u type wire

Nov . 02, 2024 08:12

Understanding U-Type Wire Materials, Applications, and Benefits

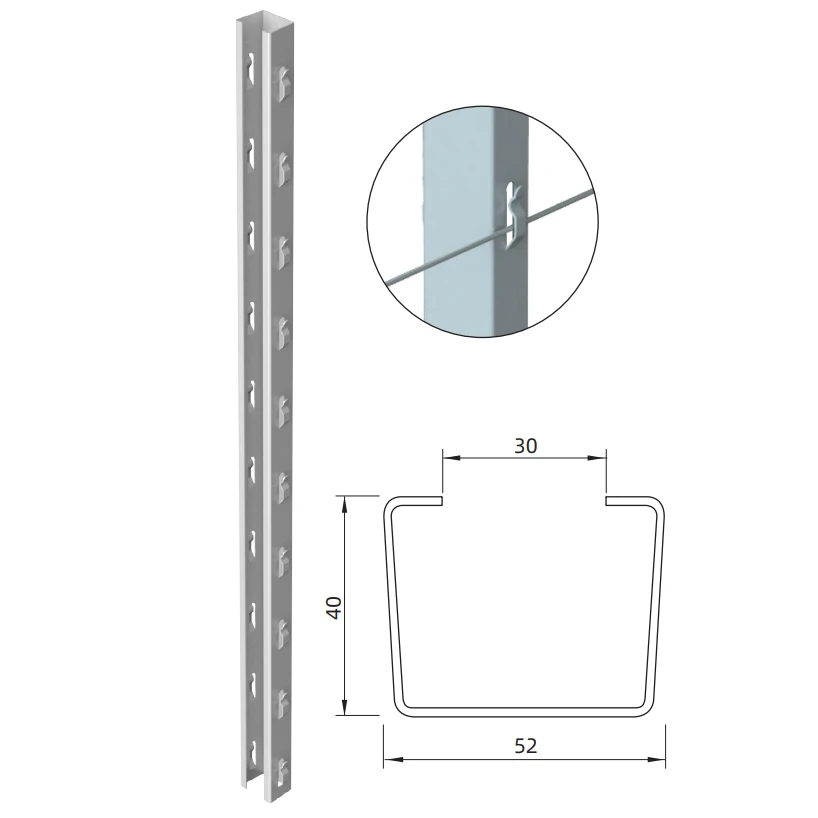

U-type wire, also known as U-shaped wire or U-bend wire, is a specific configuration of wire that is commonly used in various industrial and construction applications. Its distinct U shape offers unique advantages over traditional straight wire, making it a preferred choice in multiple sectors. This article delves into the characteristics, materials, applications, and benefits of U-type wire to provide a comprehensive understanding of its utility.

Characteristics of U-Type Wire

The U-type wire is characterized by its distinctive U shape, which provides increased stability and strength. This configuration allows for better support in tension and compression applications, making it suitable for structures that require durability and reliability. The wire is generally made from various materials, including stainless steel, galvanized steel, and other alloys, to cater to specific requirements such as corrosion resistance, tensile strength, and flexibility.

Materials Used in U-Type Wire

1. Stainless Steel Known for its corrosion resistance, stainless steel U-type wire is often used in marine and outdoor applications where exposure to moisture is a concern. Its strength and aesthetic appeal make it popular in architectural applications as well.

2. Galvanized Steel This type of wire has a protective zinc coating that offers excellent resistance to rust and corrosion. It is commonly used in fencing, construction, and utility applications, where rodent resistance is also a factor.

3. Alloys Special alloys can be used to enhance the properties of U-type wire, tailored for high-strength applications. These wires can withstand extreme temperatures and loads, making them suitable for specialized industrial uses.

Applications of U-Type Wire

u type wire

U-type wire has a myriad of applications across various industries

1. Construction U-type wire is often used in rebar connections and anchoring systems in concrete structures, providing strong support for beams and slabs during the curing process.

2. Fencing In agricultural and livestock management, U-type wire is utilized to create durable fences that effectively contain animals while being easy to install and maintain.

3. Electronics It is commonly employed in the manufacturing of electronic components, particularly in coil structures where the U shape aids in electromagnetic properties.

4. Automotive In the automotive sector, U-type wire is used in a range of applications from connecting terminals to supporting structural elements within vehicles.

Benefits of U-Type Wire

The advantages of U-type wire make it an attractive option for many industries. Its U-shape offers superior strength compared to straight wire, making it ideal for high-load applications. The flexibility of materials combined with the U shape enables easier installation and adjustments during the construction process. Furthermore, the versatility of U-type wire in various contexts means it can be customized to meet specific needs, enhancing its overall effectiveness.

Conclusion

In summary, U-type wire is a vital component in numerous industries due to its unique properties and applications. With various material options and a strong structural design, it provides effective solutions for challenges in construction, fencing, electronics, and automotive sectors. As technology advances and industries evolve, the importance of U-type wire in modern applications is likely to grow, reinforcing its status as a reliable choice for professionals around the world.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution