304 Stainless Steel Mesh Applications and Benefits for Various Industries

Каст . 15, 2024 21:50

The Versatility of 304 Stainless Steel Mesh

304 stainless steel mesh is a widely used material in various industries due to its exceptional properties and versatility. As a member of the austenitic stainless steel family, 304 stainless steel is known for its corrosion resistance, high tensile strength, and excellent formability, making it an ideal choice for diverse applications.

One of the most significant advantages of 304 stainless steel mesh is its outstanding resistance to rust and corrosion. This property is a result of the high nickel and chromium content in the alloy, which forms a passive layer on the surface. This layer protects the steel against rusting, even in harsh environments and under exposure to moisture. Consequently, 304 stainless steel mesh is commonly used in applications where the material is exposed to extreme conditions, such as marine environments, chemical processing plants, and food processing facilities.

The strength and durability of 304 stainless steel mesh make it suitable for various applications across multiple sectors. Its high tensile strength ensures that the mesh can withstand significant stress without breaking or deforming. This characteristic is particularly beneficial in construction and architectural applications, where the integrity of the mesh is paramount. For example, 304 stainless steel mesh is often used in concrete reinforcement, providing additional strength and support to structures.

In addition to its structural applications, 304 stainless steel mesh is popular in the food and beverage industry. Its corrosion resistance and ability to maintain hygiene standards make it an ideal choice for equipment used in processing and storing food. Stainless steel mesh is easy to clean and does not harbor bacteria, making it compliant with food safety regulations. Whether used for filters, sieves, or cooking equipment, 304 stainless steel mesh helps maintain the quality and safety of food products.

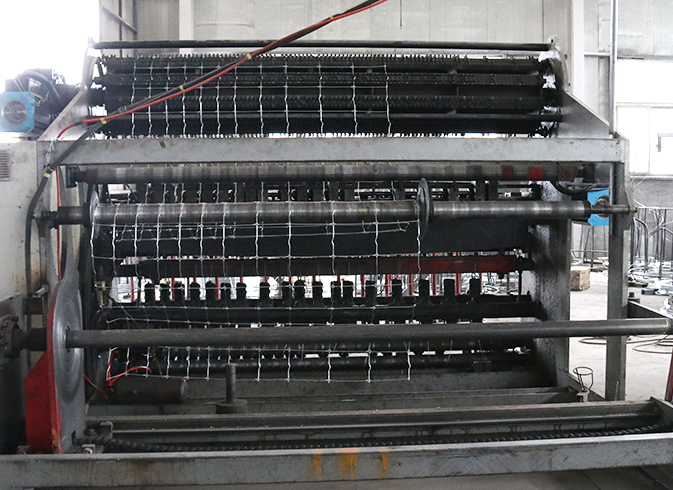

304 stainless steel mesh

Another area where 304 stainless steel mesh excels is filtration. The mesh can be manufactured with varying hole sizes and wire diameters, allowing it to be tailored for specific filtration needs. Industries such as pharmaceuticals, petrochemicals, and water treatment utilize 304 stainless steel mesh for filtering liquids and gases. Its durability ensures longevity in demanding applications, while its non-reactive properties prevent contamination.

The architectural and design sectors also make use of 304 stainless steel mesh for aesthetic purposes. The sleek, modern appearance of stainless steel lends itself well to contemporary design. Architects often use 304 stainless steel mesh as decorative screens, facades, and railing systems, allowing for creativity while still providing safety and functionality. The mesh's ability to let light through while simultaneously offering privacy makes it a popular choice in both residential and commercial projects.

Moreover, the ease of fabrication and installation of 304 stainless steel mesh adds to its appeal. It can be easily cut, welded, or shaped to fit specific design requirements. This adaptability allows manufacturers and designers to create custom solutions tailored to their needs, further expanding the potential applications of 304 stainless steel mesh.

In conclusion, 304 stainless steel mesh is a highly versatile material with applications spanning numerous industries. Its corrosion resistance, strength, durability, and aesthetic appeal make it an ideal choice for construction, food processing, filtration, and design. As industries continue to innovate and focus on sustainability and quality, the demand for 304 stainless steel mesh is likely to grow, solidifying its role as a vital material in modern manufacturing and construction. Whether it's providing structural support or enhancing visual aesthetics, 304 stainless steel mesh remains a material of choice for those seeking reliability and excellence.