Exploring the Benefits and Uses of 0 Degree Siding Nails for Construction Projects

жнів . 14, 2024 14:48

Understanding 0 Degree Siding Nails A Comprehensive Guide

When it comes to installing siding, selecting the right materials is key to achieving a durable and aesthetically pleasing finish. One crucial component of siding installation is the fasteners used to secure the siding panels to the structure. Among the options available, 0 degree siding nails have become increasingly popular due to their unique features and advantages.

What are 0 Degree Siding Nails?

0 degree siding nails are a type of fastener specifically designed for siding applications. The term 0 degree refers to the angle of the nail's head relative to the shank. Unlike other nail types that may be angled (such as 15 or 21-degree nails), 0 degree nails have a straight shank and a flat head. This design allows for greater control during application and makes it easier to keep the siding panels flush against the wall.

Advantages of Using 0 Degree Siding Nails

1. Enhanced Control and Precision The straight shank of 0 degree nails provides better visibility and alignment when nailing. This feature is particularly beneficial for projects that require precise placement of siding panels, ensuring a professional finish.

2. Compatibility with Various Siding Materials 0 degree siding nails are versatile and can be used with various siding materials, including vinyl, wood, and fiber cement. This adaptability makes them a popular choice for contractors who work with multiple types of siding.

3. Reduced Risk of Damage The flat head of 0 degree nails minimizes the risk of splitting the siding material. This is especially important when working with thin or fragile siding options. Additionally, the straight shank allows for a more secure attachment, reducing the likelihood of nails coming loose over time.

4. Efficiency When using a pneumatic nail gun designed for 0 degree siding nails, the speed and efficiency of the installation process is significantly enhanced. This aspect is crucial for professional contractors who are working on tight timelines.

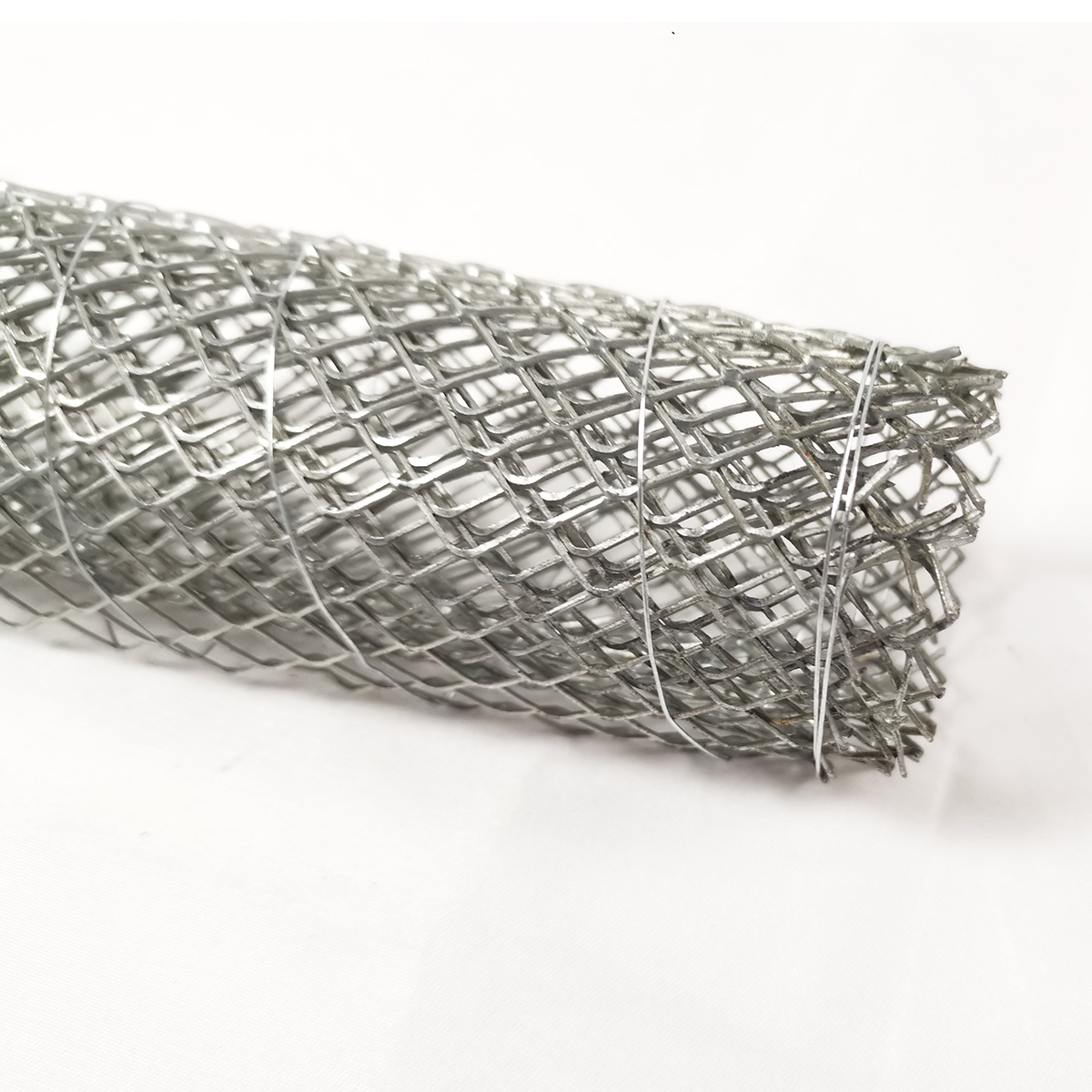

0 degree siding nails

Choosing the Right 0 Degree Siding Nails

When selecting 0 degree siding nails, it is essential to consider the length and gauge. The length will depend on the thickness of the siding material and the underlying structure. A general guideline is to choose nails that penetrate at least 1 inch into the sheathing or framing for a secure hold. The gauge, which indicates the thickness of the nail, should be compatible with the siding material to ensure stability without causing damage.

Installation Tips

1. Correct Spacing When installing siding, it is critical to follow the manufacturer's recommendations for nail spacing. Typically, nails should be placed every 16 to 24 inches, depending on the siding type.

2. Nail Placement Nails should be driven at a slight upward angle, especially in areas subjected to wind or moisture. This technique helps prevent water infiltration and ensures the durability of the siding.

3. Avoid Overdriving One common mistake during installation is overdriving the nails. This can lead to damaging the siding material or diminishing the hold of the nail. Aim for a snug fit that allows the siding to move naturally with temperature changes.

Conclusion

In summary, 0 degree siding nails play an integral role in siding installation. Their unique design offers numerous advantages, including enhanced control, compatibility with various materials, and reduced risk of damage. By understanding the characteristics and best practices for using 0 degree siding nails, homeowners and contractors alike can achieve a quality finish that stands the test of time. As always, following manufacturer guidelines and using the right tools will further ensure a successful siding project. With the right approach, your siding installation can seamlessly blend functionality with aesthetic appeal, ultimately enhancing your home's curb appeal.