Techniques for Installing a Barbed Wire Fence Efficiently and Effectively

Ліст . 09, 2024 10:05

Running a Barbed Wire Fence A Guide to Maintenance and Safety

Barbed wire fences have been a staple in rural and agricultural settings for decades. They serve multiple purposes including livestock containment, land demarcation, and security. However, maintaining these fences is crucial not only for the utility they provide but also for the safety of animals, people, and the overall landscape. This article will delve into the important aspects of running a barbed wire fence, focusing on maintenance, safety, and best practices.

Understanding the Structure

At its core, a barbed wire fence consists of steel wire strands with sharp barbs at regular intervals. These barbs act as a deterrent for animals and intruders alike. The fence is typically supported by wooden or metal posts, which are set into the ground at set intervals to maintain stability. Depending on the terrain and intended use, barbed wire fences can vary in height and the number of strands used.

Installation Tips

Before running a barbed wire fence, careful planning is crucial. Determine the perimeter you wish to enclose, marking corners with durable stakes. The choice of materials, including the type of wire and posts, will significantly influence the fence's durability. For instance, galvanized wire is known for its resistance to rust and corrosion. Post height should be consistent, with a typical height of 4 to 5 feet above ground.

1. Post Placement Start by placing corner posts deeper in the ground for extra support. Drive them at least 2 feet into the ground and check for vertical alignment.

2. Stretching the Wire Once the posts are in place, the next step involves running the wire. It's essential to stretch the barbed wire properly to prevent sagging. This can be achieved with a wire stretcher tool to ensure tension without compromising the integrity of the wire.

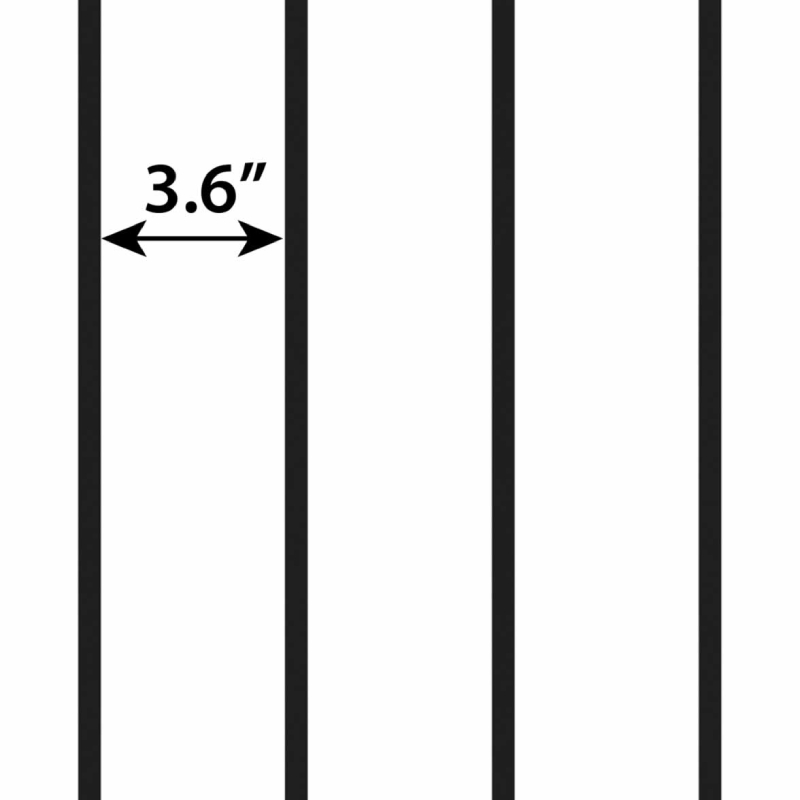

3. Securing the Wire Utilize staples or wire clips to secure the barbed wire to the posts. Ensure that the barbed wire is placed at least 6 inches apart vertically to maximize effectiveness while allowing livestock to graze beneath the bottom strand safely.

Maintenance Protocols

Regular maintenance checks are essential to prolonging the life of your fence

. Here are some key maintenance tasksrunning barbed wire fence

- Inspect for Damage Periodically walk along the fence line to check for rusted sections, loose staples, or broken wires. Repair or replace damaged sections immediately to maintain functionality.

- Tension Adjustments Over time, barbed wire may loosen due to environmental factors. Regularly check and re-tension the wire to ensure it remains taut and effective.

- Weed Control Overgrown vegetation can impede the visibility and effectiveness of a fence. Regularly clear the area around the fence line to maintain visibility and prevent animals from pushing against the wire.

Safety Considerations

Safety is paramount when working with barbed wire. Here are a few tips to ensure a safe working environment

- Protective Gear Always wear gloves and protective eyewear when handling barbed wire to guard against cuts and injuries.

- Educate Others If children or less experienced hands are helping, ensure they understand the dangers associated with barbed wire.

- Clear the Area Before beginning repairs or installations, make sure the area is clear of animals and obstructions to avoid accidents.

Conclusion

Running a barbed wire fence is a valuable skill for anyone involved in agriculture or land management. With proper installation, regular maintenance, and adherence to safety protocols, a barbed wire fence can provide long-lasting service and security. Whether you are containing livestock or marking property lines, a well-maintained barbed wire fence can be an effective tool in any rural setting. Remember a little effort in upkeep goes a long way towards extending the life and effectiveness of your fence.