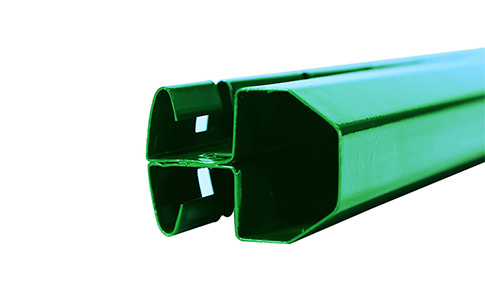

10 t post

نوفمبر . 17, 2024 01:55

The Impact of 10% Tolerance Post A Comprehensive Exploration

In the vast landscape of manufacturing and engineering, precision is paramount. One such principle that has garnered significant attention is the concept of a 10% tolerance post. But what does this mean, and why is it critical in design and production? To understand its importance, we need to delve into the definition, implications, and real-world applications of this tolerance standard.

At its core, a 10% tolerance post refers to the allowable variation or deviation from a specified dimension or characteristic of a component or system. In practical terms, if a component is designed to be 100 units, a 10% tolerance allows it to measure anywhere between 90 to 110 units. This flexibility is vital in the manufacturing process, where perfect accuracy is often unattainable due to various factors such as material properties, machine calibration, and human error.

However, the implications of a 10% tolerance extend beyond just numbers. They serve as a crucial balancing act between quality control, production efficiency, and cost management. The application of such tolerance levels is prevalent in numerous industries, including automotive, aerospace, electronics, and construction, where the fit and functionality of components directly impact safety and performance.

The Importance of Tolerances in Manufacturing

Manufacturers rely on tolerances to minimize waste and ensure that their products meet quality standards without incurring excessive costs. A tighter tolerance requires more meticulous production techniques and quality assurance processes, which can significantly raise manufacturing costs. On the other hand, a more lenient tolerance, such as the 10% standard, can reduce production complexities, enhance throughput, and allow for a broader range of materials and manufacturing processes.

For instance, in the automotive industry, components must often conform to specific performance standards. A 10% tolerance can provide the flexibility necessary for parts like engine components, where slight variances can accommodate thermal expansion and contraction during operation. This adaptability ensures optimal performance and longevity, which are essential for consumer safety and satisfaction.

Quality Control and Assurance

10 t post

While a 10% tolerance allows for some degree of flexibility, quality control measures must still be firmly in place. Organizations implement rigorous testing and inspection protocols to ensure that products fall within the acceptable tolerance range. Techniques such as statistical process control (SPC) and Six Sigma methodologies are often employed to monitor manufacturing processes and maintain product quality.

These quality assurance systems not only catch deviations but also provide insights into production efficiency. By analyzing data and trends, companies can identify areas for improvement, thus reducing waste and enhancing overall productivity. Consequently, this aligns with the goals of lean manufacturing, where waste reduction and continuous improvement are a priority.

Real-World Applications

The 10% tolerance post is particularly relevant in industries where safety and functionality are non-negotiable. In construction, for example, tolerances must be strictly adhered to for structural integrity. A small deviation in dimensions can have significant consequences, potentially compromising safety. Therefore, architects and engineers often employ a 10% tolerance to ensure that materials can accommodate minor deviations during assembly without sacrificing stability.

In the electronics industry, the advent of miniaturization has brought about new challenges. Tolerances in microfabrication require careful consideration, as even a 10% variance can lead to substantial performance differences in microchips and circuit boards. Engineers must balance the need for precision with the realities of production capabilities, often leading to innovations in materials and methods.

Conclusion

In conclusion, the concept of a 10% tolerance post is integral to modern manufacturing and engineering practices. It serves as a vital framework that allows for flexibility while ensuring that quality and safety standards are upheld. As industries continue to evolve, the principles behind tolerances will adapt, fostering innovations that reflect the demands of contemporary design and production. Understanding and implementing these tolerances not only enhances efficiency but also leads to better products that meet consumer expectations, ultimately driving progress in technology and industry.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution