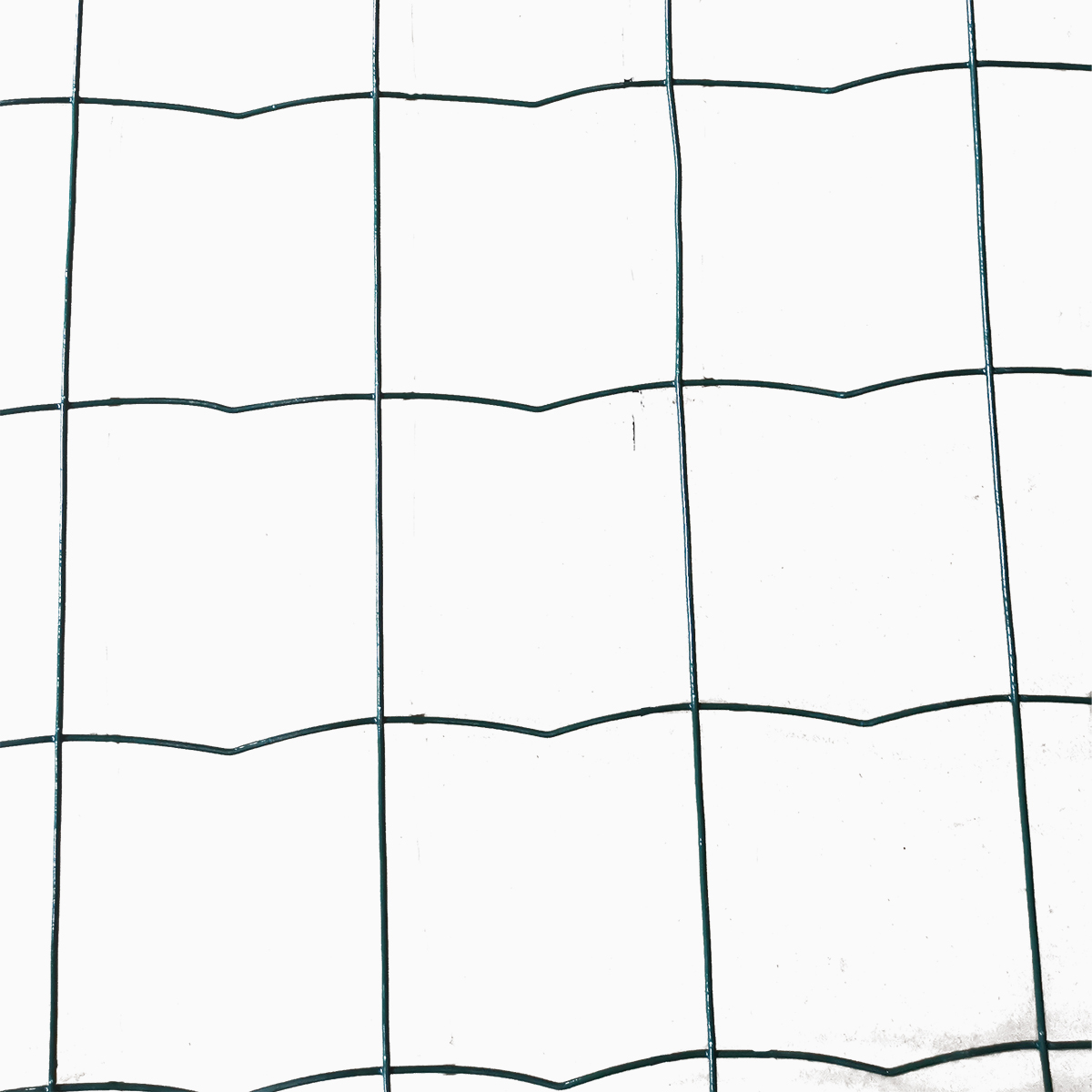

u type wire

Nov . 21, 2024 08:36

Understanding U-Type Wire Applications, Advantages, and Manufacturing

U-type wire, often referred to as U-bend wire or simply U-wire, is a versatile and commonly used component in various industries. Characterized by its U-shaped configuration, this wire product serves multiple purposes, ranging from construction to electronics and automotive applications. In this article, we will explore the unique features of U-type wire, its applications, advantages, and the manufacturing processes involved.

What is U-Type Wire?

U-type wire is typically made from materials such as steel, copper, or aluminum, which are chosen based on the intended application. The wire is bent into a U-shape, which allows for increased stability and strength compared to straight wire. This unique design also facilitates the wire's ability to support various loads, making it an ideal component in many structural applications.

Applications of U-Type Wire

U-type wire finds application across several industries due to its strength and versatility. Here are some notable uses

1. Construction In construction, U-type wire is often used as reinforcement for concrete structures. Its shape provides excellent support and helps in distributing loads evenly across the surface. This is critical in ensuring the longevity and durability of buildings and other infrastructures.

2. Electrical In the electrical sector, U-type wire is employed as a conductor in various devices. Its U-shape can accommodate quick connections and create stable electrical pathways, making it an essential component in wiring systems.

3. Automotive Within the automotive industry, U-type wire is often used for securing components and wiring harnesses. Its strength ensures that parts remain firmly attached even under high-stress conditions, such as driving over rough terrain or in extreme weather.

4. Agriculture U-type wire is also prevalent in agricultural settings, where it is used for supporting plants, such as vines and taller crops. The wire's robust nature allows it to withstand outdoor elements while providing necessary support.

Advantages of U-Type Wire

Several factors contribute to the growing popularity of U-type wire

u type wire

1. Strength and Durability The U-shape provides enhanced strength and durability compared to standard straight wire. This makes it suitable for heavy-duty applications where reliability is crucial.

2. Cost-Effective U-type wire is often available at a competitive price point, making it a cost-effective choice for both small-scale and large projects.

3. Customization Manufacturers can produce U-type wire in various dimensions, materials, and coatings, allowing for customization to meet specific project requirements.

4. Ease of Use The U-shape makes installation straightforward, whether it is being used in construction or other applications. The design simplifies connections and reduces the time needed for installation.

Manufacturing Processes

The production of U-type wire involves several steps

1. Material Selection The first step is to select the appropriate raw material based on the intended usage and required properties.

2. Wire Drawing The selected material is drawn into wire form, with the desired diameter achieved through a process of extrusion and stretching.

3. Bending After reaching the correct diameter, the wire is bent into a U-shape using specialized machinery. This step is crucial, as the bending process directly impacts the wire's strength and performance.

4. Finishing The final step involves finishing processes, which may include coating the wire for corrosion resistance, cutting it to specific lengths, or other treatments to enhance its properties.

Conclusion

U-type wire is an essential component across various industries, offering strength, durability, and versatility. Its unique shape allows it to perform in even the most demanding conditions, making it a reliable choice for engineers and manufacturers alike. As industries continue to evolve, the use of U-type wire will likely expand, driven by the ongoing need for robust and efficient materials in construction, electrical, automotive, and agricultural applications. Understanding its features and advantages can help businesses make informed decisions about incorporating U-type wire into their products and projects.