Straight Cut Wire - Precise Lengths, Clean Ends, Bulk Supply

11月 . 10, 2025 16:10

Straight Cut Wire is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of iron wire, steel wire and its products. This article explores how Hebei Minmetals Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Straight Cut Wire Overview

- Benefits & Use Cases of Straight Cut Wire in Manufacturing of iron wire, steel wire and its products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Straight Cut Wire from Hebei Minmetals Co., Ltd.

Straight Cut Wire Overview

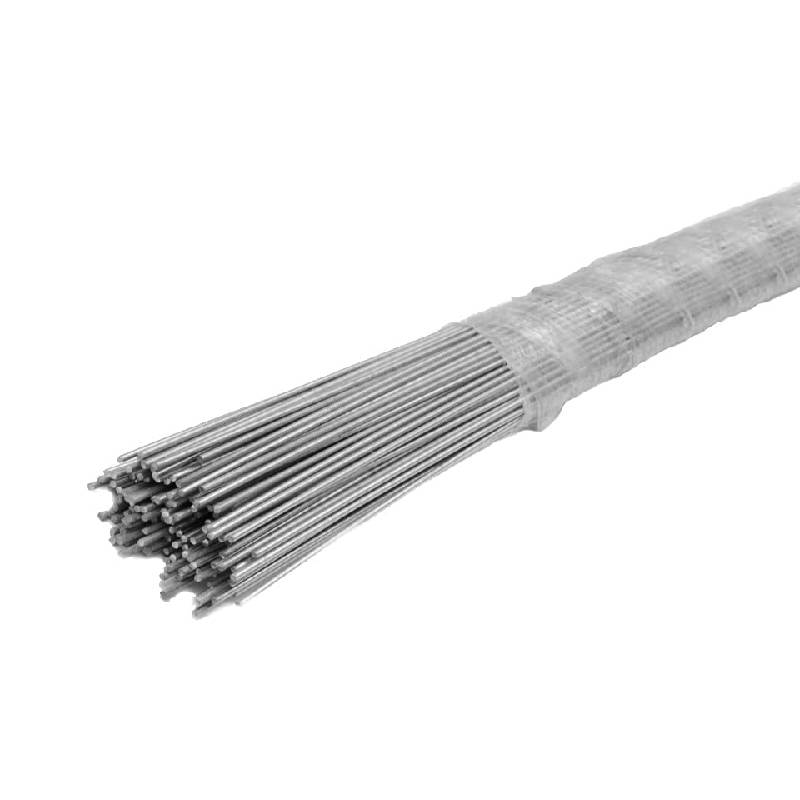

Straight cut wire—also called straightened wire, straight and cut wire, or cut straight wire—is low- to medium-carbon steel wire supplied in precise lengths with excellent straightness and consistent mechanical properties. It streamlines downstream operations such as welding, forming, tying, and automated feeding, making it indispensable across fabricated metal products and the broader manufacturing of iron and steel wire goods. By removing coil set and delivering tight tolerances, it helps production teams stabilize cycle times and reduce scrap.

- Typical materials: low carbon (e.g., Q195 or as needed), galvanized, annealed wire, PVC coated finishes.

- Max Length: 19FT; Tensile Strength: 30KGS/mm²— 55KGS/mm².

- Mechanical targets: controlled tensile strength for forming/welding; straightness and length tolerance engineered for automated lines.

- End styles: blunt, chamfered; packaging: PE-wrapped bundles, crates, or palletized for safe handling.

Hebei Minmetals Co., Ltd. manufactures straight cut wire with a focus on repeatable quality and supply reliability. With careful surface preparation, accurate cutting, and inline inspection, our straightened wire feeds smoothly in robotic welders, mesh welders, and press brakes. For an automotive fixtures supplier, switching from in-house cutting to pre-cut bundles stabilized part length variation and simplified quality checks—a representative outcome of partnering with an experienced producer.

Benefits & Use Cases of Straight Cut Wire in Manufacturing of iron wire, steel wire and its products

Across iron and steel wire manufacturing, straight cut wire is a building block for welded mesh panels, display racks, fan guards, filter cages, construction ties, bale ties, formed hooks, frames, and hardware components. In construction supply, black-annealed cut straight wire is favored for tying rebar and bundling; in appliance and retail fixtures, bright or galvanized straightened wire supports welding and bending with clean surfaces and low spatter. Length accuracy and consistent metallurgy are essential when parts are automatically loaded or nested for repeat forming runs.

- Operational advantages: tight length tolerance improves fit-up; superior straightness reduces feeder jams and rework.

- Finish options: galvanized for corrosion resistance, black-annealed for pliability, bright finish for clean welding and uniform plating/painting.

- Process-ready: bundles are labeled by size/lot for traceability, enabling lean kitting and faster line changeovers.

Hebei Minmetals Co., Ltd. supports OEMs and metal fabricators with application-oriented customization—diameter, length, finish, and packaging—so the straight and cut wire you receive arrives production-ready. Our technical team collaborates on first-article validation, ensuring the wire aligns with your welding parameters, bend radii, and downstream surface requirements.

Cost, Maintenance & User Experience

Total cost of ownership favors pre-cut, straightened wire when you consider hidden costs in coil processing—labor for decoiling and shearing, scrap due to length variation, and unplanned downtime from feeder issues. With Hebei Minmetals’ straight cut wire, customers typically streamline takt time, simplify incoming inspection, and reduce changeovers. The result is a cleaner line setup and better part-to-part consistency, which supports higher first-pass yield and predictable scheduling.

- Durability & ROI: proper tensile selection minimizes breakage during forming; consistent surface lowers weld cleanup, improving throughput.

- Inventory efficiency: receiving wire in production lengths reduces WIP and handling, supporting lean initiatives.

- Maintenance: store indoors, off the floor, and dry; keep bundles wrapped; use light protective oil where appropriate to maintain surface integrity.

Feedback from fabricators in the metal products sector highlights smoother feeding in mesh welders and fewer stoppages in automated cells when using properly straightened wire. Procurement teams also value clear labeling, consistent lot quality, and reliable lead times—all factors that Hebei Minmetals Co., Ltd. prioritizes to support uninterrupted production.

Sustainability & Market Trends in manufacturing

Manufacturers are aligning with sustainability goals, favoring recyclable inputs and processes that reduce scrap and energy use. Steel wire is inherently recyclable, and using straight cut wire optimizes material utilization by delivering only the lengths required. Additionally, clean surfaces and consistent straightness can reduce secondary finishing and rework, helping lower total process emissions per finished part.

- Market trends: expansion of automated welding and forming lines; tighter dimensional expectations; resilient supply chain planning.

- Sustainable practices: emphasis on scrap reduction, recyclable packaging, and efficient logistics to cut transport-related impacts.

Hebei Minmetals Co., Ltd. integrates quality-focused straightening and cutting to minimize offcuts and defects, supporting customers’ waste-reduction targets. Our application guidance—material grade, finish, and length selection—helps engineers choose the most efficient route for their product, aligning performance with environmental objectives while keeping total cost competitive.

Conclusion on Straight Cut Wire from Hebei Minmetals Co., Ltd.

From welded mesh and fixtures to construction ties and formed components, straight cut wire—also known as straightened wire and straight and cut wire—delivers accuracy, reliability, and throughput for the fabricated metal products sector. Hebei Minmetals Co., Ltd. combines consistent quality with application-driven customization to keep your lines running efficiently and your parts within spec. Ready to optimize your supply?

- Contact us: email: marketing@hebeimetals.com

- Visit our website: https://www.hebeimetals.com

- Explore the product page: Straight Cut Wire