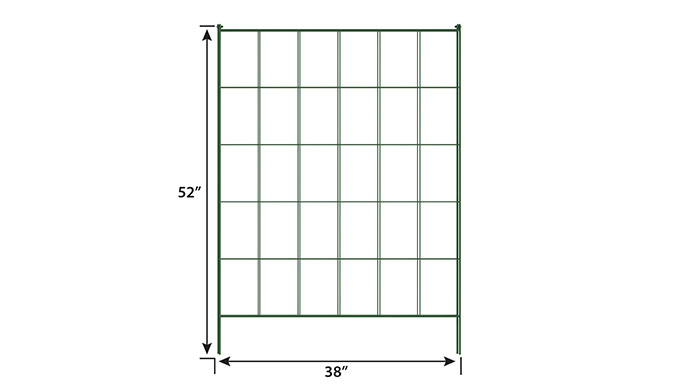

types of trailer leaf springs

Elliptical springs are another variant that offers a unique design. Unlike traditional leaf springs, elliptical springs feature a more curved shape that resembles the shape of an ellipse. This design allows for a greater degree of flex and weight distribution, improving the trailer's overall handling and ride quality.

Elliptical springs excel in off-road applications due to their ability to absorb impacts effectively. They provide superior shock absorption compared to standard leaf springs, making them a popular choice for trailers that frequent rough terrains. However, their complex design can make them more expensive to produce and maintain.

4. Tapered Leaf Springs

Tapered leaf springs are designed with varying widths along their length, which helps improve both flexibility and load-carrying capacity. These springs offer an efficient weight distribution system and help reduce unwanted lateral movement during travel.

Tapered leaf springs are often used in automotive applications, but they also find their place in certain trailer models. Their design allows for better ride quality and improved suspension performance, particularly under heavy loads.

Conclusion

The choice of trailer leaf springs can significantly affect a trailer's performance, safety, and overall ride quality. Multi-leaf springs provide excellent support for heavy loads but may compromise comfort for lighter trailers. Mono-leaf springs, while lighter and more cost-effective, are best suited for lighter applications. Elliptical and tapered leaf springs offer unique advantages for specific use cases, particularly in off-road conditions.

Ultimately, selecting the right type of leaf spring depends on the intended use of the trailer, the weight it will bear, and the desired balance between comfort and performance. Understanding these various types can guide trailer owners in making informed decisions that best fit their operational needs.