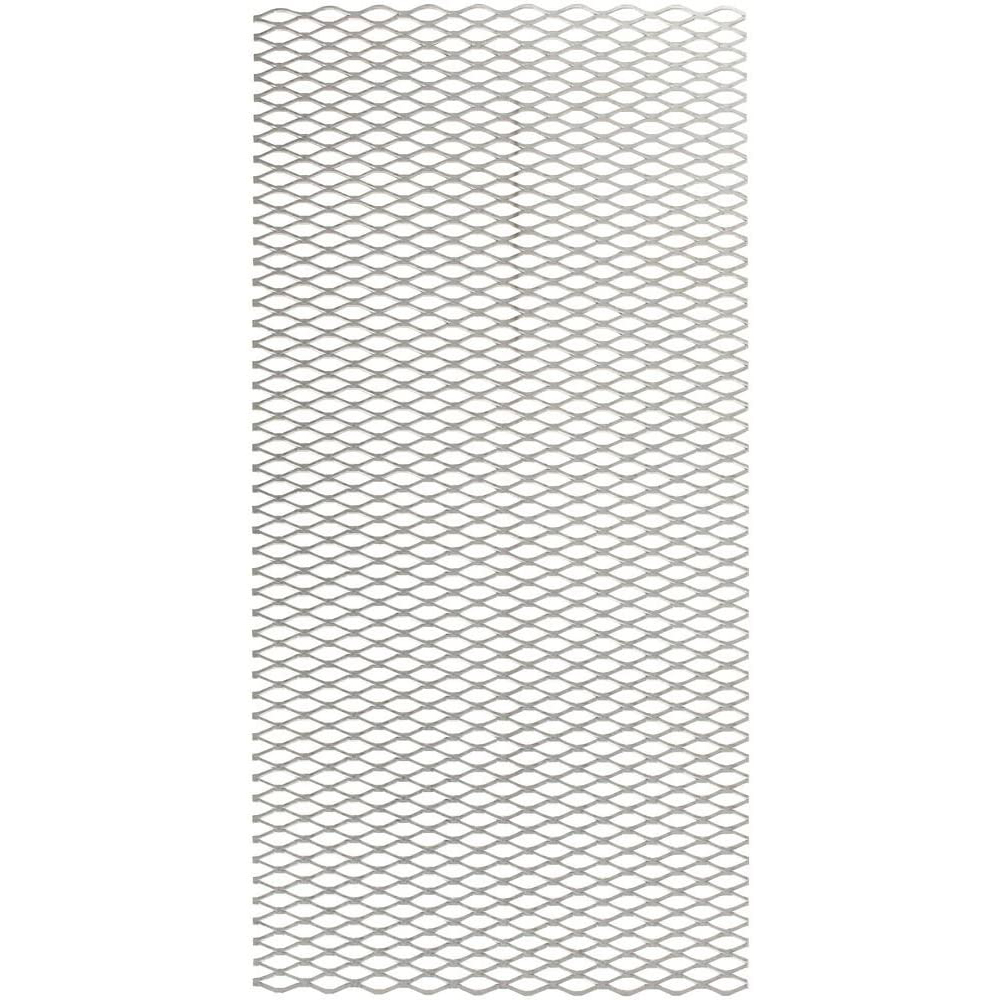

غالبًا ما تستخدم الشبكة الموسعة كعنصر زخرفي. يضيف تصميمه الفريد نسيجًا واهتمامًا بصريًا للمباني، من الداخل والخارج.

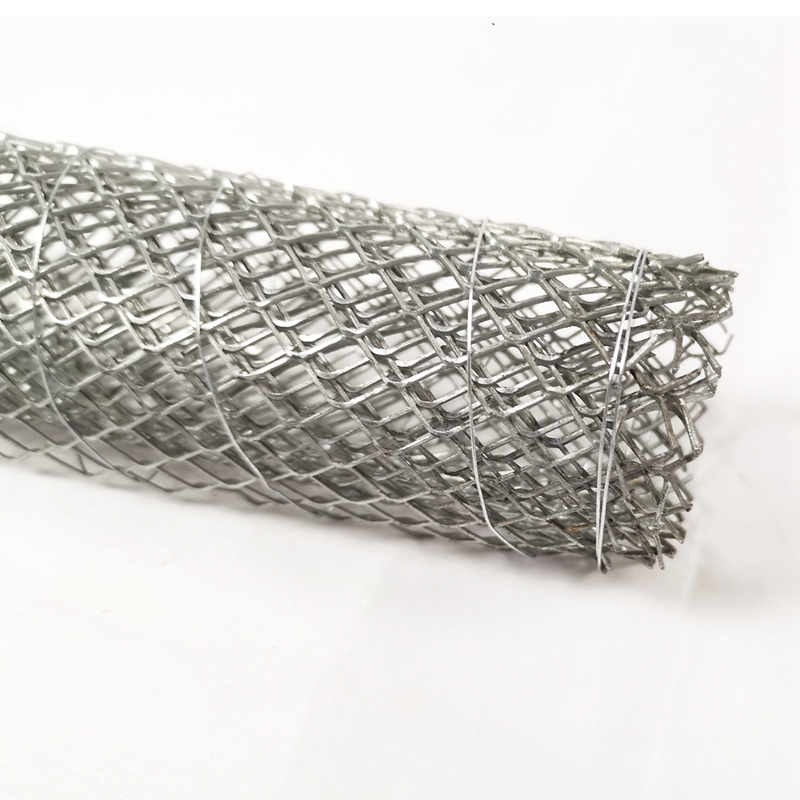

إنه نوع من الصفائح المعدنية التي يتم قطعها وتمديدها لإنشاء شبكة من الفتحات على شكل ماسة. تعمل عملية التمدد على زيادة مساحة سطح المعدن، مما يجعله أقوى وأكثر مقاومة للتآكل والتلف. القوة والصلابة تجعله خيارًا ممتازًا لتقوية

يسمح التصميم المفتوح بتدفق الهواء والتهوية، مع توفير حاجز لمنع المتطفلين غير المرغوب فيهم.

-

الشبكة الموسعة هي مادة متعددة الاستخدامات ولها نطاق واسع من التطبيقات في صناعات مثل البناء والهندسة المعمارية والتصنيع.

-

في صناعة البناء، تُستخدم الشبكة الموسعة عادةً في الأسوار وواجهات المباني والشاشات الأمنية. ويمكن استخدامها في الكسوة أو واقيات الشمس أو كجدار مميز. كما يسمح التصميم المفتوح للضوء بالمرور، مما يخلق لعبة من الضوء والظل تضيف عمقًا وأبعادًا إلى المساحة.

-

تستفيد الصناعات التحويلية أيضًا من استخدام الشبكات الموسعة. يُستخدم بشكل شائع كحاجز أمان في الآلات والمعدات، مما يوفر الحماية للعمال مع السماح بالرؤية والوصول إلى مكونات التشغيل.

-

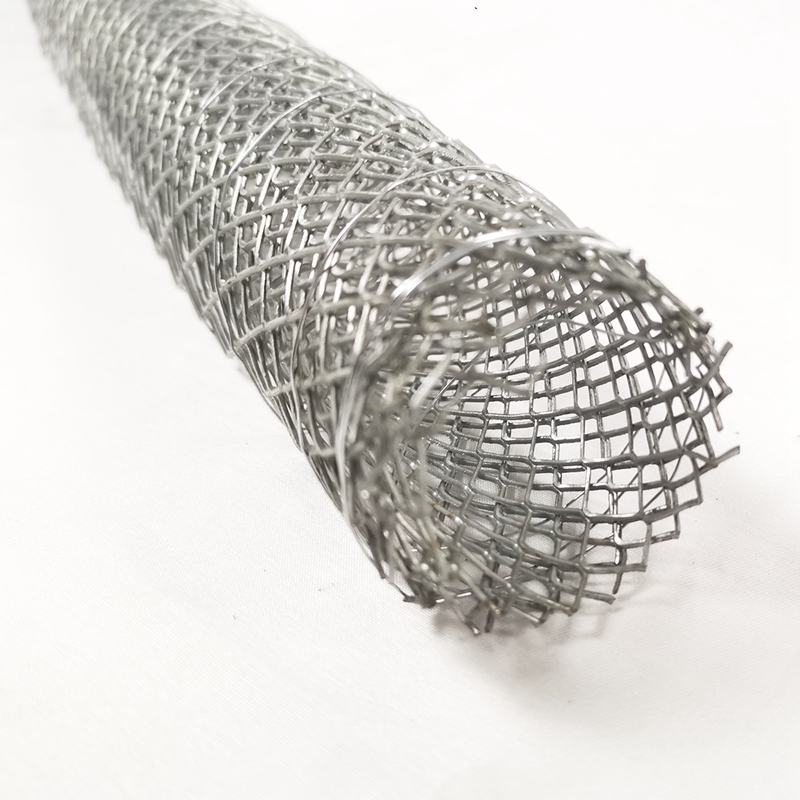

بالإضافة إلى ذلك، يمكن استخدامه كمرشح في تطبيقات مختلفة، مثل أنظمة تكييف الهواء أو العمليات الصناعية، حيث يحبس الجزيئات بشكل فعال بينما يسمح بالتدفق الحر للهواء أو السائل.

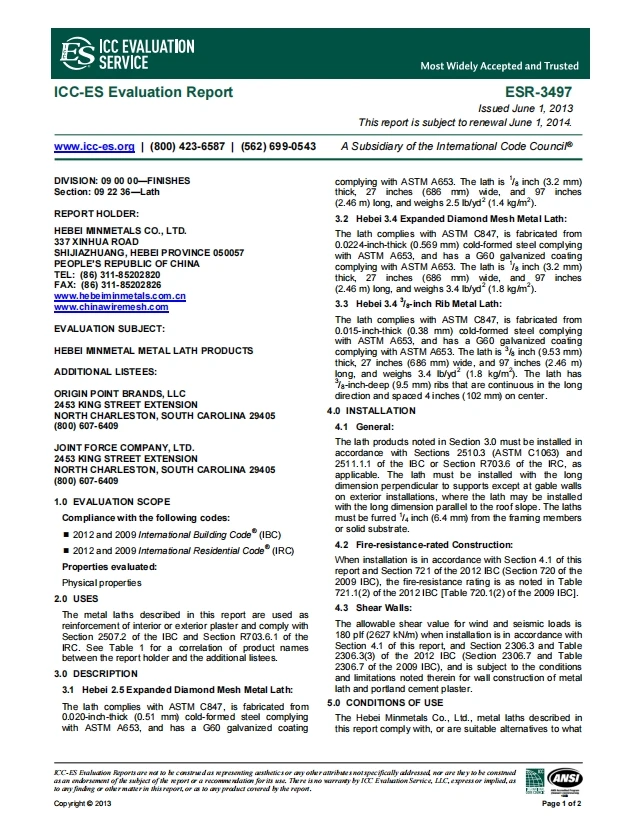

Expanded Mesh Specification

| WIR/175MLIMP 1.75 رطل لوح معدني مسطح |

| WIR/25MLIMP 2.50 رطل لوح معدني مسطح |

| WIR/34MLIMP 3.40 رطل لوح معدني مسطح |

| HEB/GDML25 2.50 رطل لوح معدني مدمل |

| WIR/RBLTHNPIMP لوح معدني مضلع بوزن 3.40 رطل بدون ورق |

| WIR/RBLTHIMP 3.40 رطل من اللوح المعدني المضلع مع الورق |

-

تتوفر الشبكة الموسعة في مجموعة متنوعة من المواد، بما في ذلك الفولاذ المقاوم للصدأ والألومنيوم والفولاذ الصلب. تتمتع كل مادة بخصائصها الفريدة التي تجعلها مناسبة لتطبيقات مختلفة.

-

يوفر الفولاذ المقاوم للصدأ مقاومة ممتازة للتآكل، مما يجعله مثاليًا للاستخدام في البيئات الخارجية أو المناطق المعرضة للمواد الكيميائية أو الرطوبة. الألومنيوم خفيف الوزن وله نسبة عالية من القوة إلى الوزن، مما يجعله مناسبًا للتطبيقات التي يشكل فيها الوزن مصدر قلق.

-

الشبكة الموسعة هي مادة متعددة الاستخدامات توفر مجموعة واسعة من التطبيقات في مختلف الصناعات. سواء تم استخدامها في البناء أو الهندسة المعمارية أو التصنيع، توفر الشبكة الموسعة حلاً فعالاً من حيث التكلفة والكفاءة للعديد من الاحتياجات المختلفة.

What Is Expanded Metal Mesh

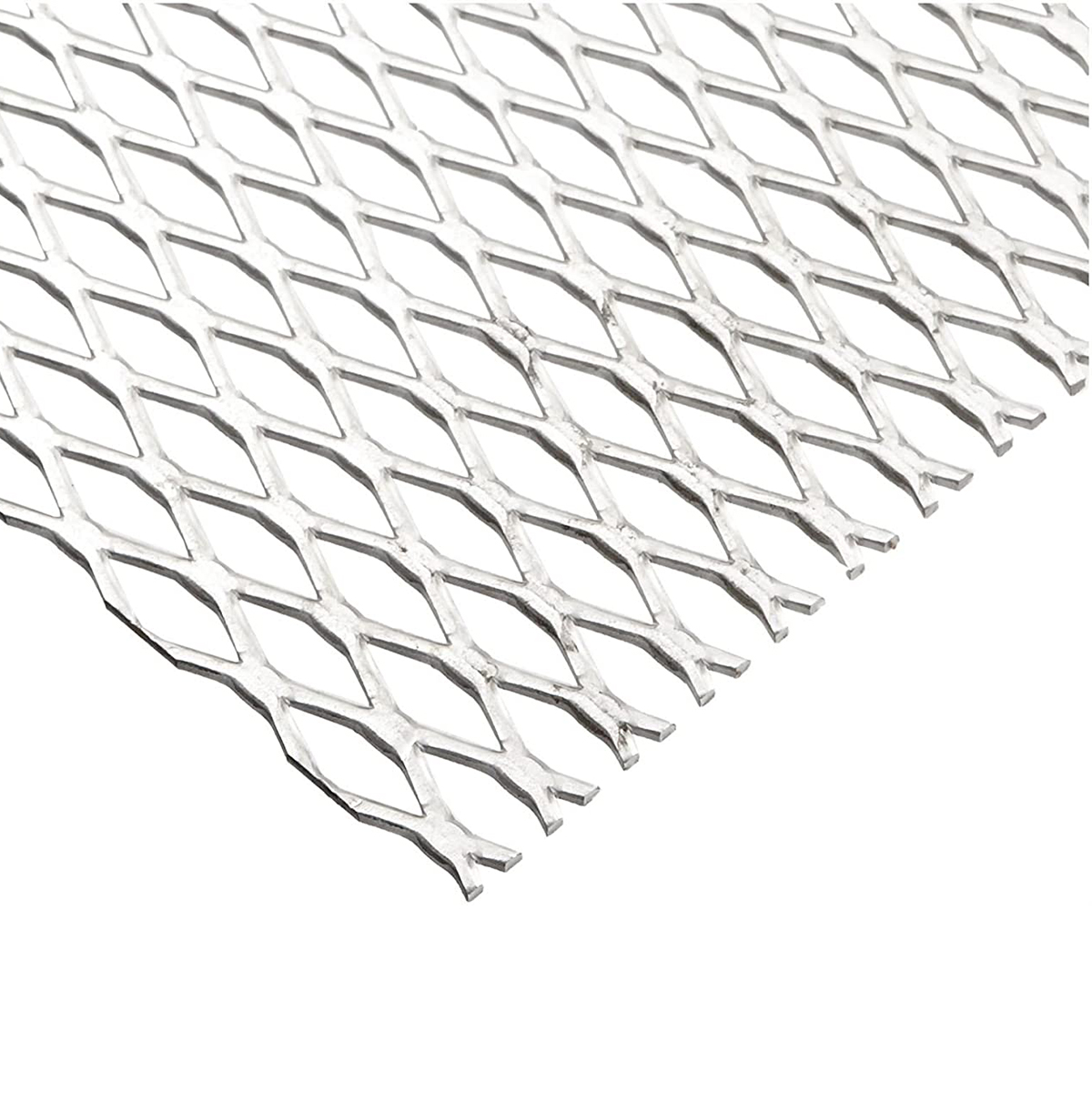

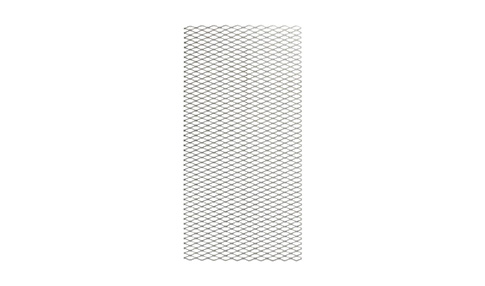

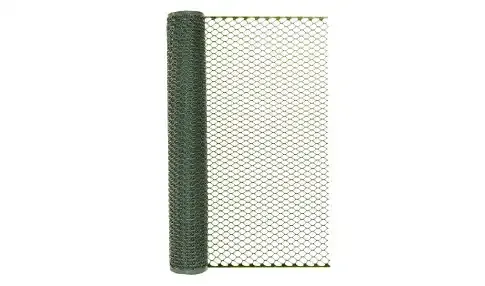

Expanded metal mesh is a versatile and durable material commonly used in various industries, including construction, security, and manufacturing. It is created by cutting a sheet of metal and stretching it to form a mesh with diamond-shaped openings. Unlike welded wire mesh, expanded metal does not require additional joints or welding; the material is simply slit and expanded, making it stronger than traditional sheets of metal. This process results in a lightweight yet robust mesh that can bear heavy loads.

The mesh's structure is ideal for applications where strength, flexibility, and security are essential. Its unique shape allows for excellent airflow, making it an ideal choice for ventilation systems, grilles, and protective barriers. Expanded metal mesh is often used in building facades, stair treads, and platforms due to its ability to withstand harsh environmental conditions while maintaining its form.

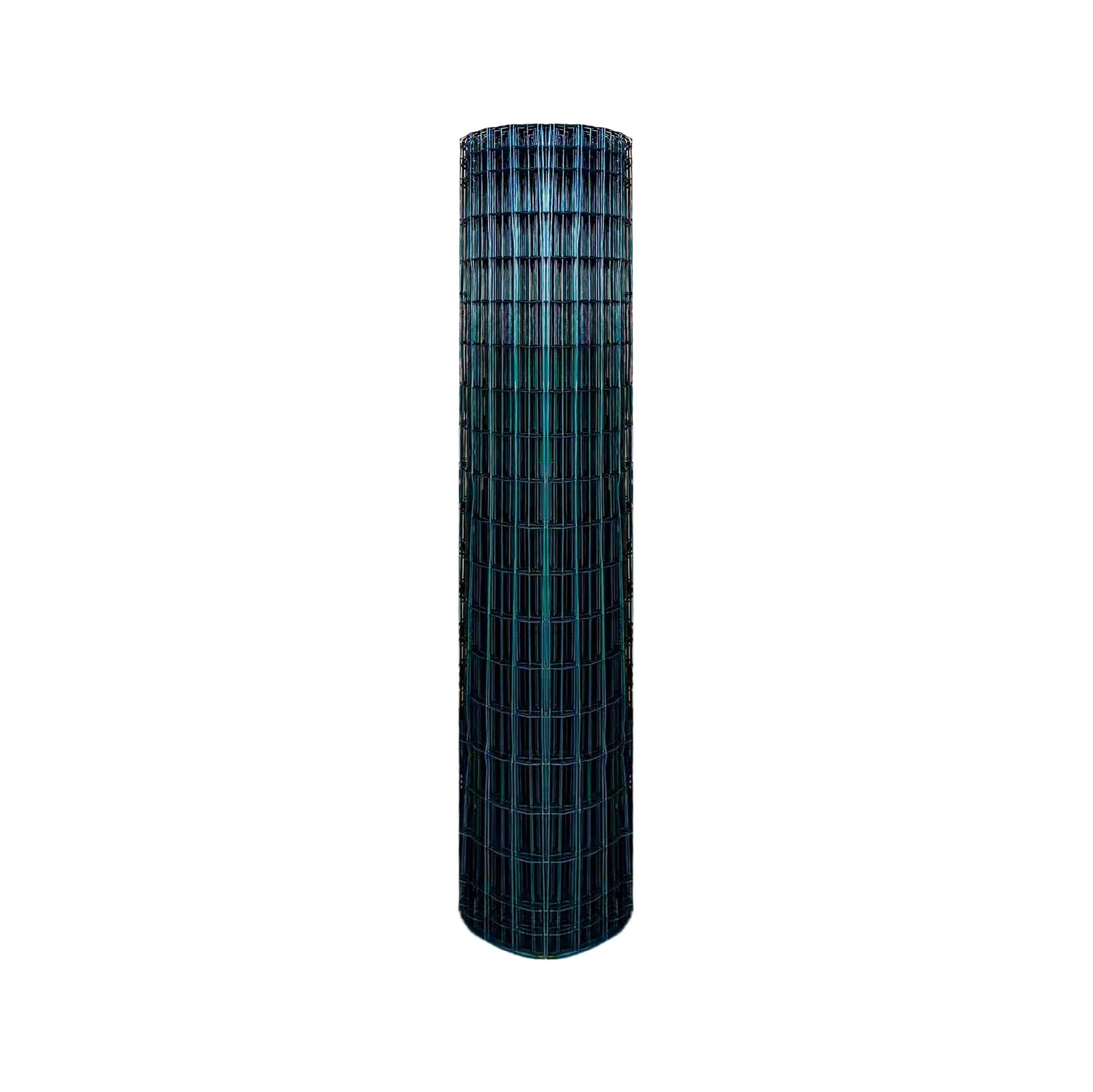

This mesh is available in a variety of materials, including steel, aluminum, stainless steel, and brass, allowing it to be customized for specific purposes. It also comes in different thicknesses, with some types being more suitable for security and heavy-duty applications, while others are perfect for decorative and lighter uses.

