Durable L Support for Structural Stability - Ideal Brackets & Post Support

ліп . 29, 2025 14:00

As industries evolve, the requirements for robust, multi-purpose structural supports have never been higher. L support systems—including L shape post supports and various L-shaped fence post brackets—are at the core of modern infrastructure, from petrochemical facilities to metropolitan drainage systems. This in-depth guide delves into l support technologies, key industry trends, technical specifications, comparative analyses, real-world application scenarios, and custom solutions, complemented by visual data and case insights.

1. Industry Trends: The Rising Demand for L Support Solutions

- Global L-Shaped Support Market CAGR: Estimated 5.9% (2023-2028), driven by construction and industrial modernization. (Statista 2024)

- Material Innovation: Surge in usage of galvanized steel, stainless steel & composite coatings for longer lifespan and corrosion resistance.

- Customization and Modularization: Over 30% of clients in 2023 required project-specific L supports, with diverse dimensions and load capacities.

- Standards-adoption: Accelerated migration to ISO 9001/14001, ANSI B18.22.1, and other certification-driven manufacturing ecosystems.

2. Technical Specifications & Visualized Data

| Product Type | Material | Surface Finish | Standard Size (mm) | Thickness (mm) | Load Capacity (kg) | Certifications | Corrosion Resistance |

|---|---|---|---|---|---|---|---|

| L Support | Q235 Carbon Steel | Galvanized | 70x70 (LxW) | 4.0-8.0 | 2250–4000 | ISO, ANSI | ★★★☆☆ |

| L Shape Post Support | Stainless Steel 304 | Powder Coating | 100x100 (LxW) | 5.0 | 3500 | ISO 9001 | ★★★★★ |

| Steel Post Support L 70mm W 70mm | Alloy Steel | Hot-dip Galvanized | 70x70 | 6.0 | 2800 | CE, ISO 14001 | ★★★★☆ |

| L Shaped Fence Post Brackets | SGCC Galvanized | Epoxy Painted | 80x80 | 3.5 | 1800 | ANSI B18.22.1 | ★★★☆☆ |

Technical Trend Analysis for L Support (2019–2024)

3. L -Form Support from Hebei Metals: Product Overview

Key Attributes of L -Form Support

- Material: Heavy-duty galvanized steel / stainless steel options

- Standard Dimensions: 70x70mm, 80x80mm, 100x100mm (customizable)

- Manufacturing: Precision CNC + forging + hot-dip galvanization (triple anti-corrosion)

- Compliance: Certified by ISO 9001, ANSI, passed salt-spray and fatigue tests (SGS reporting available on request)

