sheet metal mesh screen

12月 . 20, 2024 06:07

Understanding Sheet Metal Mesh Screens

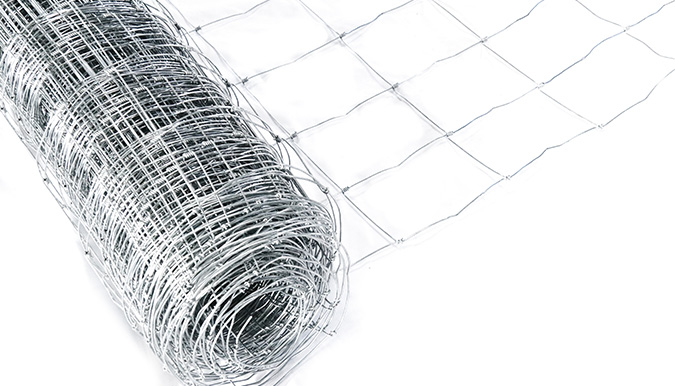

Sheet metal mesh screens have become an essential component in various industries due to their versatility, durability, and efficiency. Made from thin sheets of metal that have been perforated or woven, these screens are commonly used for filtration, separation, and protection in architectural, industrial, and automotive applications.

Properties and Benefits

One of the primary advantages of sheet metal mesh screens is their strength. The use of metals such as stainless steel, aluminum, or galvanized steel ensures that the screens are resistant to rust and corrosion, thereby prolonging their lifespan. Stainless steel, in particular, is favored in many applications due to its superior resistance to extreme environments, making it ideal for use in chemical processing, food production, and outdoor applications.

Another significant benefit is the customizable nature of these screens. Manufacturers can produce mesh screens in various sizes, thicknesses, and openings, catering to specific needs of different industries. A tightly woven mesh might be ideal for filtration applications, while a more open design can facilitate airflow or protect machinery from larger debris.

Applications of Sheet Metal Mesh Screens

The applications of sheet metal mesh screens are vast. In the construction industry, they are often utilized as protective barriers or façade elements. The aesthetic qualities of these screens can enhance building designs, while their functional forms serve to filter light, reduce heat, and improve energy efficiency.

sheet metal mesh screen

In the manufacturing realm, mesh screens are critical in the process of filtration. They help in separating solids from liquids or gases, ensuring that machinery operates efficiently and that end products meet quality standards. For instance, in water treatment facilities, finely perforated screens are essential in filtering contaminants from water, making it safe for consumption.

Another noteworthy application is in the automotive sector. Mesh screens can be found in gas and oil filters, preventing debris from entering the engine and thereby extending its life. Additionally, they are used in various components such as grilles and heat exchangers, contributing significantly to vehicle performance and safety.

Challenges and Considerations

While sheet metal mesh screens offer numerous advantages, there are challenges associated with their use. The choice of material and the design of the mesh are crucial, as an inappropriate selection can lead to premature failure or inefficiency in the intended application. Additionally, maintaining the integrity of these screens is essential; regular inspections and replacements are necessary to avoid failures, especially in critical systems like food processing or chemical manufacturing.

Another consideration is the cost. Although sheet metal mesh screens can be cost-effective solutions, the initial investment must be weighed against long-term savings achieved through durability and reduced maintenance needs. Companies should consider the total cost of ownership rather than just the upfront price.

Conclusion

In summary, sheet metal mesh screens are indispensable tools across various industries, achieving a perfect balance between functionality and aesthetics. Their strength and versatility make them suitable for a broad range of applications, from filtration to protection. As industries continue to evolve and demand more efficient solutions, the importance of sheet metal mesh screens is likely to grow, further solidifying their role in modern manufacturing and construction processes.