Thanks to its ability to be shaped into various sizes and patterns, expanded metal mesh is also a popular choice for architectural designs, fences, and screens. Its durability, low maintenance, and adaptability make it an excellent material for both functional and aesthetic purposes in a wide range of sectors.

فوائد الشبكة المعدنية الموسعة

Strength and Durability

Expanded mesh is inherently stronger than other types of metal sheets because it is formed by cutting and stretching a single sheet of metal, creating a continuous, reinforced structure. This eliminates the need for welding or additional fasteners, making it more robust and durable. It can withstand heavy loads and harsh environmental conditions, making it ideal for use in industrial applications.

Lightweight Yet Strong

Despite its robust properties, expanded wire mesh remains lightweight due to its open structure. This makes it easy to handle, transport, and install, which can be a significant cost-saving factor in many projects.

Cost-Effective

Expanded metal mesh is often more affordable than traditional welded mesh. The manufacturing process is efficient, with minimal waste, which translates into lower production costs. Furthermore, since expanded wire mesh is highly durable, it reduces the need for frequent replacements, making it a long-term, cost-effective solution.

Versatility and Customization

Available in various materials such as aluminum, stainless steel, and carbon steel, expanded mesh can be tailored to meet specific needs. Whether you're looking for lightweight panels for architectural designs or heavy-duty mesh for industrial use, the expanded metal mesh can be customized for different purposes.

Enhanced Security and Protection

Expanded metal mesh provides excellent protection against unauthorized access, making it a top choice for fencing, gates, and protective barriers. Its design ensures that it is difficult to cut or break, enhancing security in various environments.

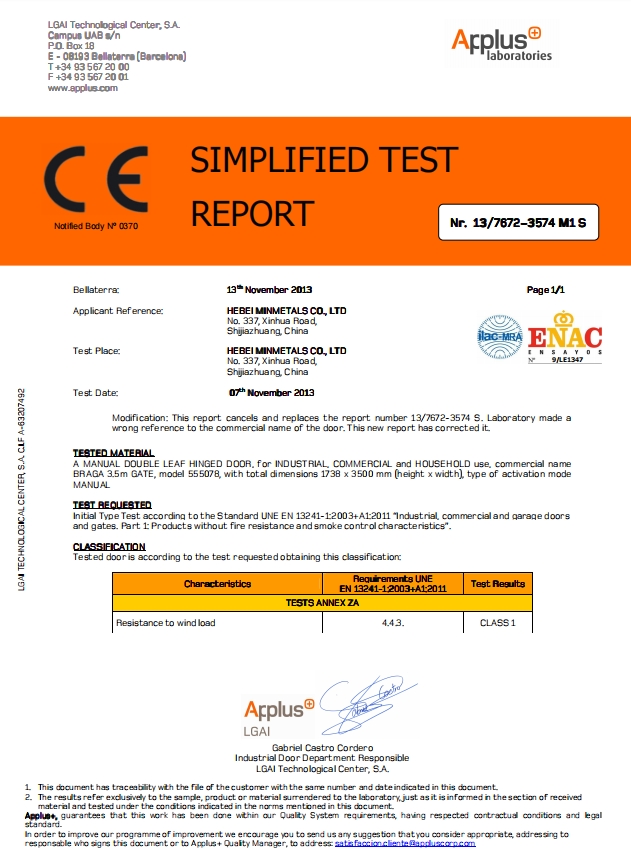

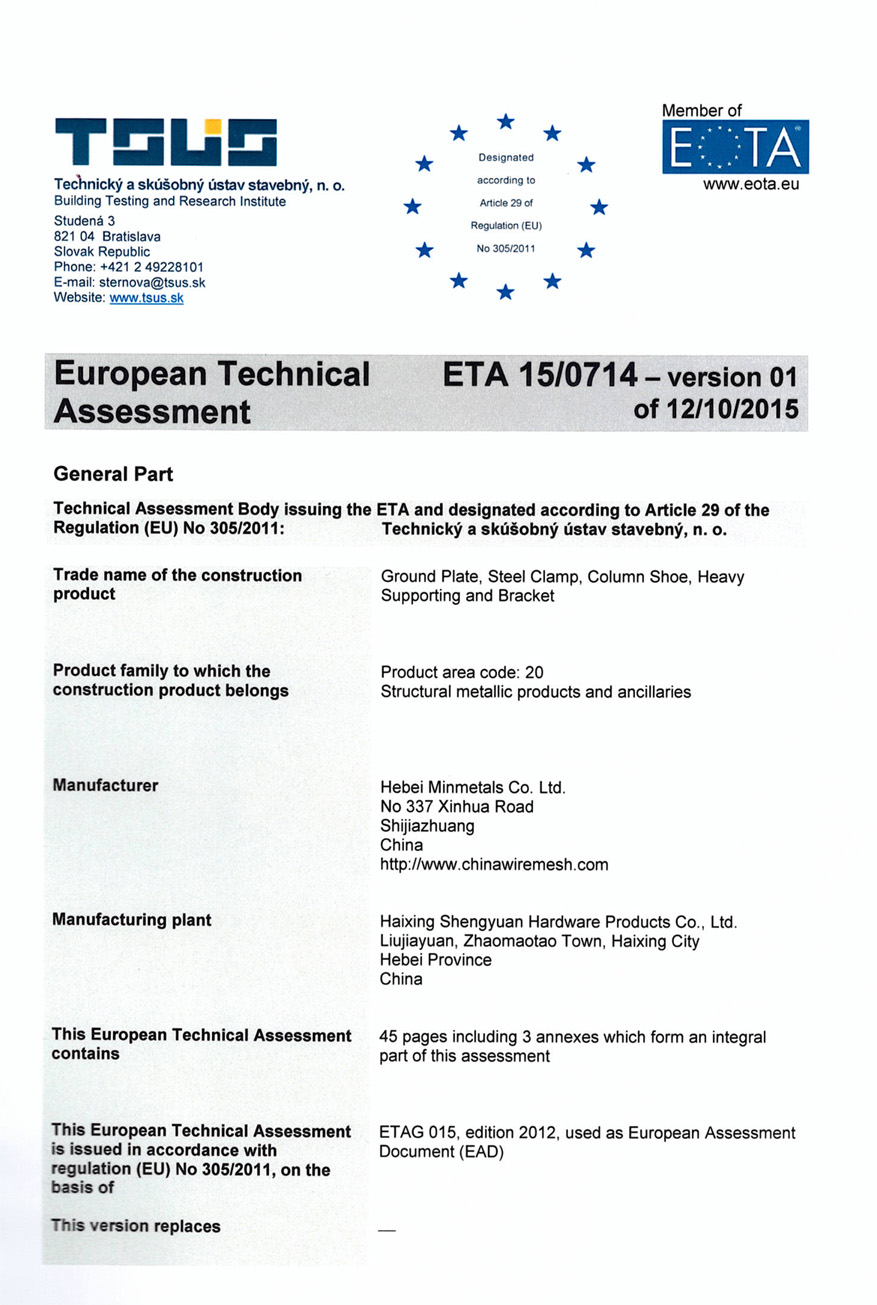

Availability and Supplier Options

خبى مينميتالز, a leading expanded wire mesh supplier, offers a wide range of high-quality wire mesh wholesale. Whether you're looking for expanded metal mesh for sale or seeking a competitive expanded wire mesh price, Hebei Minmetals provides solutions to fit various budgets and requirements.

What Is the Difference Between Welded Mesh and Expanded Mesh?

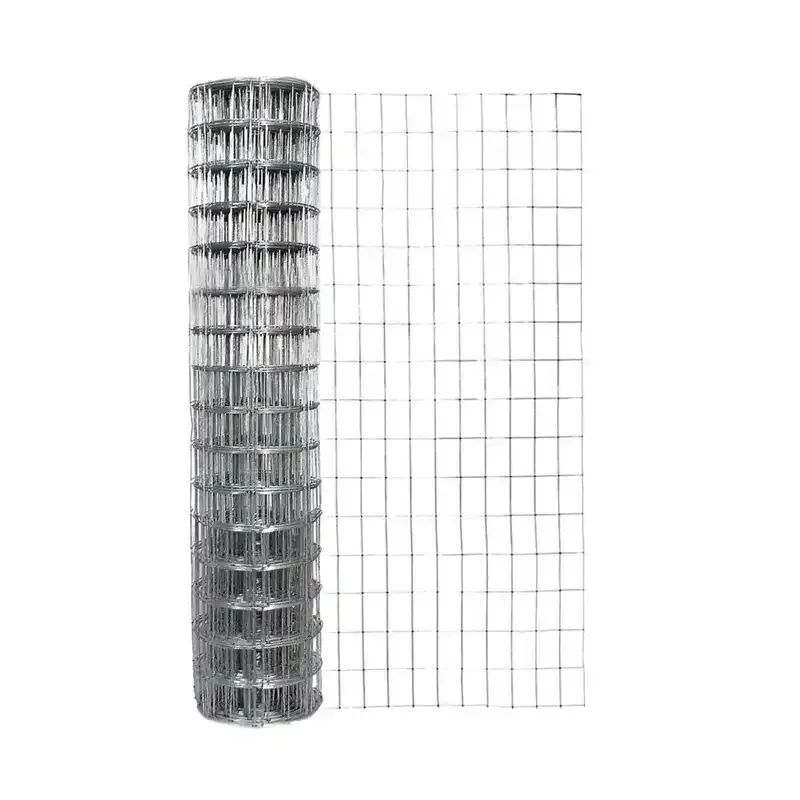

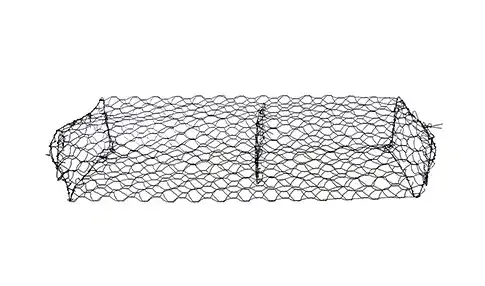

Welded mesh, also known as welded wire mesh, is created by welding intersecting wires together at right angles. This process results in a strong, rigid structure with uniform spacing between the wires. The mesh is available in different gauges and sizes, making it suitable for a wide variety of applications, such as fencing, reinforcement in concrete, and protective barriers. Welded mesh is appreciated for its strength and durability, making it an excellent choice for applications requiring high structural integrity. It is typically made from carbon steel but can also be coated with materials like galvanized zinc to enhance corrosion resistance.

In contrast, expanded mesh is produced by cutting and stretching a flat sheet of metal, such as aluminum or stainless steel, into a mesh form. This process creates a series of diamond or hexagonal openings, which allows for greater airflow, light transmission, and drainage compared to welded mesh. Expanded mesh is lightweight yet strong, making it ideal for applications like architectural facades, walkway covers, and decorative elements. The open structure of expanded mesh also allows for visibility and aesthetic appeal, which is often desired in design-focused projects.

In summary, the primary difference between welded mesh and expanded mesh lies in their manufacturing processes, structural characteristics, and application suitability. Welded mesh offers strength and rigidity for load-carrying applications, while expanded mesh provides lightweight and versatile options with enhanced airflow and aesthetics. Choosing between the two depends on the specific requirements of the project, including strength, visibility, and environmental factors.

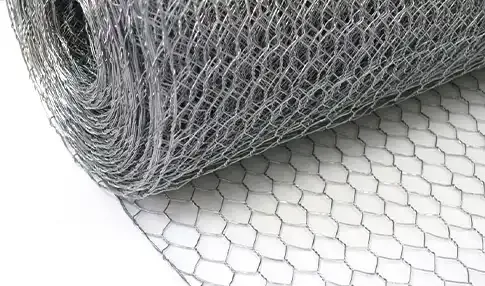

The standard size of expanded metal can vary depending on the specific application and manufacturing processes, but there are common dimensions and types that are frequently used in the industry.

Typically, expanded metal sheets come in standard sizes such as 4 x 8 metal mesh or 3 feet by 6 feet. These dimensions are convenient for handling, transportation, and installation. However, custom sizes can also be produced to meet specific project requirements. The thickness of the base metal can vary, generally ranging from 0.035 inches to 0.125 inches, depending on the desired strength and application.

Expanded metal sheets are categorized into different types based on the mesh pattern. The most common types include standard expanded metal, flattened expanded metal, and architectural expanded metal, each having its unique characteristics that affect dimensions. The opening size of the mesh can also differ, with standard opening sizes being around 1/2 inch to 1 inch, allowing for variations in airflow and light passage.

In terms of material, expanded metal is commonly made from steel, aluminum, and other metals, each of which may have different standard dimensions and thicknesses. Steel expanded metal is particularly popular for its strength, while aluminum is preferred for its lightweight and corrosion resistance.

In conclusion, while standard sizes for expanded metal typically include 4 x 8 expanded metal sheets with varying thicknesses and opening sizes, the flexibility in manufacturing allows for a wide range of dimensions to cater to specific needs in various industries.