stainless steel wire mesh

Ліст . 23, 2024 04:13

The Versatility of Stainless Steel Wire Mesh

Stainless steel wire mesh has become an essential material in various industries due to its durability, strength, and resistance to corrosion. Crafted from stainless steel, a remarkable alloy consisting primarily of iron, chromium, and nickel, this mesh is designed to withstand harsh environments while offering an array of functional benefits. In this article, we will explore the characteristics, applications, and advantages of stainless steel wire mesh, illustrating why it is a preferred choice in many sectors.

Characteristics of Stainless Steel Wire Mesh

One of the most significant properties of stainless steel wire mesh is its resistance to rust and corrosion. Unlike regular steel, which can deteriorate when exposed to moisture or corrosive agents, stainless steel retains its structural integrity and appearance over time. This makes it particularly valuable in industries such as food processing, pharmaceuticals, and chemical manufacturing, where hygiene and material integrity are paramount.

In addition to its corrosion resistance, stainless steel wire mesh is known for its high tensile strength. It can support heavy loads without bending or breaking, making it ideal for applications where structural support is necessary. Furthermore, the mesh is available in various grades, including 304, 316, and 430, each offering different levels of strength and corrosion resistance, ensuring that there is a suitable option for every application.

Applications of Stainless Steel Wire Mesh

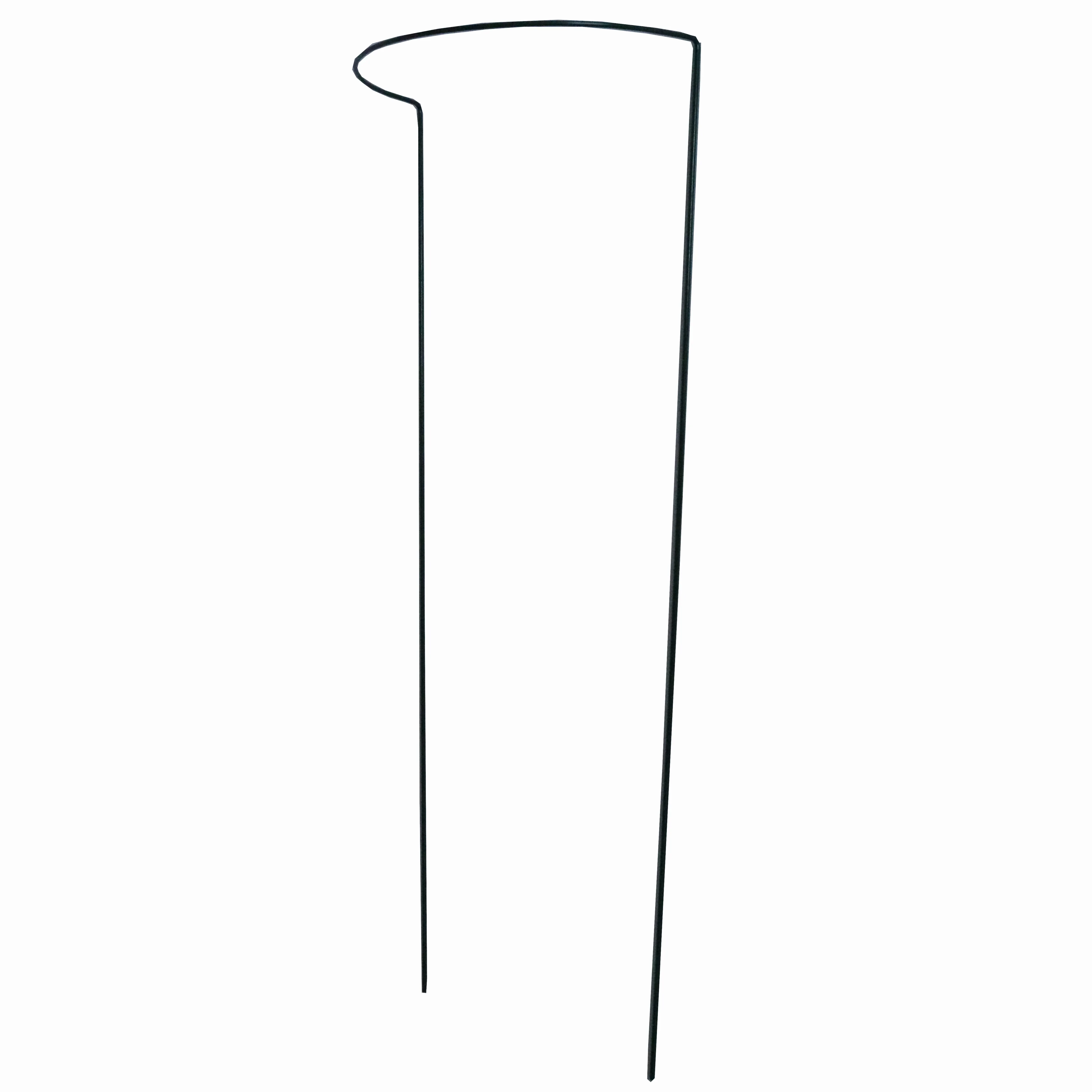

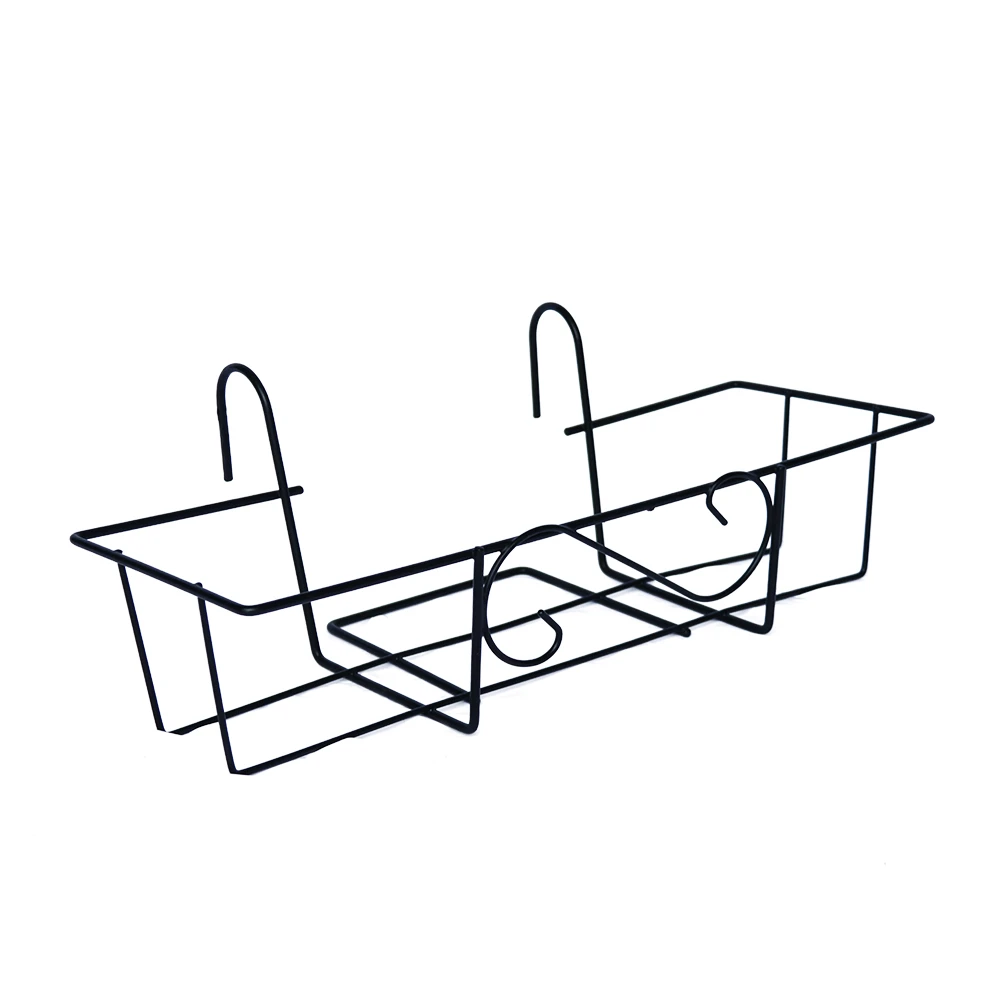

The versatility of stainless steel wire mesh lends itself to numerous applications across various sectors. In the construction industry, it is commonly used for architectural elements, reinforcing concrete, and as a safety barrier in windows and doors. Its strength and aesthetic appeal make it a popular choice for both functional and decorative uses.

In the food and beverage industry, stainless steel wire mesh plays a critical role in filtration and containment

. It is used in the production of dairy products, brewing, and water purification. The mesh's resistance to bacteria growth and cleaning ease ensures that it meets the stringent hygiene standards required in food-related applications.stainless steel wire mesh

Moreover, the automotive and aerospace industries utilize stainless steel wire mesh for manufacturing filters, screens, and shielding components. Its ability to withstand extreme temperatures and pressures while maintaining structural integrity makes it indispensable for these high-performance applications.

Advantages of Using Stainless Steel Wire Mesh

One of the key advantages of stainless steel wire mesh is its longevity. While it may have a higher initial cost compared to other materials, its durability and low maintenance requirements translate to savings over time. Users do not have to worry about frequent replacements or repairs, making it a cost-effective choice in the long run.

Furthermore, the aesthetic flexibility of stainless steel wire mesh allows designers to create innovative and visually appealing installations. It can be fabricated into various shapes and sizes, tailored to meet specific project needs while complementing modern architectural designs.

Lastly, stainless steel wire mesh is environmentally friendly. Its manufacture involves recyclable materials, and the product itself can be recycled at the end of its lifespan, contributing to sustainable practices in manufacturing and construction.

Conclusion

Stainless steel wire mesh is an exemplary material characterized by its strength, durability, and resistance to corrosion. Its diverse applications across numerous industries underscore its significance and reliability. As we continue to prioritize sustainability and efficiency in manufacturing and daily use, stainless steel wire mesh is poised to remain a cornerstone material, providing solutions that meet the demands of modern society. Whether in construction, food production, or engineering, its contributions are invaluable, making it a pivotal choice for builders, manufacturers, and designers alike.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution