square axle spindle

11月 . 08, 2024 15:23

Understanding the Square Axle Spindle Key Concepts and Applications

The square axle spindle is a critical component in various mechanical and engineering applications, primarily within the realms of automotive and machinery design. Understanding what a square axle spindle is, its design benefits, applications, and maintenance can provide valuable insights for engineers and enthusiasts in these fields.

What is a Square Axle Spindle?

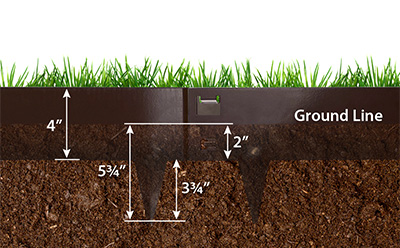

A square axle spindle is a type of spindle that features a square cross-section. Unlike traditional round spindles, square axles offer increased surface area and unique stress distribution characteristics. This design allows for enhanced torque transmission and load-carrying capabilities, making them suitable for specific applications where strength and stability are paramount.

Design Benefits

The advantages of square axle spindles begin with their geometry. The square shape provides multiple faces for contact, which can improve the overall grip in assemblies and reduce slippage during operation. This is particularly advantageous in applications where high torque is required, as the square profile can effectively transfer forces without compromise.

Another significant benefit of square axles is their ease of alignment. When components are designed to fit onto a square spindle, it becomes straightforward to ensure that they are properly oriented. This can reduce installation time and complexity, which is crucial in both manufacturing and maintenance environments.

Additionally, square spindles can be more durable than their round counterparts. The increased surface area can help distribute heat more effectively, leading to less wear and tear over time. This durability makes them a favored choice for heavy-duty applications where consistent performance is necessary.

Applications

square axle spindle

Square axle spindles find their primary application in various fields, including agriculture, construction, and automotive industries. In agricultural machinery, they are often used in tillers and harvesters where significant stress is placed on the driveline. The reliable transfer of torque and load offered by square spindles is essential for the efficient operation of these machines.

In the construction industry, square axle spindles are commonly found in equipment such as cranes and heavy transport vehicles

. The stability and strength provided by this design allow for safer operations under hefty loads and in challenging environments.Furthermore, in the automotive sector, square axle spindles can be utilized in custom vehicle builds or modifications. Enthusiasts looking to enhance the performance of their vehicles may opt for square axle configurations for better traction and handling.

Maintenance and Care

Maintaining square axle spindles is vital to ensure their longevity and performance. Regular inspection for wear and technology is essential, especially in high-performance applications. Look for signs of distress such as chipping, deformation, or surface rust, which could indicate a need for immediate replacement or repair.

Lubrication is another critical aspect of maintenance. Using the correct type of lubricant helps reduce friction and prevents wear between the spindle and any associated components. It is crucial to adhere to manufacturer recommendations when it comes to both lubrication intervals and types of lubricants used.

Conclusion

In summary, square axle spindles are more than just a mechanical component; they represent a design that embraces efficiency, durability, and ease of use in high-demand environments. Their unique square design offers distinct advantages in load handling, alignment, and overall performance, making them an indispensable choice in various applications, particularly within agriculture, construction, and automotive sectors.

Understanding the intricacies of square axle spindles—from their design benefits and applications to proper maintenance—can help engineers and users leverage their full potential, ensuring reliable operation over time. As industries evolve, the continued innovation within spindle design will likely yield even more advancements, keeping square axle spindles relevant for years to come.