Exploring the Innovations of Cyclonic Mesh Technology for Enhanced Performance and Durability

أكتوبر . 13, 2024 09:59

Exploring the Cyclonic Mesh A Breakthrough in Filtration Technology

In an era where environmental sustainability and advanced filtration technology are imperative, the concept of cyclonic mesh has emerged as a groundbreaking solution for various industries. This innovative technology combines the principles of cyclone separation with advanced mesh design to enhance filtration efficiency, reduce pressure drops, and ensure the effective removal of particulate matter from gases and liquids.

The Principle of Cyclonic Separation

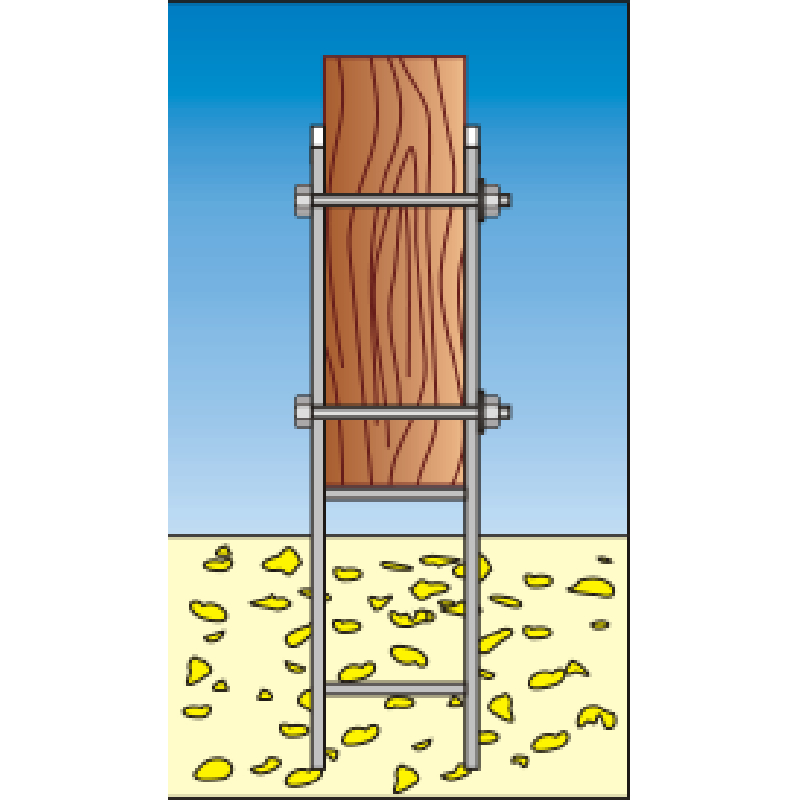

At the heart of cyclonic mesh technology is the mechanism of cyclonic separation. This process relies on the centrifugal force generated when a fluid flows through a cylindrical vessel. As the fluid enters the cyclone, it spirals downwards, causing heavier particles to be thrown outwards and collected at the bottom while the lighter fraction exits at the top. This separation method has long been used in various applications, from industrial dust collection to liquid separation in the oil and gas sector.

However, traditional cyclonic systems can face limitations when it comes to finer particulate filtration. Herein lies the innovation of cyclonic mesh—a finely woven material that enhances the separation process by acting as an additional barrier against smaller particles. This dual-layer approach not only captures a broader range of particulates but also maintains a lower pressure drop, promoting energy efficiency.

Advantages of Cyclonic Mesh

The advantages of cyclonic mesh over conventional filtration methods are substantial

1. Enhanced Filtration Efficiency The combination of cyclone principles and the mesh structure allows for superior removal of contaminants. This is particularly important in industries such as pharmaceuticals, food processing, and chemical manufacturing, where purity standards are critical.

2. Reduced Maintenance Costs Traditional filtration systems often require frequent replacements and maintenance due to clogging and wear. The self-cleaning properties of cyclonic mesh reduce the frequency of maintenance interventions, leading to lower operational costs.

cyclonic mesh

3. Versatile Applications Cyclonic mesh technology finds applications across various fields, including air pollution control, wastewater treatment, and even in HVAC systems. Its adaptability makes it a valuable solution for addressing diverse filtration challenges.

4. Environmental Sustainability By improving filtration efficiency and reducing waste, cyclonic mesh contributes to environmental sustainability goals. Industries adopting this technology can reduce their carbon footprint and promote cleaner production processes, aligning with global efforts to combat climate change.

Applications in Industry

The cyclonic mesh technology has the potential to revolutionize several sectors. For example, in the food and beverage industry, it can improve the quality of products by ensuring that no unwanted particles contaminate the final output. In chemical manufacturing, it plays a crucial role in maintaining product purity and compliance with regulatory standards.

Moreover, the renewable energy sector increasingly relies on cyclonic mesh for the filtration of biofuels and other sustainable energies, ensuring that production processes remain efficient and environmentally friendly. As industries strive to meet increasing regulatory compliance and eco-friendly standards, the adoption of this technology is expected to grow significantly.

Future Developments

As the demand for more efficient and sustainable filtration methods continues to rise, research and development in cyclonic mesh technology are likely to advance further. Innovations may focus on enhancing material properties to improve chemical resistance and mechanical strength, thus broadening the application range. Additionally, integrating smart technologies with cyclonic mesh systems will enable real-time monitoring and automated maintenance, ensuring optimal performance.

In conclusion, the advent of cyclonic mesh technology marks a significant milestone in filtration advancements. With its combination of efficiency, cost savings, versatility, and environmental benefits, it presents a compelling case for industries looking to enhance their operational processes. As technology evolves and industries continue to pursue sustainable practices, cyclonic mesh is poised to play a critical role in shaping the future of filtration solutions.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution