stacking pallet racks

10月 . 11, 2024 08:45

Understanding the Importance of Stacking Pallet Racks in Warehousing

In the modern logistics and warehousing industry, efficiency and space utilization are paramount. One of the key solutions to optimizing storage space is the use of stacking pallet racks. These systems are designed to hold pallets of various sizes, providing a structured environment for organizing inventory. This article will delve into the advantages of stacking pallet racks, their types, best practices for implementation, and their impact on overall warehouse operations.

What Are Stacking Pallet Racks?

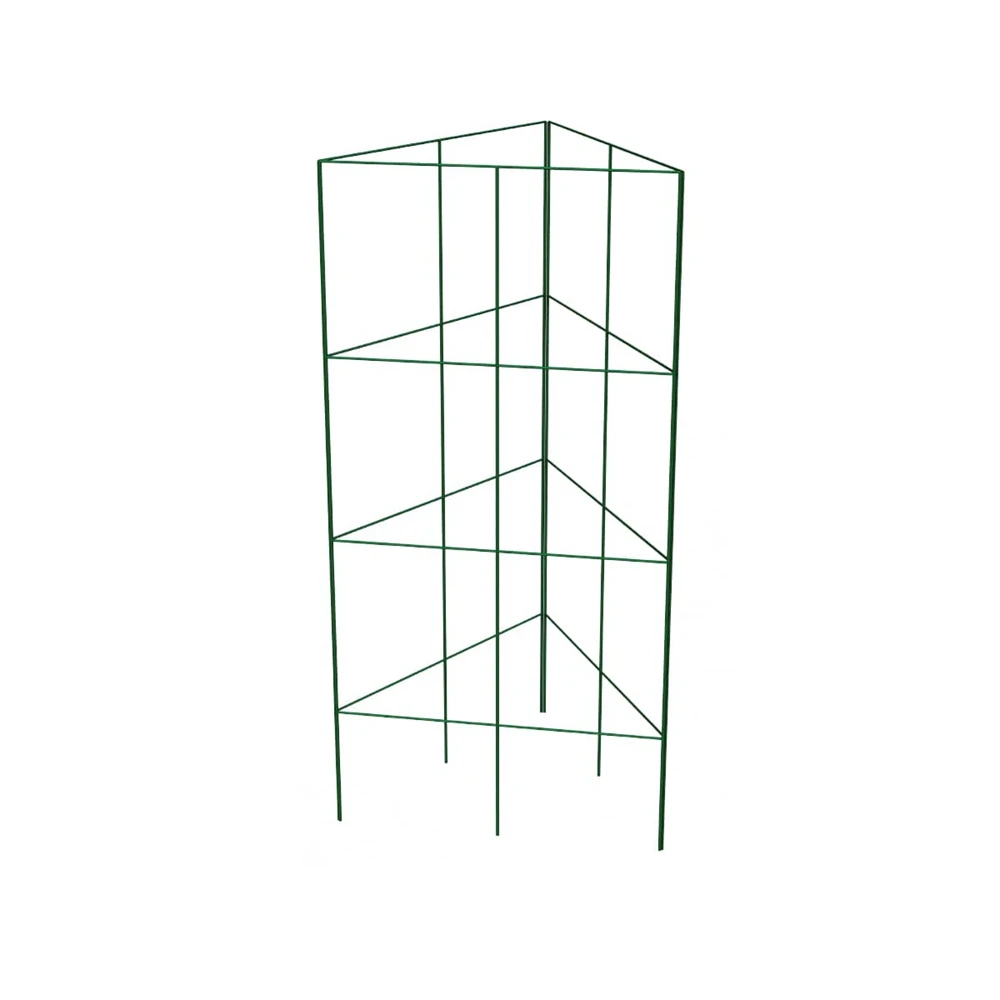

Stacking pallet racks are frameworks that facilitate the vertical storage of goods on pallets. They are typically made from robust steel and allow for easy access to stored items using forklifts or material handling equipment. The design of these racks encourages maximizing warehouse space—storing items vertically rather than horizontally—thereby improving storage capabilities without significantly increasing the warehouse footprint.

Advantages of Stacking Pallet Racks

1. Space Optimization One of the most significant benefits of stacking pallet racks is their ability to maximize vertical space. Warehouses can stack goods in a way that significantly increases storage capacity, allowing businesses to make the most of their available square footage.

2. Improved Inventory Management With organized stacking, warehouses can implement more effective inventory management practices. Items can be easily located, and stocktaking becomes a more straightforward process, facilitating better decision-making regarding inventory levels and reordering.

3. Enhanced Accessibility Stacking pallet racks allow for easy accessibility to products. Forklifts can maneuver between aisles, quickly retrieving goods as needed. This efficiency is crucial in fast-paced environments where time is of the essence.

4. Safety and Stability Modern stacking pallet racks are designed with safety features that prevent the collapse of stacked goods. This ensures a secure environment for employees and reduces the risk of accidents and injuries. Furthermore, these racks can be customized to withstand various weight loads, ensuring stability across different types of inventory.

5. Versatility Stacking pallet racks come in various configurations, allowing them to accommodate a wide range of products. Whether storing heavy engineering equipment or lightweight consumer goods, there is a suitable pallet rack solution available.

Types of Stacking Pallet Racks

There are several types of stacking pallet racks, each tailored for specific storage needs

stacking pallet racks

- Selective Racks These are the most common type and allow for easy access to each individual pallet without needing to move other pallets first.

- Drive-In/Drive-Through Racks These systems are designed for high-density storage, allowing forklifts to drive directly into the rack structure, enabling the storage of large quantities of similar items.

- Push Back Racks These racks allow pallets to be loaded from one side and retrieved from the other, optimizing space while allowing for FIFO (First In, First Out) inventory management.

- Flow Racks Ideal for perishable goods, these racks use gravity to move pallets towards the pick face, ensuring that older stock is picked before newer stock.

Best Practices for Implementation

To maximize the benefits of stacking pallet racks, businesses should adhere to best practices such as

1. Proper Planning Before installation, assess your warehouse layout to determine the best configuration for your stacking racks based on your inventory size and types.

2. Regular Maintenance Ensure that racks are regularly inspected for wear and tear. This maintenance helps avoid accidents and ensures the longevity of the racking system.

3. Training Employees Invest in training for staff on the proper use of stacking pallet racks and safety protocols when operating forklifts within the racking environment.

4. Utilizing Technology Incorporate inventory management software to track stock levels and turnover rates, aiding in the effective management of warehouse operations.

Conclusion

Stacking pallet racks serve as a backbone for efficient warehouse management, facilitating better use of space and resources while ensuring safety. As the demands of logistics evolve, investing in stacking pallet racks can lead to improved productivity and ultimately contribute to a business's bottom line. As companies continue to seek ways to enhance operational efficiency, these systems will remain vital in the warehousing landscape.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution