Related News

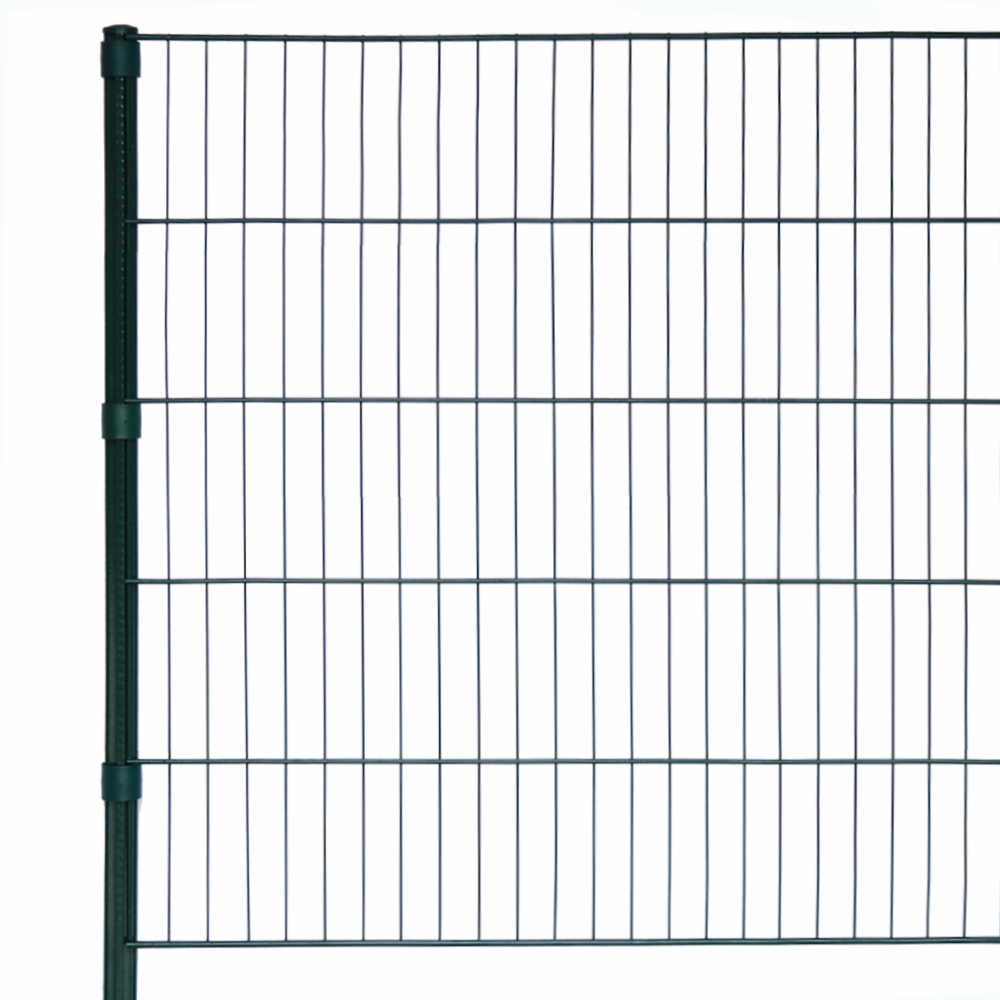

High Quality Euro Fence Panel for Garden & Security Solutions

ліп . 27, 2025 21:01

The euro fence panel (also known as european fence panels, euro style fence, euro steel fence panel) represents a breakthrough in integrated fencing technology, combining aesthetics, strength, durability, and advanced production standards. This comprehensive review details Euro-Panel’s core technical parameters, manufacturing process, industry adoption, third-party certifications, real-world case studies, and advanced data visualization to empower buyers and engineers with actionable insights.

Modern euro fence panel installation in residential environment

1. Industry Overview & Technology Trends

The global euro fence panel market was valued at USD 1.3 billion in 2023 (Statista). Growth is powered by surging demand for high-security, corrosion-resistant, and maintenance-free fencing in residential, industrial, energy, mining, and metropolitan infrastructure sectors.

- Growth: CAGR 5.7% (2023-2028)

- Top buyers: Infrastructure, petrochemicals, water utilities, warehouses, transportation, and eco-smart housing

- Key drivers: Urbanization, perimeter security, anti-corrosion, sustainable construction

- Main players: Euro-Panel (Hebei Metals), Betafence, WireWorks Europe, EuroGuard, Fortress Fence

- Technical innovation: Pre-galvanized steel, powder coating, CNC mesh welding, anti-climb patterns

Automated production of european fence panels at Hebei Metals

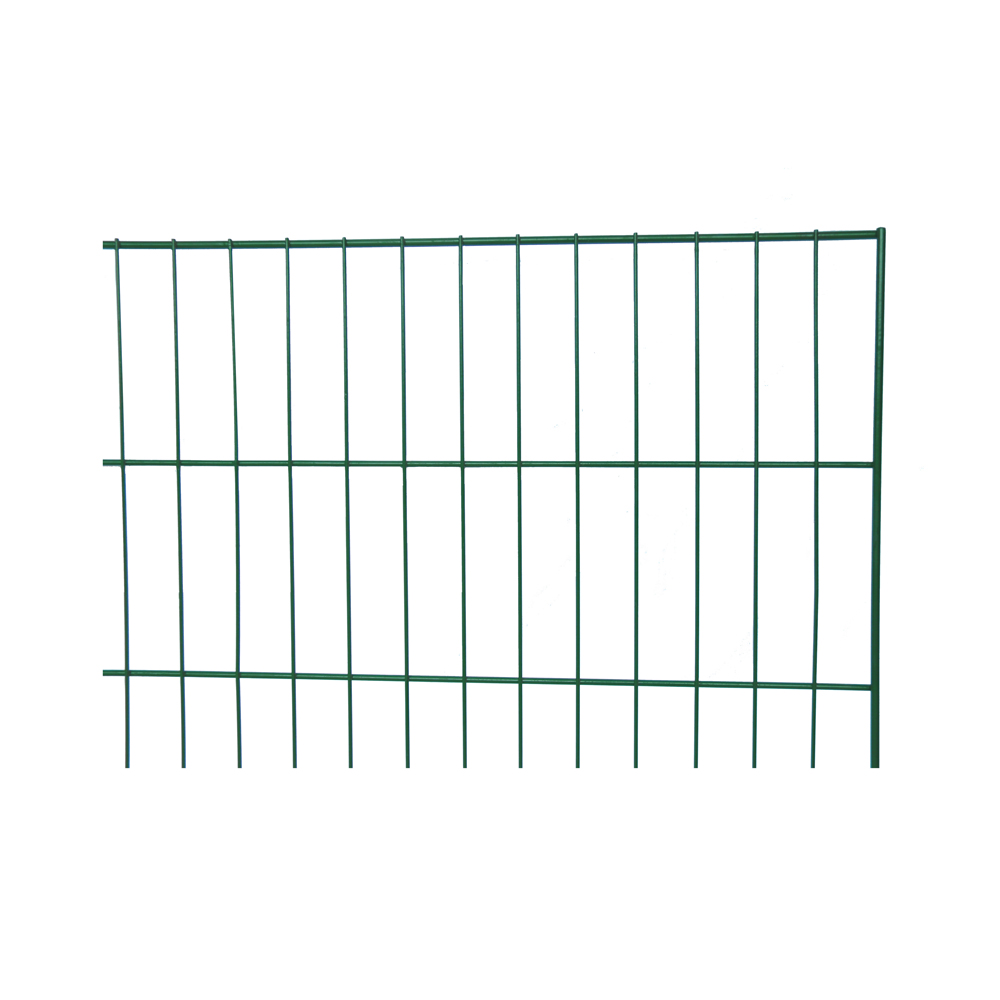

2. Euro-Panel: Product Specs & Core Technical Data

Euro-Panel is the flagship euro fence panel produced by Hebei Metals. Below is a technical parameter snapshot curated from industry databases and datasheets.

| Parameter | Euro-Panel (Standard) | Typical Range | Industry Reference |

|---|---|---|---|

| Panel Height (mm) | 1030 / 1230 / 1530 / 1730 / 2030 | 1030 - 2030 | EN 10223-7 |

| Panel Width (mm) | 2500 | 2000-3000 | Industry Standard |

| Wire Diameter (mm) | 4.0 (+/-0.1) | 3.5 - 5.0 | ISO 16120 |

| Mesh Size (mm) | 50x200 / 55x200 | 50x100 - 55x200 | ANSI/AWS D1.3 |

| Steel Grade | S235JR | S185 - S235JR | EN 10025 |

| Surface Treatment | Pre-galvanized + duplex PVC powder coating (250μm) | Galvanizing / Polyester coating / Hot-dip | ISO 1461 / ISO 12944 |

| Service Life (lab tested) | 30+ years | 20-35 years | SGS Reports/ISO |

| Colors (custom) | Green (RAL6005), Black (RAL9005), Grey (RAL7016) | Any RAL | EU/US color charts |

3. Manufacturing Process of Euro Fence Panel

The below flowchart visualizes the entire lifecycle of a euro fence panel, from steel selection to loading and shipment. State-of-the-art CNC automation, strict test protocols, and EU/ISO standards ensure consistent quality and durability.

1. Raw Steel Sourcing

S235JR certified

→

S235JR certified

2. Wire Drawing/Cutting

Tolerance: ±0.05mm (ISO 16120)

→

Tolerance: ±0.05mm (ISO 16120)

3. CNC Mesh Welding

Robotic precision

→

Robotic precision

4. Surface Treatment

Hot-dip galvanizing → Powder coating (250μm)

→

Hot-dip galvanizing → Powder coating (250μm)

5. QC Inspection

ASTM & ISO 9227 corrosion & adhesion tests

→

ASTM & ISO 9227 corrosion & adhesion tests

6. Pallet Packing & Logistics

For a detailed process video, view here.

CNC mesh welding during euro style fence production

Industry Standards & Certifications

ISO 9001:2015

ISO 1461: Galvanizing

ANSI/AWS D1.3

SGS tested

EU RAL Color Chart

All Euro-Panel products undergo third-party salt-spray (ISO 9227), UV resistance, and destructive testing, surpassing EU’s corrosion standards for european fence panels and major public/industrial projects.

4. Data Visualization: Technical Trends & Product Comparison

Technical parameter trends of euro fence panel (2019-2023)

Distribution of wire diameter preferences (market share %)

Euro-Panel vs Competitor performance rating (out of 10)

Service life projection in typical applications (years)

High-precision euro steel fence panel laboratory testing (ISO/ASTM)

5. Customization & Engineering Solutions

Euro-Panel offers a complete suite of customization:

- Panel Height & Width: 1030 mm – 2030 mm; up to 3000 mm on request

- Wire Diameter: 3.5 mm to 5.0 mm (application-specific)

- Mesh Spacing: 50x200 mm standard; custom on bulk order

- Color: Any RAL code (standard: 6005 green, 9005 black, 7016 anthracite)

- Coating System: Hot-dip galvanized, powder, or duplex composite (salt-spray test: 1000+ hours, ISO 9227)

- Accessories: Integrated posts, anti-climb top rail, secure clamps, privacy wind nets

Service & Lead Time

- Production Capacity: 900,000 sqm/year

- Typical Lead Time: 2-4 weeks EXW/FOB

- Global Logistics: Containerized, ISPM 15 pallets, full traceability

- Warranty: 10 years (surface finishing), up to 30 years (structural)

- After-sales: 24/7 engineering & claims response

Infrastructure project using euro style fence panels for perimeter security

6. Application Scenarios & Case Studies

Euro-Panel is deployed in a wide range of demanding settings. Its technical edge – anti-corrosion, rigidity, and elegant design – makes it ideal for:

- Petrochemical plants (ISO 1461 anti-corrosive fencing for harsh environments)

- Municipal transportation (noise barriers, visual screening)

- Water supply, reservoirs (resistant to moisture, algae, chemicals)

- Industrial estates & warehouses (high security, durability)

- Residential compounds (eco-friendly, modern appearance)

- Schools, parks (safe rounded-tops, tamper-proof joints)

Case Study: Smart City Logistics Park, Rotterdam

- Scope: 8,000 sqm of euro fence panel

- Specs: 1530x2500 mm panel, 4.0 mm wire, RAL7016 (anthracite)

- Demands: Quick install, 30-year corrosion resistance, EN 10223-7 compliance

- Result: Installation finished 23% ahead of schedule, no post-delivery issues after 2.5 years (client feedback available upon request)

Case Study: EMEA Pipeline Project

- Client: Top-tier energy EPC in Middle East

- Solution: Custom euro steel fence panels with enhanced epoxy coating for saline/desert environment

