Durable and Versatile Plain Weave Wire Mesh for Various Industrial Applications and Uses

жнів . 15, 2024 04:39

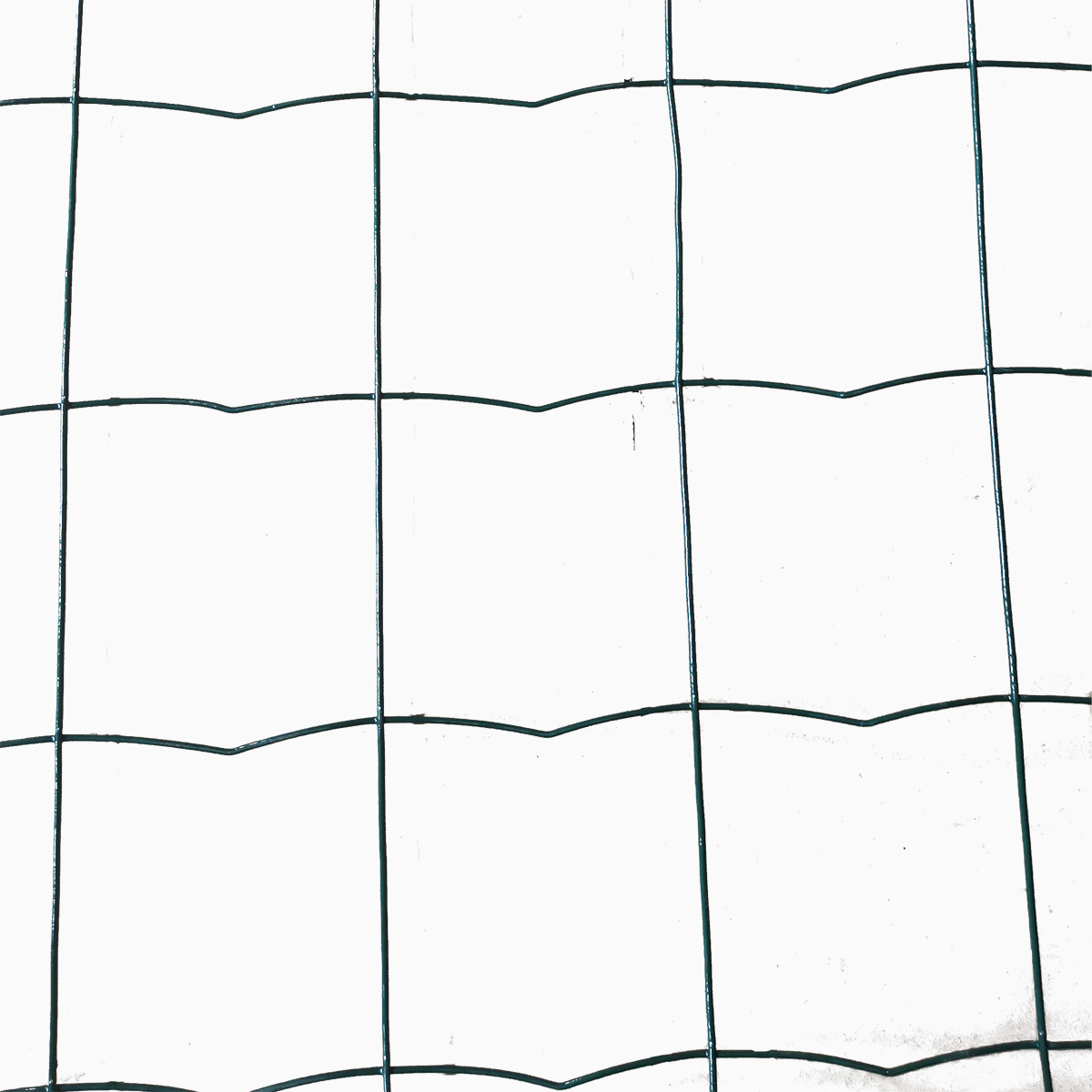

Understanding Plain Weave Wire Mesh A Versatile Solution for Various Applications

Plain weave wire mesh is one of the most widely utilized forms of wire mesh due to its simple yet effective design and numerous applications across various industries. Comprising interwoven wire strands that create a grid-like structure, plain weave wire mesh offers versatility, strength, and reliability, making it a preferred choice for many engineering and construction projects.

What is Plain Weave Wire Mesh?

At its core, plain weave wire mesh is made by weaving together wires in a specific pattern. In this formation, the wires run both horizontally and vertically across the mesh, creating a balanced and uniform pattern. This weaving technique results in openings that are square or rectangular, depending on the gauge and spacing of the wires used. The wires can be made from a variety of materials, including stainless steel, galvanized steel, copper, and aluminum. Each material offers different benefits in terms of strength, corrosion resistance, and suitability for specific environments.

Characteristics of Plain Weave Wire Mesh

One of the significant advantages of plain weave wire mesh is its structural integrity. The even distribution of stress across the mesh provides a strong surface that can handle considerable weight and pressure. Additionally, it is resistant to deformation, tension, and compression, which is vital in applications where durability is crucial.

Another key characteristic is its versatility. The open design allows for excellent ventilation and light transmission, making it a popular choice in areas requiring airflow while still providing a barrier, like fencing and grating. Its design also enables easy customization; mesh can be manufactured to a wide range of sizes, wire diameters, and openings, catering to the specific needs of a project.

plain weave wire mesh

Applications

The applications of plain weave wire mesh are extensive. In construction, it is commonly used for reinforcement in concrete and as support in walls, ceilings, and floors. The mesh helps to distribute loads evenly and enhances the tensile strength of the overall structure.

In the industrial sector, plain weave wire mesh plays a critical role in filtration and separation processes. Its ability to allow liquids and gases to pass through while filtering out larger particles makes it an essential component in many manufacturing environments, including food and beverage, pharmaceuticals, and chemical industries.

Moreover, plain weave wire mesh is frequently employed in architectural applications. It can be used for decorative facades, privacy screens, and safety barriers, combining aesthetics with functionality. The mesh provides security while allowing for creative designs that can elevate the visual appeal of a building.

Maintenance and Care

Maintaining plain weave wire mesh is relatively straightforward. Regular cleaning can help prevent build-up from environmental elements, especially in outdoor applications. Corrosion-resistant materials, such as stainless steel or galvanized wire, will require even less maintenance, ensuring longevity and performance.

In summary, plain weave wire mesh is a fundamental element in various industries due to its strength, versatility, and range of applications. Its simple yet effective design caters to numerous functional requirements, making it an indispensable resource in construction, industrial processes, and architectural designs. Whether for creating sturdy barriers or enabling filtration processes, plain weave wire mesh continues to play a critical role in fostering innovation and efficiency in multiple fields.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution