warehouse racking system

Ліст . 02, 2024 12:43

Understanding Warehouse Racking Systems A Comprehensive Overview

In today's fast-paced logistics and supply chain landscape, the efficiency of warehouse operations is paramount. One critical component that significantly influences this efficiency is the warehouse racking system. These specialized storage solutions allow businesses to maximize their space, improve accessibility, and enhance inventory management.

Warehouse racking systems come in various designs, each tailored to meet specific operational needs. The most common types include pallet racks, selective racks, drive-in racks, and cantilever racks. Pallet racking is perhaps the most prevalent option, allowing for the storage of palletized goods in horizontal rows, accessible via forklifts. Selective racks offer direct access to each pallet, making them ideal for businesses that require frequent product retrieval. In contrast, drive-in racks enable deeper storage by allowing forklifts to drive into the structure, maximizing the use of vertical space in the warehouse.

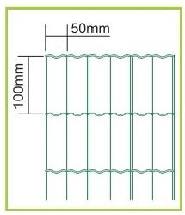

Understanding the dimensions and layout of your warehouse is crucial when choosing a racking system. Proper planning requires consideration of factors such as ceiling height, aisle width, and load capacity. By conducting a thorough analysis, warehouse managers can determine the most space-efficient design that aligns with their operational workflow.

warehouse racking system

Moreover, safety is a key concern when implementing a racking system. Proper installation and regular maintenance of the racks are vital to prevent accidents and ensure the longevity of the structure. It is advisable to train staff on the correct handling procedures to minimize the risk of injuries and damage to goods.

Aside from safety and space optimization, modern racking systems can enhance inventory management. Many businesses now incorporate technology solutions such as barcode scanning and RFID systems into their racking setups. These technologies streamline the tracking of inventory levels, aid in order fulfillment, and ultimately contribute to greater operational efficiency. This integration of technology not only reduces human errors but also accelerates the overall process of managing stock.

As e-commerce continues to rise, the demand for efficient warehouse solutions will only grow. Companies are increasingly seeking customized racking solutions that are flexible and scalable to adapt to changing inventory needs. This adaptability is essential for maintaining competitive advantage in the market.

In conclusion, warehouse racking systems play a crucial role in modern logistics and supply chain management. By selecting the right type of racking, ensuring safety, and incorporating technology, businesses can significantly enhance their operational efficiency. As the landscape of warehousing evolves, investing in an effective racking system will remain a critical factor for success.