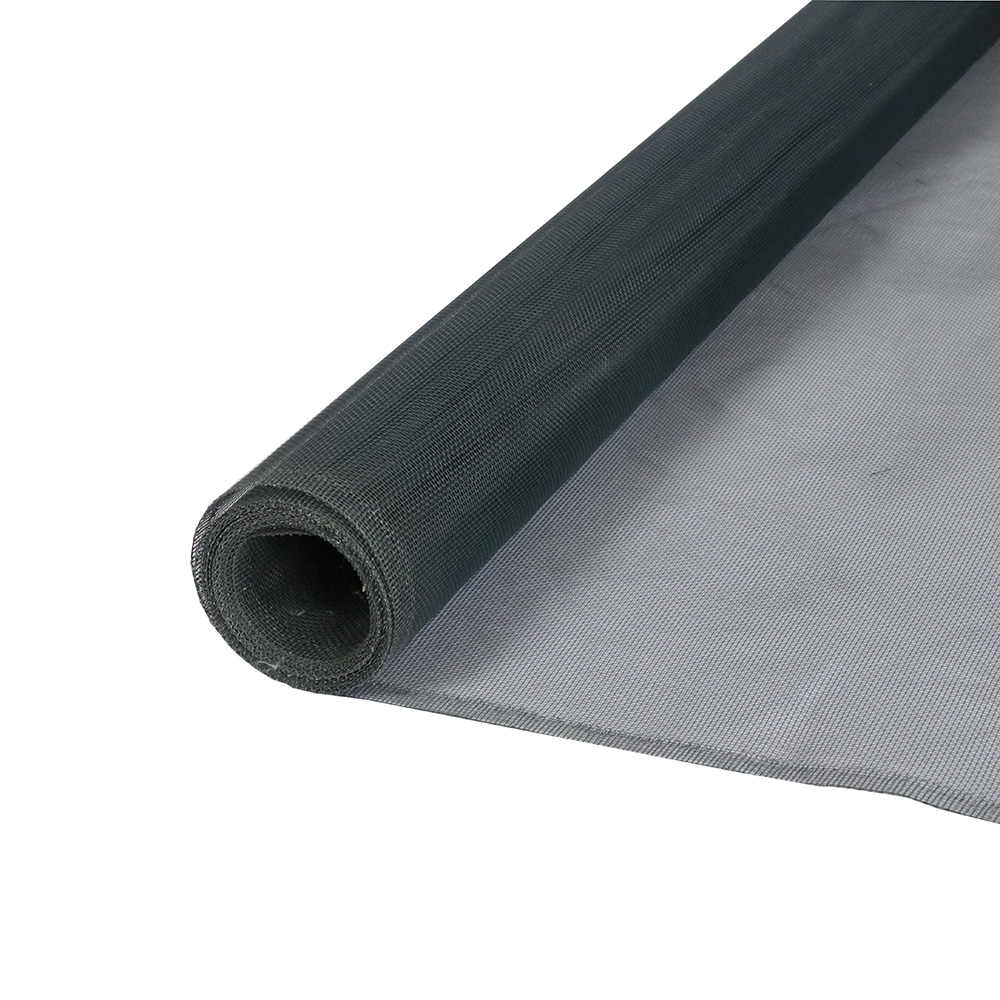

iron mesh screen

снеж . 13, 2024 12:15

The Versatility of Iron Mesh Screens

Iron mesh screens have emerged as essential components in various industrial applications due to their durability, strength, and versatility. Made from woven or welded iron wires, these screens serve multiple purposes in filtration, support structures, architectural designs, and more. Their unique properties make them a popular choice across various industries, including construction, agriculture, and manufacturing.

Material Properties

Iron, as a material, is known for its robust qualities. When used to make mesh screens, it provides an excellent balance between strength and flexibility. The durability of iron ensures that these screens can withstand heavy loads and resist damage from environmental factors. Additionally, iron mesh screens can be coated with materials like zinc to enhance their corrosion resistance, extending their lifespan even in harsh conditions. This resistive capability is particularly valuable in outdoor applications where exposure to moisture and pollutants is common.

Applications in Construction

In construction, iron mesh screens are extensively utilized for both functional and aesthetic purposes. They are commonly used in reinforcing concrete structures. The meshes are embedded in concrete to provide additional strength, prevent cracking, and support load-bearing elements. Moreover, iron mesh is a popular choice for creating guardrails and safety barriers; its strength ensures safety while allowing visibility through the mesh.

Decoratively, iron mesh screens are gaining popularity in modern architecture. Designers often use them for façades, partitions, and railings, adding an industrial aesthetic to buildings while maintaining functionality. The ability to customize the size and weave pattern of iron mesh allows architects to create unique designs that enhance both the exterior and interior of structures.

iron mesh screen

Filtration and Separation

Another significant application of iron mesh screens lies in filtration and separation processes. In agriculture, these screens are used in irrigation systems to filter out debris and prevent clogging of pipes and emitters. They are also employed in the food industry for sifting grains, separating various food products, and ensuring cleanliness in processing facilities.

In industrial settings, iron mesh screens are utilized in various filtration systems to separate solids from liquids or gases. They play a crucial role in water treatment plants, ensuring that the water is filtered adequately before distribution. Their ability to hold up against substantial pressure makes them ideal for use in high-demand filtration applications.

Environmental Considerations

As the world becomes more environmentally conscious, the demand for sustainable materials and processes increases. Iron mesh screens can contribute positively to eco-friendly practices. They are often recyclable, meaning that at the end of their life cycle, they can be repurposed. Moreover, the longevity and durability of iron mesh screens mean that they do not need frequent replacement, reducing waste in various applications.

Conclusion

The iron mesh screen proves to be a versatile and invaluable component in numerous industries. Its strength and durability make it suitable for construction and structural applications. Additionally, its effectiveness in filtration processes highlights its functional capabilities across different sectors. With the increasing focus on sustainability, iron mesh screens present an excellent opportunity to combine performance with eco-friendliness. As technology advances, we can expect further innovations in the production and application of iron mesh screens, ensuring their continued relevance in a wide range of fields. Whether for functional, aesthetic, or sustainable purposes, iron mesh screens are poised to remain a staple material for years to come.