welded wire mesh sheets

10月 . 19, 2024 18:33

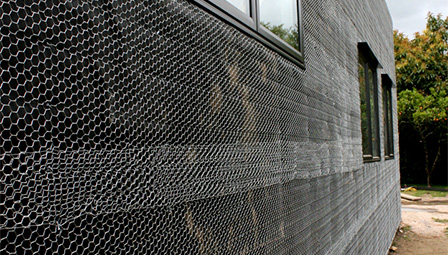

Understanding Welded Wire Mesh Sheets A Comprehensive Guide

Welded wire mesh sheets have become a popular choice in construction, agriculture, and various industrial applications due to their strength, durability, and versatility. Composed of high-quality steel wires that are welded together at each intersection, these sheets offer numerous benefits that make them suitable for a wide range of uses. In this article, we will explore the essential features, benefits, applications, and maintenance of welded wire mesh sheets.

Composition and Manufacturing

Welded wire mesh sheets are typically made from low carbon steel wire, though there are variations made from stainless steel and galvanized wire for enhanced corrosion resistance. The manufacturing process involves welding wires together at predetermined intervals, forming a grid-like structure. The spacing between the wires can vary based on the specific requirements, providing flexibility for different applications. The sheets are then cut to size, often available in standard dimensions, though custom sizes can be ordered to meet specific project needs.

Key Features

One of the standout features of welded wire mesh sheets is their structural integrity. The welding process creates strong joints, resulting in a mesh that can withstand significant loads and stresses. This makes them an ideal choice for reinforcing concrete structures, where the mesh acts as a support system to increase tensile strength. Additionally, the uniform spacing of the wires provides a level of stability and predictability, essential for various engineering applications.

Benefits of Welded Wire Mesh Sheets

1. Strength and Durability One of the foremost advantages of welded wire mesh sheets is their inherent strength. They can endure harsh environmental conditions and physical stresses, making them suitable for both indoor and outdoor uses.

2. Cost-Effectiveness Compared to other reinforcing materials, welded wire mesh sheets offer a more economical solution. They can reduce labor costs since they are easy to handle and install, especially in larger projects.

3. Versatility These sheets can be employed in a multitude of applications, from foundation reinforcement in buildings to fencing, cages, and agricultural uses. This versatility makes them an invaluable component in diverse sectors.

welded wire mesh sheets

4. Ease of Installation The pre-cut sheets can be easily laid out and tied in place during the concrete pouring process, streamlining construction operations and reducing project timelines.

5. Reduced Cracking in Concrete By providing evenly distributed support within the concrete, welded wire mesh sheets help minimize cracking and improve the longevity of structures.

Applications

The applications of welded wire mesh sheets are vast. In construction, they are commonly used for reinforcing concrete slabs, foundations, walls, and driveways. These sheets are also effective in creating security fencing for properties, livestock enclosures, and storage areas. In the agricultural sector, they are often used to construct animal enclosures, trellises for climbing plants, and protective barriers for crops.

In addition to traditional uses, welded wire mesh sheets have also found their place in the manufacturing sector, where they are employed in the production of shelves, partitions, and storage racks. The flexibility of design allows manufacturers to create specialized solutions tailored to specific needs.

Maintenance and Longevity

While welded wire mesh sheets are designed to be durable, proper maintenance is still essential to maximize their lifespan. Regular inspections for signs of rust or corrosion, especially in outdoor settings, can help identify potential issues early on. Additionally, using protective coatings can enhance the sheets' resistance to the elements.

When used in concrete applications, the mesh should be embedded properly to avoid exposure to moisture, which can lead to corrosion over time. For outdoor fencing or agricultural uses, periodic cleaning to remove dirt and debris will help maintain both appearance and functionality.

Conclusion

Welded wire mesh sheets represent a practical and effective solution across various industries. With their strength, versatility, and cost-effectiveness, they continue to be a preferred choice for builders, farmers, and manufacturers alike. Understanding their features and applications can aid in making informed decisions, ultimately leading to successful project outcomes. Whether used in construction, fencing, or agriculture, welded wire mesh sheets offer lasting solutions to strengthen and support various structures and environments.