galvanized iron binding wire

11月 . 13, 2024 04:07

The Versatility of Galvanized Iron Binding Wire

Galvanized iron binding wire is a critical component in various sectors, including construction, agriculture, and manufacturing. Its unique properties, including corrosion resistance and high tensile strength, make it an ideal choice for a wide range of applications.

Galvanization is the process of coating iron or steel with a layer of zinc to prevent rusting. This protective barrier significantly extends the lifespan of the wire, making it suitable for outdoor use. Unlike plain iron wire, galvanized iron binding wire can withstand various weather conditions, which is essential for any application exposed to moisture, such as farm fences, gates, and scaffolding. The ability to resist corrosion means that galvanized binding wire is less likely to deteriorate over time, ensuring reliability in structural applications.

One of the main uses of galvanized iron binding wire is in construction, where it is employed for tying reinforcement bars (rebar) in concrete structures

. The strength of the wire provides the necessary support to keep the rebar in place, ultimately enhancing the stability and durability of buildings. Construction workers appreciate the ease of handling and manipulation of binding wire, allowing for quicker installations and reducing labor costs. Additionally, the wire is available in various gauges, enabling users to choose a specific thickness that will meet the requirements of different projects.galvanized iron binding wire

In agriculture, galvanized iron binding wire plays an essential role in maintaining livestock and securing crops. Farmers often use it to create fences, which not only keep animals in but also protect crops from wildlife. The flexibility of binding wire allows for easy weaving and securing, making it feasible to erect barriers that can follow the contours of the land. Furthermore, it is commonly used for bundling hay or other agricultural products, facilitating transportation and storage.

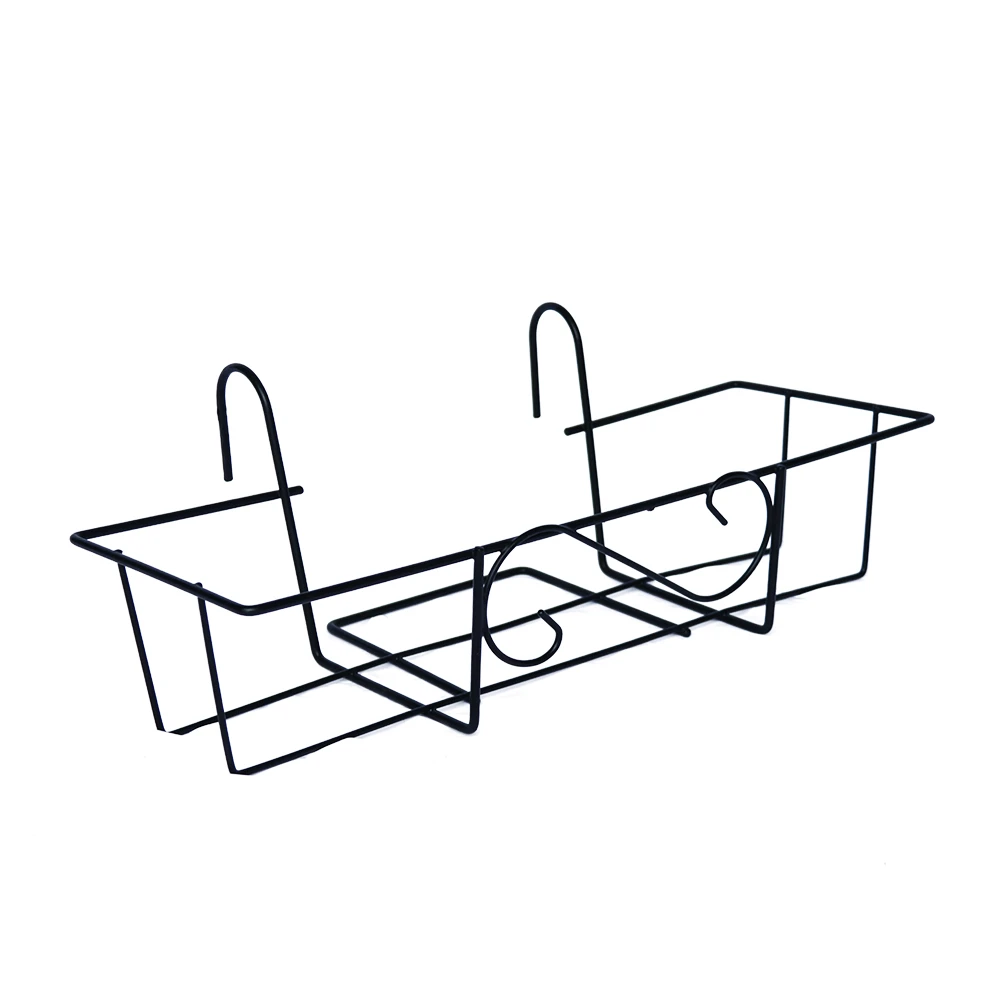

Galvanized iron binding wire is also prevalent in the manufacturing sector. It serves various purposes, from forming frames for packaging to being used in craft and DIY projects. The wire's malleability enables creators to bend and shape it into various forms, leading to innovations in product design. Whether it's for binding items together or creating intricate designs, the versatility of the binding wire is widely recognized by artisans and manufacturers alike.

Environmental concerns regarding metal waste have prompted many industries to consider the efficiency of their materials. Galvanized iron binding wire is often recyclable, contributing to a sustainable approach in manufacturing. By reusing materials, businesses can reduce their carbon footprint and promote a circular economy.

In conclusion, galvanized iron binding wire is a fundamental material with immense versatility across multiple industries. Its resistance to corrosion, high tensile strength, and ease of use make it an indispensable choice in construction, agriculture, and manufacturing. As industries continue to look for sustainable solutions, the long-lasting nature and recyclability of galvanized iron binding wire will keep it in demand for years to come. Whether for practical applications or creative projects, this unassuming wire contributes significantly to the modern landscape.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution