Wide Metal Arbor for Enhanced Stability and Versatile Applications in Various Industries

12 月 . 06, 2024 14:04

Exploring the Benefits and Applications of Wide Metal Arbors

In the realm of manufacturing and industrial applications, the importance of precision tooling cannot be overstated. One crucial component that significantly influences productivity and efficiency is the arbor. Among various types of arbors, the wide metal arbor stands out for its essential role in various machining processes. In this article, we will explore the benefits, applications, and considerations associated with wide metal arbors.

What is a Wide Metal Arbor?

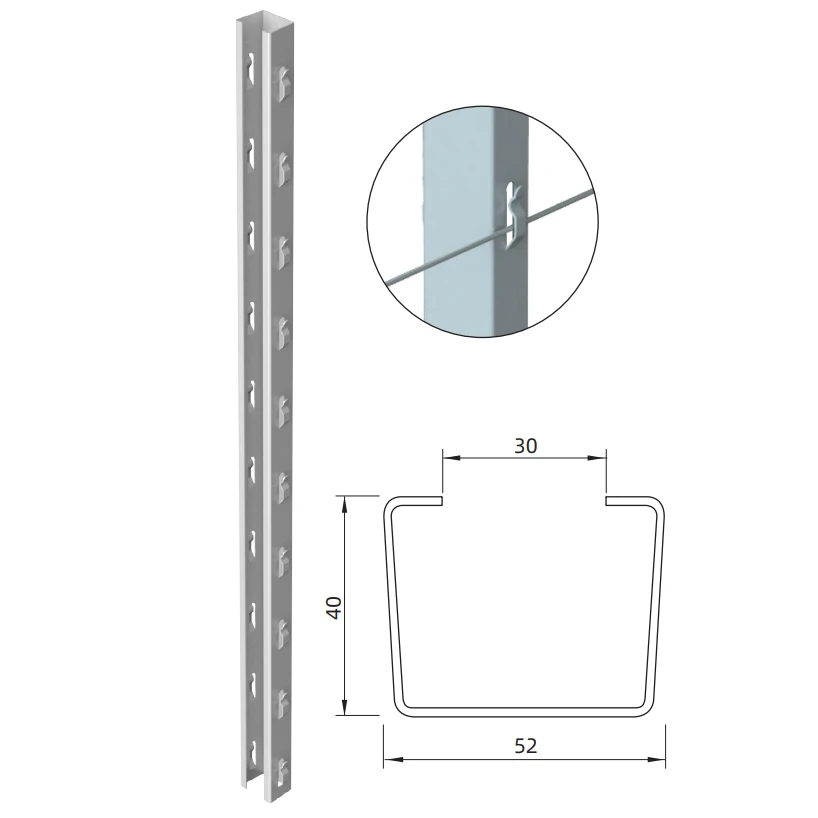

A wide metal arbor is a specialized tool used primarily in the machining of materials. It is designed to hold and attach cutting tools, such as saw blades or grinding wheels, to a rotating spindle. The term wide refers to the thickness or breadth of the arbor, which is typically wider than standard arbors. This added width enhances stability and rigidity, providing better support for heavy-duty applications.

Benefits of Wide Metal Arbors

1. Enhanced Stability The broader design of wide metal arbors contributes significantly to their stability. This is particularly crucial in high-speed operations where balance and precision are paramount. The increased surface area helps minimize vibration, leading to smoother operation and extended tool life.

2. Increased Load Capacity A wider arbor can handle higher loads without bending or deforming. This characteristic makes it especially beneficial for heavy machining tasks, where substantial forces are at play. Businesses can achieve more strenuous operations without the risk of tool failure.

3. Versatility Wide metal arbors are compatible with a variety of cutting tools, making them a versatile choice for machining centers. They can be used for milling, drilling, and even grinding applications, making them an essential component in many manufacturing setups.

4. Improved Accuracy The rigid structure of wide arbors ensures that cutting tools remain aligned during operation. This precision is critical in applications where tolerances are tight, and any deviation can lead to significant production errors.

5. Durability Constructed from robust metals, wide metal arbors offer substantial resistance to wear and tear. They can withstand harsh operating conditions, including exposure to cutting fluids, high temperatures, and abrasive materials, ensuring a long service life.

Applications of Wide Metal Arbors

wide metal arbor

Wide metal arbors find their applications in various industries, including aerospace, automotive, and construction. Some specific uses include

- Milling Operations In milling machines, wide metal arbors are used to secure and position milling cutters for shaping and finishing operations. - Sawing They are extensively used in saw machines, providing a secure platform for large saw blades, ensuring straight cuts and reducing wastage. - Grinding In grinding applications, these arbors hold abrasive wheels that are used for surface finishing, machining precision components, and sharpening tools. - Drilling Operations Wide metal arbors can also be employed in drilling applications, accommodating large drill bits for heavy-duty drilling tasks.

Considerations When Choosing Wide Metal Arbors

When selecting a wide metal arbor for your specific application, several factors should be considered

1. Compatibility Ensure that the arbor is compatible with the tools and machinery you intend to use. Proper fit is crucial for effective operation and safety.

2. Material The material of the arbor plays a significant role in its durability and performance. Choosing high-quality metals, such as stainless steel or hardened alloys, is advisable.

3. Dimensions Consider the dimensions of the arbor, including its width, length, and diameter, to ensure it fits your requirements and machining setup.

4. Maintenance Regular maintenance is essential to ensure the longevity of wide metal arbors. Proper cleaning, inspection for wear, and timely replacement are key factors in maintaining operational efficiency.

Conclusion

Wide metal arbors are an indispensable component in many industrial applications, providing stability, accuracy, and versatility. Their ability to handle heavy loads and maintain precision under high-speed conditions makes them an invaluable tool in modern manufacturing. By considering the benefits and applications of wide metal arbors, businesses can enhance their machining processes, improve product quality, and ultimately boost productivity. As industries continue to evolve, investing in high-quality wide metal arbors will remain crucial for staying competitive in the marketplace.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution