High Performance 50 Mesh Screen for Efficient Filtration and Sorting Applications

أكتوبر . 12, 2024 07:48

The Versatility and Importance of 50% 20 Mesh Screens

In various industries, the importance of effective filtration and separation cannot be overstated. Whether it is in agriculture, mining, or the food industry, the right mesh screen can significantly influence the efficiency of operations. One particular type of mesh screen that has garnered attention is the 50% 20 mesh screen. This article will delve into the features, applications, and advantages of using a 50% 20 mesh screen in different fields.

Understanding Mesh Screens

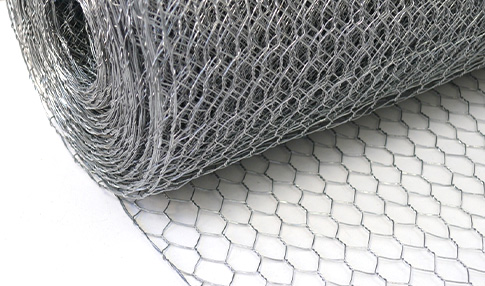

Before discussing the specifics of the 50% 20 mesh screen, it is vital to comprehend what mesh screens are. A mesh screen is made up of interwoven fibers or wires, creating openings of specified sizes. These screens are categorized by their mesh size, which refers to the number of openings per linear inch. For instance, a 20 mesh screen has 20 openings per inch and is typically used for medium filtration tasks.

The designation 50% refers to the open area of the screen, indicating that 50% of the screen's surface is free for air or liquid to pass through. This characteristic makes it exceptional for applications that require efficient flow while maintaining a level of filtration.

Applications of 50% 20 Mesh Screens

The 50% 20 mesh screen is versatile and can be utilized across various sectors

1. Agriculture In agriculture, these screens are commonly used in irrigation systems to prevent clogs in pipes and emitters. By filtering out debris and larger particles, these screens ensure that water flows freely to crops, promoting healthy growth and optimizing water usage.

2. Mining In the mining industry, the 50% 20 mesh screen plays a critical role in the processing of minerals. It helps separate larger rocks from smaller particles, facilitating the extraction process. The ability to control the size of material that passes through the mesh can significantly enhance the efficiency of mineral recovery processes.

3. Food and Beverage The food industry relies heavily on filtration for both quality and safety. The 50% 20 mesh screen is used in various stages of food processing, such as filtering juices, oils, and other liquids. The precise mesh size ensures that unwanted solids are removed, resulting in a cleaner and more palatable product.

50 mesh screen

4. Wastewater Management In wastewater treatment plants, efficient filtration is paramount. The 50% 20 mesh screen helps remove larger solids before they enter more sensitive filtration stages, protecting pumps and other equipment from damage caused by debris.

5. Pharmaceuticals In pharmaceutical manufacturing, maintaining product purity is crucial. The 50% 20 mesh screen ensures that unwanted particles are filtered out during the production process, thereby adhering to regulatory standards and ensuring consumer safety.

Advantages of 50% 20 Mesh Screens

The use of a 50% 20 mesh screen offers several advantages

- Efficiency With its balanced open area and mesh size, this screen allows for optimal flow rates while effectively filtering out unwanted materials. This efficiency translates to cost savings and improved productivity in industrial operations.

- Durability Typically made from robust materials such as stainless steel, 50% 20 mesh screens are designed to withstand harsh environments and prolonged use. Their durability ensures they can handle high volumes without compromising integrity or performance.

- Versatility The wide range of applications means that industries can utilize these screens in various processes, eliminating the need for multiple different types of screens and simplifying inventory management.

- Ease of Maintenance Cleaning and maintaining 50% 20 mesh screens is relatively straightforward, allowing for quick turnaround times and minimal downtime in operations.

Conclusion

The 50% 20 mesh screen is an essential tool across multiple industries due to its unique balance of filtration efficiency and flow capability. Its applications in agriculture, mining, food processing, wastewater management, and pharmaceuticals demonstrate its versatility and importance. As industries continue to seek ways to improve efficiency and maintain quality standards, the value of such specialized mesh screens will undeniably grow. Embracing technologies and materials that enhance filtration processes will pave the way for more sustainable and productive operations in the future.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution