12 gauge iron wire

Верас . 03, 2024 16:23

Understanding 12 Gauge Iron Wire Properties, Uses, and Applications

When it comes to the world of wire, one of the most commonly discussed types is the 12 gauge iron wire. The gauge of a wire, specifically in the American Wire Gauge (AWG) system, indicates its diameter. A 12 gauge wire has a diameter of approximately 2.05 mm (0.081 inches), making it a robust and versatile choice for a variety of applications.

Properties of 12 Gauge Iron Wire

Iron wire is primarily valued for its strength and durability. The 12 gauge wire, in particular, stands out due to its thicker diameter, which allows it to handle significant tension and weight loads. Iron, known for its tensile strength, can be used in diverse environments, from construction sites to crafting projects.

Another significant property of 12 gauge iron wire is its malleability. The wire can be bent and shaped into different forms without breaking, which makes it ideal for various applications that require twisting, coiling, or forming into specific shapes. Aluminum or copper wires, while lighter, do not always possess the same level of strength, making iron wire a go-to option for demanding tasks.

Uses of 12 Gauge Iron Wire

The applications of 12 gauge iron wire are numerous and varied

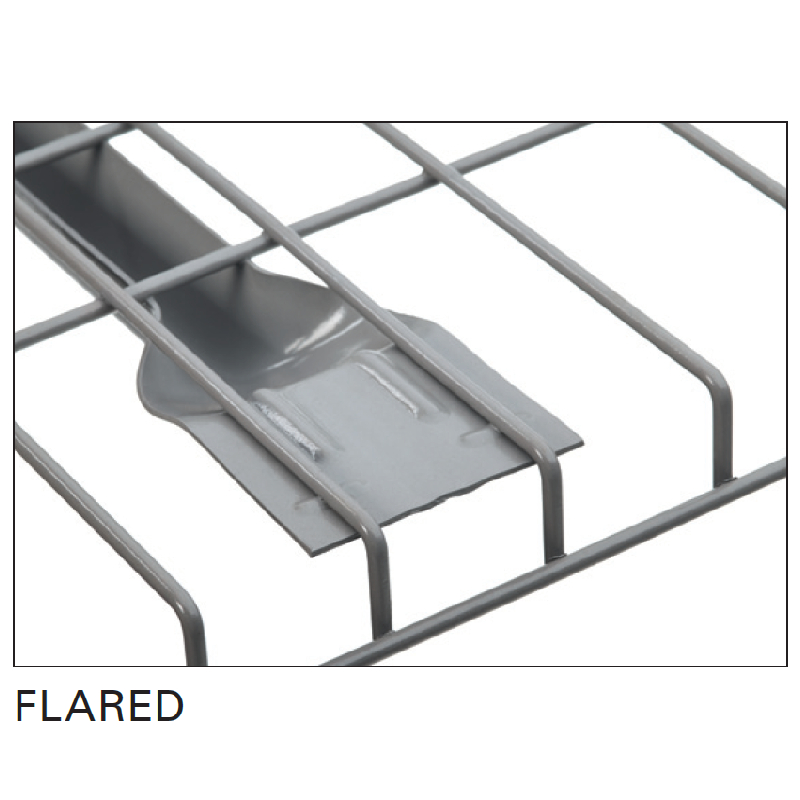

. One of the most common uses is in the construction industry, where it serves as reinforcement in concrete and masonry works. The wire can be used in making reinforcing cages for columns and beams, ensuring that structures can bear loads effectively without compromising integrity.12 gauge iron wire

Additionally, 12 gauge iron wire is widely utilized in fencing. Its thickness provides a sturdy structure that is less prone to bending or breaking under stress, making it suitable for agricultural, residential, and commercial fencing. It can withstand the elements better than thinner wire, which can corrode or deteriorate more readily.

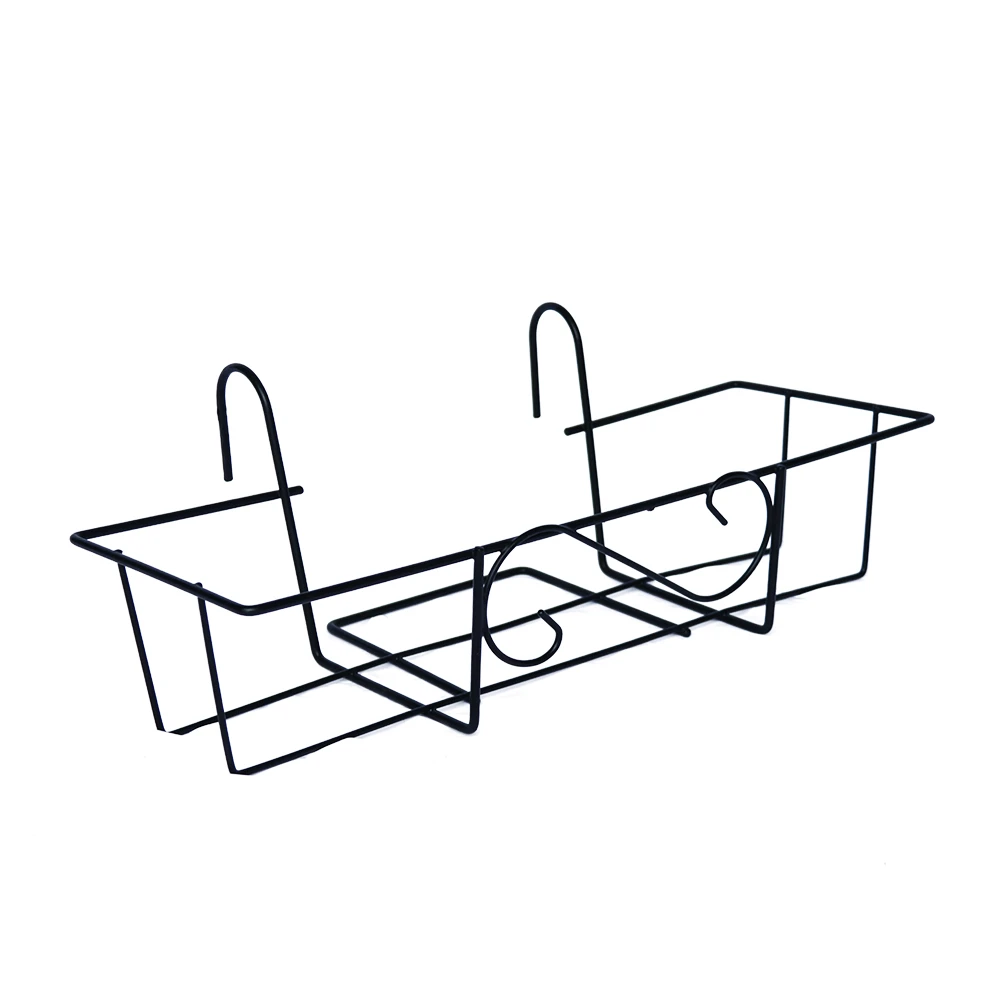

In the realm of crafting and DIY projects, 12 gauge iron wire offers versatility. Crafters use it to create various items, including sculptures, jewelry, and decorative pieces. Its ability to be easily manipulated makes it a favorite among artisans aiming to create unique designs and structures.

Advantages and Limitations

One significant advantage of 12 gauge iron wire is its cost-effectiveness. Iron wire is typically more affordable than alternatives made from other metals like stainless steel or high-grade alloys. Furthermore, its durability means that it can operate efficiently for extended periods without needing replacement or repair.

However, there are limitations to consider. Although iron wire is strong, it is also susceptible to rust and corrosion if not properly treated or coated. Therefore, for applications exposed to moisture or extreme conditions, using galvanized or coated iron wire is recommended to prevent deterioration.

Conclusion

In summary, 12 gauge iron wire is a durable and robust tool suitable for various applications in construction, crafting, and fencing. Its thickness and strength make it a favored choice for projects requiring stability, while its malleability allows for easy manipulation into various shapes. While it does pose some limitations related to corrosion, the advantages of cost-effectiveness and strength make it an essential material in both professional and DIY realms. Whether you are reinforcing a structure or creating an artistic masterpiece, 12 gauge iron wire proves to be an invaluable resource.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution