metal mesh cloth

نوفمبر . 25, 2024 09:39

Exploring Metal Mesh Cloth A Versatile Material for Modern Applications

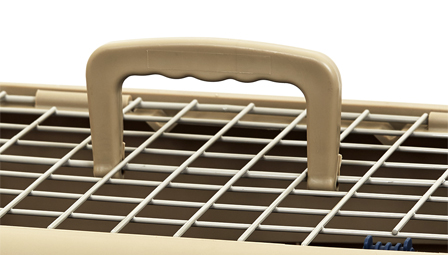

Metal mesh cloth, often referred to simply as metal mesh, is increasingly gaining popularity across various industries due to its unique combination of strength, flexibility, and versatility. This innovative material consists of woven or welded metal strands that can be used in a multitude of applications, ranging from architectural design to industrial filtration. In this article, we will delve into the characteristics, uses, and benefits of metal mesh cloth, highlighting why it is becoming an essential component in many fields.

Characteristics of Metal Mesh Cloth

One of the defining features of metal mesh cloth is its robust structure, which typically consists of stainless steel, aluminum, or other alloys. These materials not only provide durability but also offer resistance to corrosion and high temperatures, making metal mesh suitable for various environments. The weaving or welding technique employed in creating metal mesh leads to a lightweight yet strong product, which can be easily manipulated to fit specific needs.

The mesh's open design allows for airflow and light penetration while still providing a certain degree of privacy and safety. Furthermore, the degree of openness in metal mesh can be customized during the manufacturing process, allowing for fine-tuning based on the intended application. This versatility extends to different patterns and weaves, offering a range of aesthetic options that are ideal for decorative purposes.

Applications of Metal Mesh Cloth

Metal mesh cloth finds application in an array of industries, reflecting its versatility. In the architectural sector, it is commonly used as a façade element in modern buildings. Architects utilize metal mesh to create striking exterior designs that not only enhance visual appeal but also improve energy efficiency by controlling solar heat gain. Similarly, metal mesh is employed in interior design for decorative screens, railings, and partitions that allow for both style and functionality.

metal mesh cloth

In the industrial realm, metal mesh cloth is indispensable for filtration systems, used to separate particles in liquids and gases. Its ability to withstand high pressure makes it ideal for use in petrochemical, food processing, and water treatment applications. The aerospace and automotive industries also benefit from metal mesh components for their lightweight nature and structural integrity, contributing to improved performance and fuel efficiency.

Metal mesh is applied in the manufacturing of safety equipment, such as protective clothing and gear, providing workers in hazardous environments with necessary protection while allowing for breathability and comfort. Additionally, the electrical industry frequently employs metal mesh for electromagnetic interference shielding, ensuring optimal performance of electronic devices.

Benefits of Metal Mesh Cloth

The advantages of metal mesh cloth are numerous. Its durability means that products made from metal mesh tend to have a longer lifespan, reducing replacement costs and waste. Additionally, metal mesh can be easily cleaned and maintained, which is crucial in environments requiring high hygiene standards, such as hospitals and food processing facilities.

Moreover, metal mesh is an eco-friendly choice. Metal is recyclable, and using metal mesh contributes to sustainable practices as it can be repurposed without significant degradation of quality. This aligns with the growing demand for sustainable materials in a world increasingly focused on reducing environmental impact.

In summary, metal mesh cloth is not just a functional material; it is a versatile solution with broad applications and significant benefits. Its strength, adaptability, and aesthetic appeal make it an invaluable asset in various fields, paving the way for innovative designs and efficient industrial processes. As industries continue to evolve, metal mesh cloth's role is only set to expand, making it a material worth investing in for the future.