- Certifications: Full set EN 10025 / ISO 9001 test reports supplied

- Benefits: Reduced fence maintenance cost by 48% over 4 years (vs. barbed wire + post alternative)

7. Manufacturer Comparison Table

| Brand | Wire Diameter (mm) | Coating System | Salt Spray Test (hrs) | Avg. Service Life (years) | Certifications |

|---|---|---|---|---|---|

| Euro-Panel | 4.0 ±0.1 | HDG + 250μm Powder | 1000+ | 30 | ISO 9001, ISO 1461 |

| Betafence | 3.8 ±0.1 | Galvanized + PVC | 500 | 20 | ISO 9001 |

| EuroGuard | 4.0 | Galv + Polyester | 700 | 25 | EN 10223-7 |

8. Professional FAQ: Euro Fence Panel Technical Insights

Q1: What is the typical steel material grade for euro fence panel production?

A1: S235JR low-carbon structural steel, certified under EN 10025, offering high weldability, tensile strength & elastic deformation resilience.

Q2: How is product surface corrosion resistance ensured?

A2: Through duplex protection – hot-dip galvanizing (Zn60-120g/m2) plus 250μm powder coating, surpassing ISO 1461 and C5 high-corrosion category, validated by 1000h+ salt spray testing.

Q3: What mesh spacing is optimal for industrial perimeter fencing?

A3: Standard of 50x200mm balances anti-intrusion and cost. Tighter spacings (

Q4: What quality standards do Euro-Panel follow?

A4: ISO 9001 for QMS, ISO 1461 for galvanizing, ISO 9227 for corrosion, ANSI/AWS for welding, EU RAL for color, and periodic SGS/BV third-party lab inspection.

Q5: What installation standards are recommended?

A5: EN 10223-7 and manufacturer instruction SOPs; Euro-Panel also provides custom foundation, post, and fastener design per client geotechnical report.

Q6: Are custom colors and clip accessories available?

A6: Yes – all RAL colors and multiple fastener types (steel/plastic-coated clamps, security screws) available.

Q7: What is the lead time for large projects?

A7: For projects > 5,000 sqm, the lead time is typically 3-5 weeks (production) + shipping, depending on custom requirements and color.

9. Why Euro-Panel – Customer Advantages

- Consistent Quality: Fully automated production, digitalized QC, and traceable batch records

- Industry Recognition: Used by dozens of EPC contractors in Europe, EMEA, South America

- Expert Support: 15+ years technical team for pre-sale consulting, site measurement, and after-sale

- Sustainability: Eco-friendly powder, 99% waste recycling, EU-REACH-compliant raw materials

- Compliance: Full conformity to EU/US standards and project documentation

- End-to-End Service: From model selection to door-to-door logistics and assembly guidance

10. Conclusion & References

The Euro-Panel series stands as an industry benchmark for euro fence panel solutions, thanks to its optimized structural steel, precision CNC production, long-term corrosion performance, and all-in support for engineering-scale projects. By integrating strict European and international standards, it ensures both long lifecycle and compliance for institution, industrial, and urban perimeter security.

References:

[1] Statista: Global fencing market size https://www.statista.com/statistics/1224898/global-fencing-market-size/

[2] SteelConstruction.info "S235JR" Grade: steelconstruction.info/S235

[3] ISO 1461: Hot dip galvanized coatings – iso.org/standard/42883.html

[4] EN 10223-7 Technical info for fencing – iteh.ai/catalog/standards/cen/en-10223-7-2013

[5] Fence Industry Forum: Best practices, corrosion test data – fenceforum.com/best-european-panels/

[6] Practical test data (SGS): Contact upon request.

[7] JD Wire Mesh Association Journal – Trends in perimeter fence tech 2023.

[1] Statista: Global fencing market size https://www.statista.com/statistics/1224898/global-fencing-market-size/

[2] SteelConstruction.info "S235JR" Grade: steelconstruction.info/S235

[3] ISO 1461: Hot dip galvanized coatings – iso.org/standard/42883.html

[4] EN 10223-7 Technical info for fencing – iteh.ai/catalog/standards/cen/en-10223-7-2013

[5] Fence Industry Forum: Best practices, corrosion test data – fenceforum.com/best-european-panels/

[6] Practical test data (SGS): Contact upon request.

[7] JD Wire Mesh Association Journal – Trends in perimeter fence tech 2023.