Durable Wire Garden Fence Solutions - Secure & Stylish

أغسطس . 03, 2025 03:00

The global fencing market has witnessed a significant surge with a projected CAGR of 5.2% (2021-2027), fueled majorly by landscaping initiatives, urban development projects, and growing demand for security solutions. The Wire Garden Fence emerges as an industry benchmark—combining durable materials, advanced manufacturing, and customization to cater to both decorative and highly resilient enclosure needs.

- 2023 global wire fencing market size: USD 8.7 Billion[1]

- Major end-users: Residential, Horticulture, Municipal, Industrial (Oil & Gas, Metallurgy, Water Treatment, Parks, Zoos)

- Regulatory standards: ISO 9001, ISO 1461 for galvanization, ANSI/BIFMA X5.6, and country-specific environmental codes.

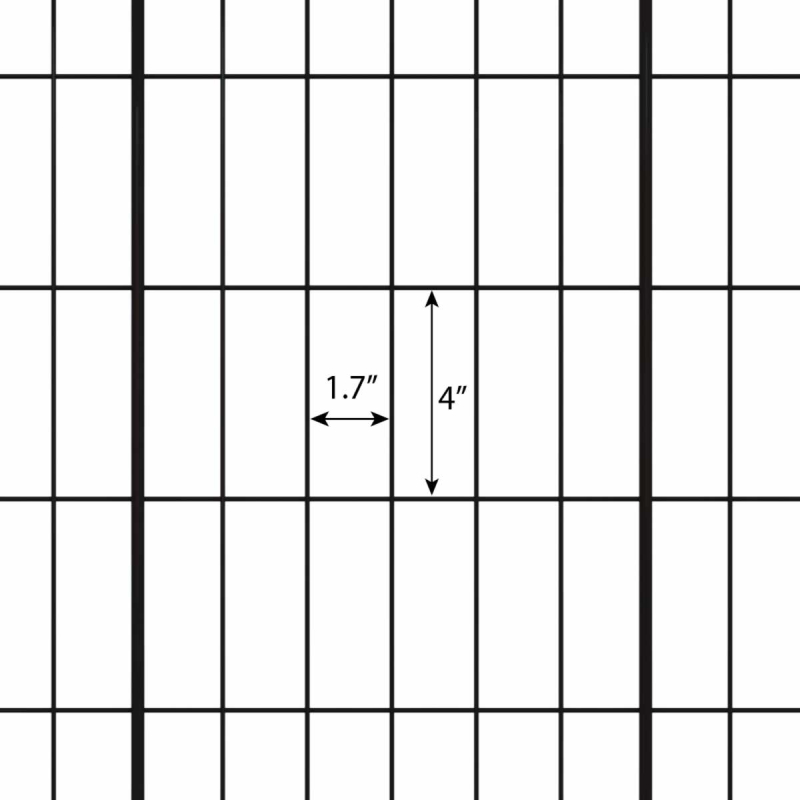

Wire Garden Fence: Technical Parameters & Specification Table

Wire Garden Fence products are characterized by their mesh structure, wire diameter, coating type, and panel dimensions, each impacting performance and cost-utility in different environments.

| Specification | Standard Model | Heavy-duty Model | Custom Model |

|---|---|---|---|

| Mesh Size | 50 x 50 mm | 25 x 25 mm | 15 - 100 mm (customizable) |

| Wire Diameter | 2.5 mm | 3.5 mm | 1.5 - 6.0 mm (customizable) |

| Panel Height | 1.0 m / 1.2 m | 1.5 m / 2.0 m | 0.5 - 3.0 m |

| Panel Length | 2.0 m | 2.5 m | 1.0 - 3.0 m |

| Surface Treatment | Hot-dip Galvanized | PVC Coated Galvanized |

Stainless Steel / Customized |

| Service Life | > 10 years | > 15 years | Up to 25 years |

| Applicable Standards | ISO 9001:2015, ISO 1461 | ANSI/BIFMA X5.6 | ISO, EN, Customized |

Wire Garden Fence Manufacturing Process: Step-by-Step Flow

The production of Wire Garden Fence follows stringent process controls and advanced engineering to ensure top-tier mechanical properties and corrosion resistance. Below, a detailed flowchart demonstrates the complete process:

(Q195, Q235, 304 SS Wire)

(Automatic Resistance Weld, CNC Press)

(Hot-dip Galv., Electro-Galv., PVC or Powder Coating)

(Dimensional, Welding, Coating Thickness, Salt Spray per ISO 9227)

(Palletized/Customized)

-

Process Highlights:

- Material: Available in low-carbon steel (Q195/Q235), galvanized, 304 stainless steel for harsh industrial applications.

- Surface Protection: Hot-dip galvanize up to 300g/m2 zinc layer; powder/PVC coating in RAL colors.

- Inspection: Each batch tested with ISO 9227 salt spray (>500hrs), ensuring 10+ years of anti-corrosion in open-air.

Industry Trends & Manufacturer Comparison: Wire Garden Fence

As urban landscaping and facility safety become paramount, Wire Garden Fence solutions are adapting. Here’s an analysis comparing top global suppliers and product types:

| Manufacturer | Main Market | Certifications | Delivery Cycle | Customization Capability |

|---|---|---|---|---|

| Hebei Metals | Europe, North America, APAC | ISO 9001, SGS, CE | 15-25 days | Mesh, Color, Height, Logo branding |

| Betafence | EU, Africa | ISO 9001, ISO 14001 | 30-40 days | Medium |

| Deer Fence USA | North America | ASTM, FDA (coating) | 20-35 days | Eco & Wildlife |

| Eastern Wire | Southeast Asia | ISO 9001 | 25-40 days | Standard |

- Lead time is a key factor. Hebei Metals leverages CNC automation to offer the fastest turnaround in custom orders.

- Certifications: Always ensure Wire Garden Fence products meet ISO/ANSI or project-specific standards.

Data Visualization: Market Share, Performance Comparison

Hot-dip Galvanized

Stainless Steel

Customization Solutions: Adapting Wire Garden Fence for Every Scenario

At Hebei Metals, customization aligns with application-specific requirements and global compliance standards:

- Mesh Design & Height: Security fencing—select tighter mesh (e.g., 25x25 mm); Decorative/ornamental—select scalloped or curved tops.

- Material/Finish: Coastal/petrochemical plants require marine-grade stainless (304/316), exceeding ISO 1461 salt spray; Public parks prefer UV-stable colored PVC for aesthetics.

- Accessories & Posts: Anti-climb posts, removable sections for events, welded gates, branded sign plates.

- OEM/ODM Options: Size, mesh pattern, finish, integrate with solar lights, RFID tags for smart facility management.

Application Scenarios: Why Choose Wire Garden Fence?

- Urban Landscaping: Demarcating park boundaries, playgrounds, green belts—designed for aesthetics and resilience.

- Industrial Enclosures: Refinery perimeters, waste management, petrochemical plants—extra corrosion resistance (hot-dip galv., SS304).

- Agricultural Protection: Animal fencing, crop & orchard protection—opt for zinc/aluminum alloy coated wire for longevity.

- Infrastructure: Water treatment works, roads, substation barriers—integration with CCTV, anti-lift fasteners.

Case Study: Municipal Park Transformation, Rotterdam, NL

- Project: 2,000m Wire Garden Fence installation for urban revitalization.

- Challenges: Proximity to sea air (high corrosion risk), need for playful aesthetics with safety.

- Hebei Metals Solution:

- 304SS core, powder-coated in custom RAL 6017 green

- Child-safe mesh ends (rounded knots)

- ISO 9227 certified salt spray resistance (800 hours+)

- Feedback: 40% decrease in vandalism, 15-year projected lifespan, praised for finish quality by city council.

FAQ: Wire Garden Fence Professional FAQ

Quality Control, Certifications & Customer Support

- Global Certification: Products certified to ISO 9001:2015, ISO 1461 (coating), CE Mark, SGS, TÜV.

- Partnered Clients: Trusted by Siemens, Aramco, Sinopec, IKEA, and municipal engineering departments.

- QC Protocol: Raw material inspection, continuous weld monitoring, 100% salt spray test, coating thickness via X-ray fluorescence.

- Warranty: 10–20 years—anti-corrosive, color retention, structural warranty (details by contract).

- After-sales support: 24/7 online support, field installation guidance, free spare parts for mechanical failure within warranty.

Delivery & Packaging

- Palletized, plastic film-wrapped, with steel strapping for international transit

- Custom logo/brand plates available

Environmental Compliance

- All Wire Garden Fence products comply with EU REACH, RoHS, and are produced in ISO 14001-certified facilities.

References & Further Reading

- Global Fencing Market Analysis (MarketsandMarkets)

- ISO 1461: Hot Dip Galvanized Coatings on Fabricated Iron and Steel Articles

- ASTM F567 Standard Practice for Installation of Chain-Link Fence

- Industry Forum: Garden Fence Talk

- FenceWeek: Industry News & Insights