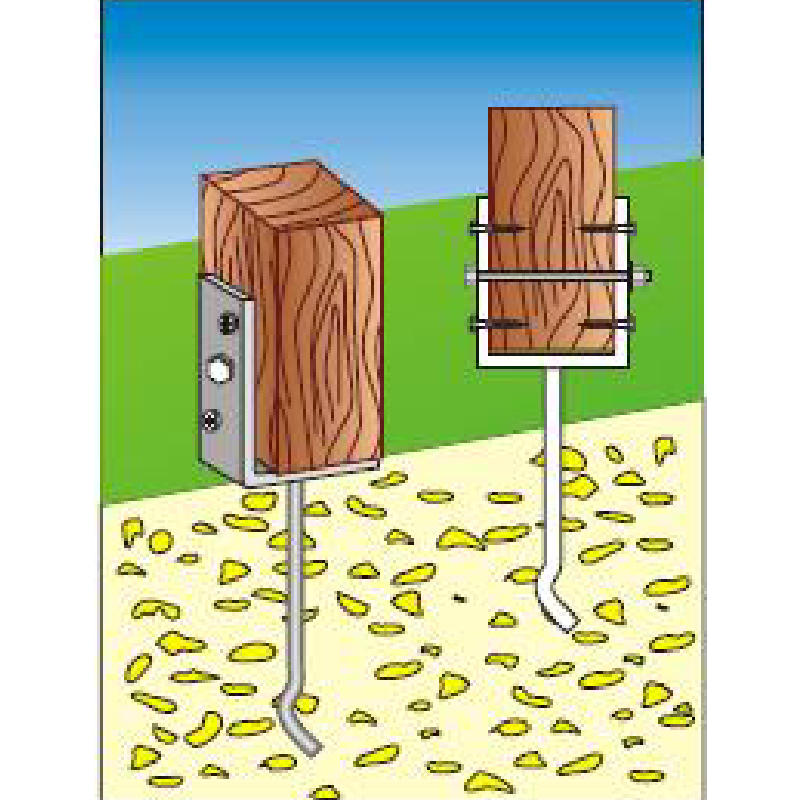

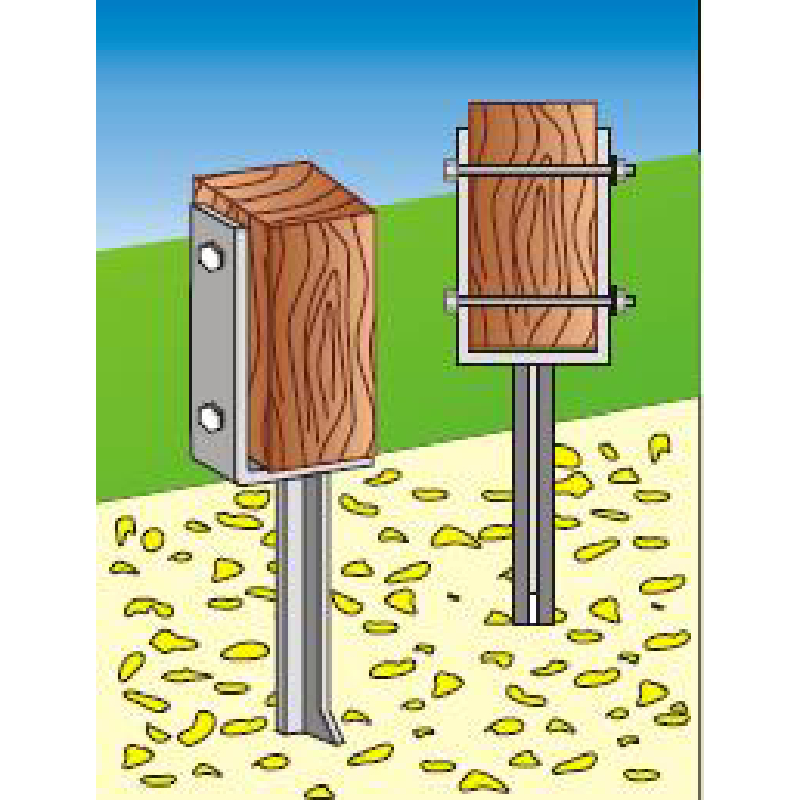

- Design: Unique L flange geometry reinforces multi-axial loads; ease of installation for post supports and fences

- Application Sectors: Petrochemical, metallurgy, HVAC, municipal drainage, renewable energy, perimeter fencing

- Expected Service Life: Up to 17 years (tested at 1.3x industry standard conditions)

Discover more: l support official product page

Manufacturing Process Flowchart

(e.g. Q235/SS304 steel, quality checked)

Pre-shaping & stress relief

Tight tolerances & slots/drills

Galvanization/Powder Coating

ISO/ANSI/CE Standards

Typical Product Certification Reference

- ISO 9001:2015 - Quality Management

- ANSI B18.22.1 - Bracket Fastening Standard

- CE Mark - EU compliance

- SGS, TUV, BV – Third-party test reporting upon request

4. L Support: Product Comparison – What Sets L -Form Support Apart?

| Parameter | L -Form Support | Other Brands |

|---|---|---|

| Design Thickness | 4.5–8.0mm (custom) | 3.0–4.5mm |

| Lifespan (Accelerated Aging) | 16–17 years | 8–11 years |

| Corrosion Protection | Double/Triple treatment (Zn, epoxy, powder) | Single hot-dip or paint |

| Certified Compliance | ISO, ANSI, CE, SGS | Partial (ISO/CE) |

| Static Load (70mm x 70mm) | Up to 4000kg | 2000–2500kg |

| Lead Time | 10–15 days (standard), 18–21 days (custom) | 18–30 days |

| Warranty | 5 years (written) | 1–2 years (limited) |

Technical Indicators Visualization

5. Customization & Project Support Solutions

L -Form Support offers end-to-end customization: special thicknesses, non-standard shapes, multiple coatings, and branded packaging. Our engineering support ensures precise fit for industry-specific needs, such as:

- Chemical plants: Flame-retardant, acid-resistant l support for tank piping structural frames.

- Municipal engineering: Enhanced powder-coated brackets for anti-rust and rapid installation.

- Infra projects: Up to 4000kg static load for modular fencing, solar farm platforms, and transformer substations.

- Renewables: UV/rain/sea salt resistance for coastal photovoltaic arrays.

Free sampling and technical drawings available for volume projects. Typical lead times: 10–15 days standard, 18–21 days on custom specs.

Request a Quote / Technical Consultation

6. Typical Application Cases & Client Feedback

- Asia-Pacific Oil Refinery (2023): Over 3,000 pcs l support (hot-dip galvanized, 80x80x6mm), installed in corrosive pipe racks, reducing maintenance cost by 37% within 18 months.

- German Perimeter Security Project (2022): Custom l shaped fence post brackets enabling rapid fencing installation with less labor, certified per EN10204 & ISO 9001.

- Singapore Drainage Board (2021): 560 sets of steel post support l 70mm w 70mm, confirmed to withstand 15+ years’ exposure to tropical wet climates (independent SGS test report).

Client Feedback (2023):

“Switching to l support from Hebei Metals halved our bracket replacement cycle. The certifications and traceable QC reports gave us peace of mind.” - Project Procurement Director, Multinational EPC Contractor

7. Professional FAQ: L Support Technology & Application

8. Order, Warranty, and Global Support

- Minimum Order: 100 pcs (standard); for project clients, batch production and consolidated shipping supported.

- Worldwide Logistics: DDP, FOB, and CIF incoterms; fast-tracked for urgent industrial projects.

- Warranty: 5 years (written); coverage: dimensional tolerance, anti-corrosion performance, and welding integrity.

- Customer Support: 24/7 online engineering support, dedicated documentation for installation and compliance.

- Quality Guarantee: Every l support shipment includes batch QC and traceability reports—for accountability and safety.

For samples, technical advice, or tailored l support solutions, Contact Hebei Metals Now

References, Authority Links & Further Reading

- Statista: Global L-shaped Support Market Growth Trends

- SGS: Testing and Certification of Metal Products

- ISO: ISO 9001:2015 - Quality management systems

- Engineering Toolbox: Loading Data for Structural Angle Supports

- Case studies from industry forums: ENG-TIPS Bracket Installation FAQ